Intelligent laser coding device

A technology of laser coding and equipment, which is applied in the field of laser coding, can solve the problems of high operation intensity, inconvenient height adjustment, and low degree of intelligent control, so as to reduce operation intensity, increase left and right adjustment functions, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

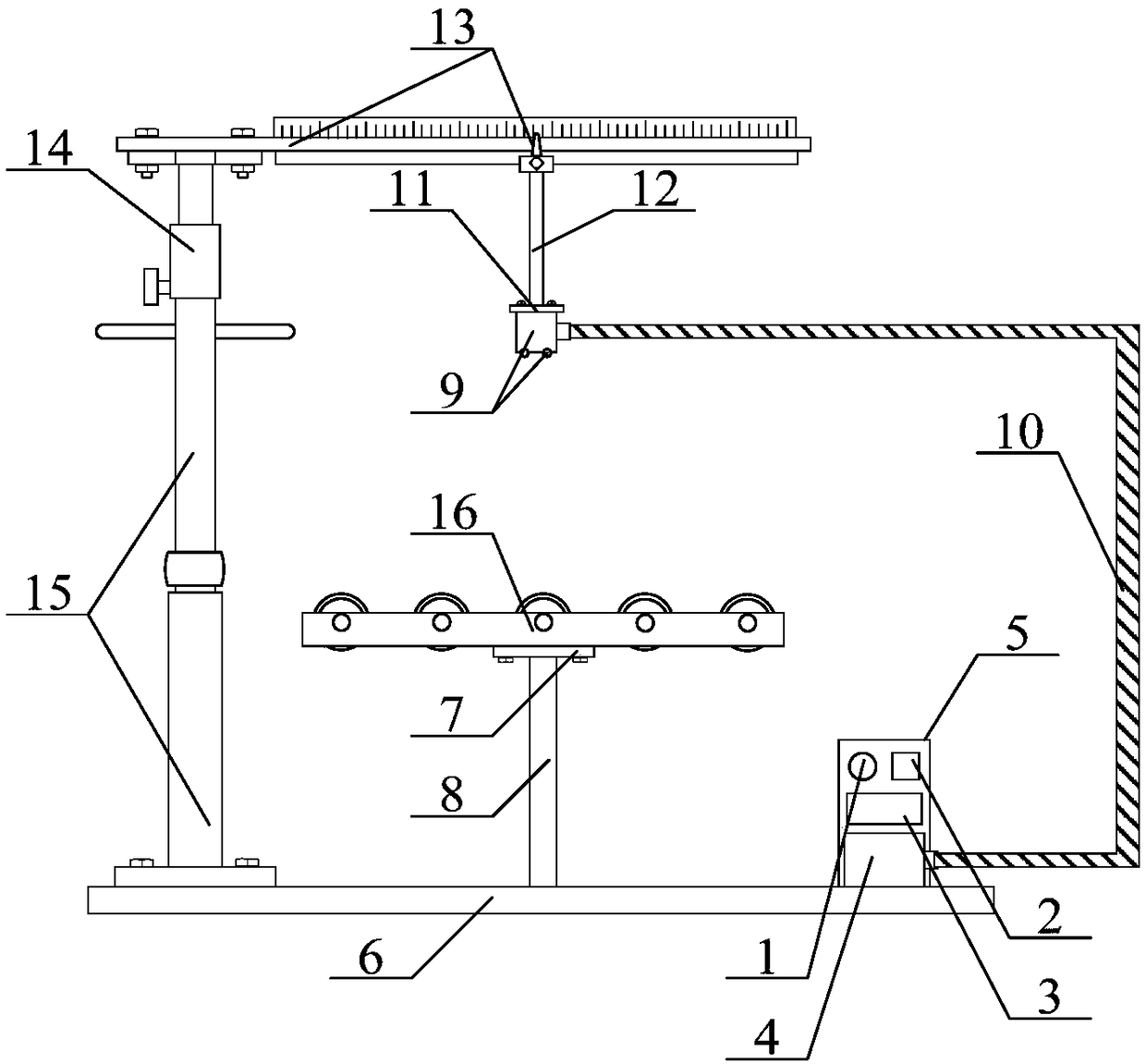

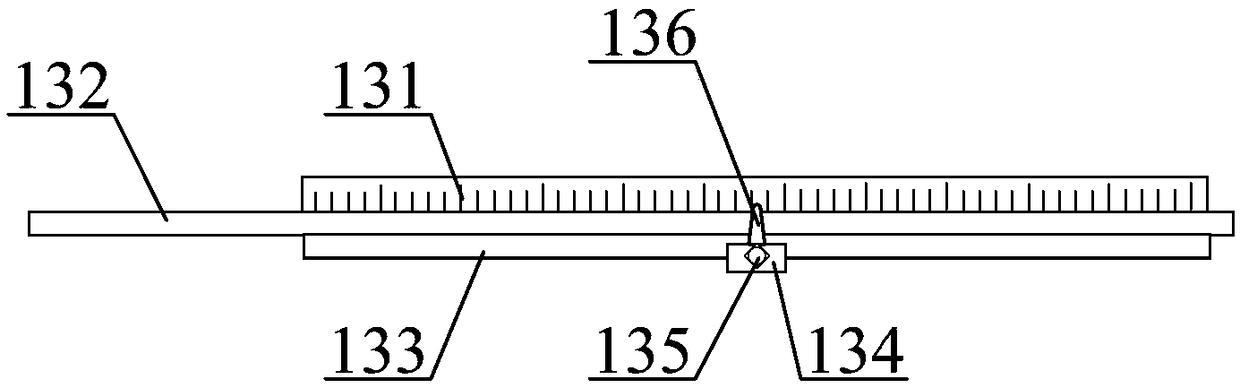

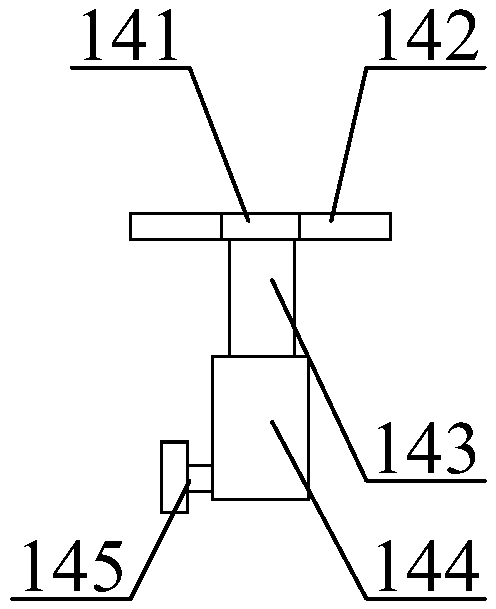

[0042] as attached figure 1 to attach Figure 5 shown

[0043]The invention provides an intelligent laser coding device, which includes an indicator light 1, a master control switch 2, a display screen 3, an intelligent coding host 4, a wiring cabinet 5, a base 6, a fixing seat 7, a support frame 8, Code gun 9, data line 10, connection seat 11, fixed rod 12, movable adjustable fixed rail structure 13, angle rotation adjustment rod structure 14, height adjustment screw structure 15 and coding rolling wheel structure 16, the indicator light 1 Inlaid in the upper left part of the inner side of the wiring cabinet 5; the master control switch 2 is screwed to the upper right part of the inner side of the wiring cabinet 5; the display screen 3 is screwed to the middle of the inner side of the wiring cabinet 5; The intelligent coding host 4 described above is screw-connected to the inner bottom middle position of the wiring cabinet 5; the described wiring cabinet 5 is bolt-connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com