Automotive tail pipe fixing method and flexible fixed support component

A technology for exhaust tailpipes and automobile exhaust, which is applied in exhaust devices, vehicle parts, engine components, etc. to increase efficiency, prevent fatigue damage, and reduce fatigue damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

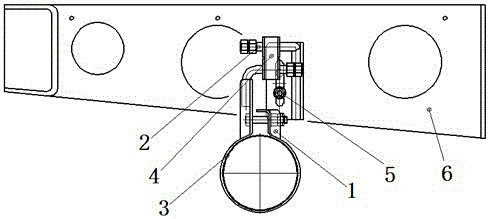

[0038] As shown in the accompanying drawings, a flexible fixing bracket assembly for an automobile exhaust tailpipe includes an exhaust tailpipe hoop 1 and an exhaust tailpipe bracket 2, and the automobile exhaust tail 3 is stuck in the exhaust tailpipe hoop 1 , and then hung on the exhaust tailpipe bracket 2 by the exhaust tailpipe hoop 1; a flexible connector 4 is arranged between the exhaust tailpipe hoop 1 and the exhaust tailpipe bracket 2, and the exhaust tailpipe hugs The hoop 1 is suspended on the exhaust tailpipe bracket 2 through the flexible connector 4, and the exhaust tailpipe bracket 2 is fixed on the vehicle frame 6 through the fastener 5, so that the exhaust tailpipe hoop 1 and the exhaust tailpipe The pipe support 2 is in a flexible connection state, forming a flexible installation.

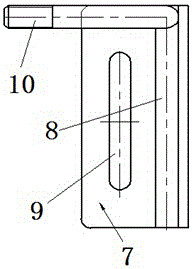

[0039] Wherein, the exhaust tailpipe bracket 2 is a combined metal component, including an "L"-shaped connecting plate 7, and a bracket hanging rod 8 bent into three 90-degree an...

Embodiment 2

[0046] Embodiment 2 has basically the same structure as Embodiment 1. It is a flexible fixing bracket assembly for an automobile exhaust tailpipe, including an exhaust tailpipe hoop and an exhaust tailpipe bracket. Inside the hoop, the exhaust tailpipe hoop is hung on the exhaust tailpipe bracket. There is a flexible connector between the exhaust tailpipe hoop and the exhaust tailpipe bracket. The exhaust tailpipe hoop is The flexible connector is suspended on the exhaust tailpipe bracket, so that the exhaust tailpipe hoop and the exhaust tailpipe bracket are in a flexible connection state, forming a flexible installation.

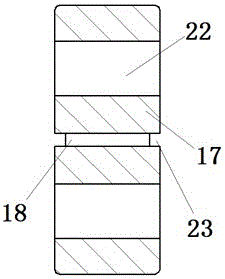

[0047] It’s just that the exhaust tailpipe support is fixed on the vehicle frame by welding, and the flexible connector is a composite member of metal and elastomer; the outer part of the composite member is a metal material shell, and The elastic body is fixed, and there are two composite connection holes in the middle of the elastic body. One of the comp...

Embodiment 3

[0049] The structure of the third embodiment is basically the same as that of the first embodiment. It is a flexible fixing bracket assembly for the exhaust tailpipe of an automobile, including an exhaust tailpipe hoop and an exhaust tailpipe bracket. Inside the hoop, the exhaust tailpipe hoop is then hung on the exhaust tailpipe bracket. The hoop is suspended on the exhaust tailpipe bracket through a flexible connector, so that the exhaust tailpipe hoop and the exhaust tailpipe bracket are in a flexible connection state, forming a flexible installation.

[0050] It is just that the shape of the flexible connector is rectangular, and an elastic body is wrapped in the rectangular shell. The elastic body is a two-body structure and is also a square body. There is a composite connecting hole on each square body. The exhaust tailpipe support can be fixed on the vehicle frame by welding, or fixed on the vehicle frame by fasteners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com