Nut mounting manipulator and nut mounting system

A manipulator and installation hand technology, applied in the field of manipulators, can solve the problems of low work efficiency, low production efficiency, uneven product quality, etc., and achieve the effect of convenient grasping, improving product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

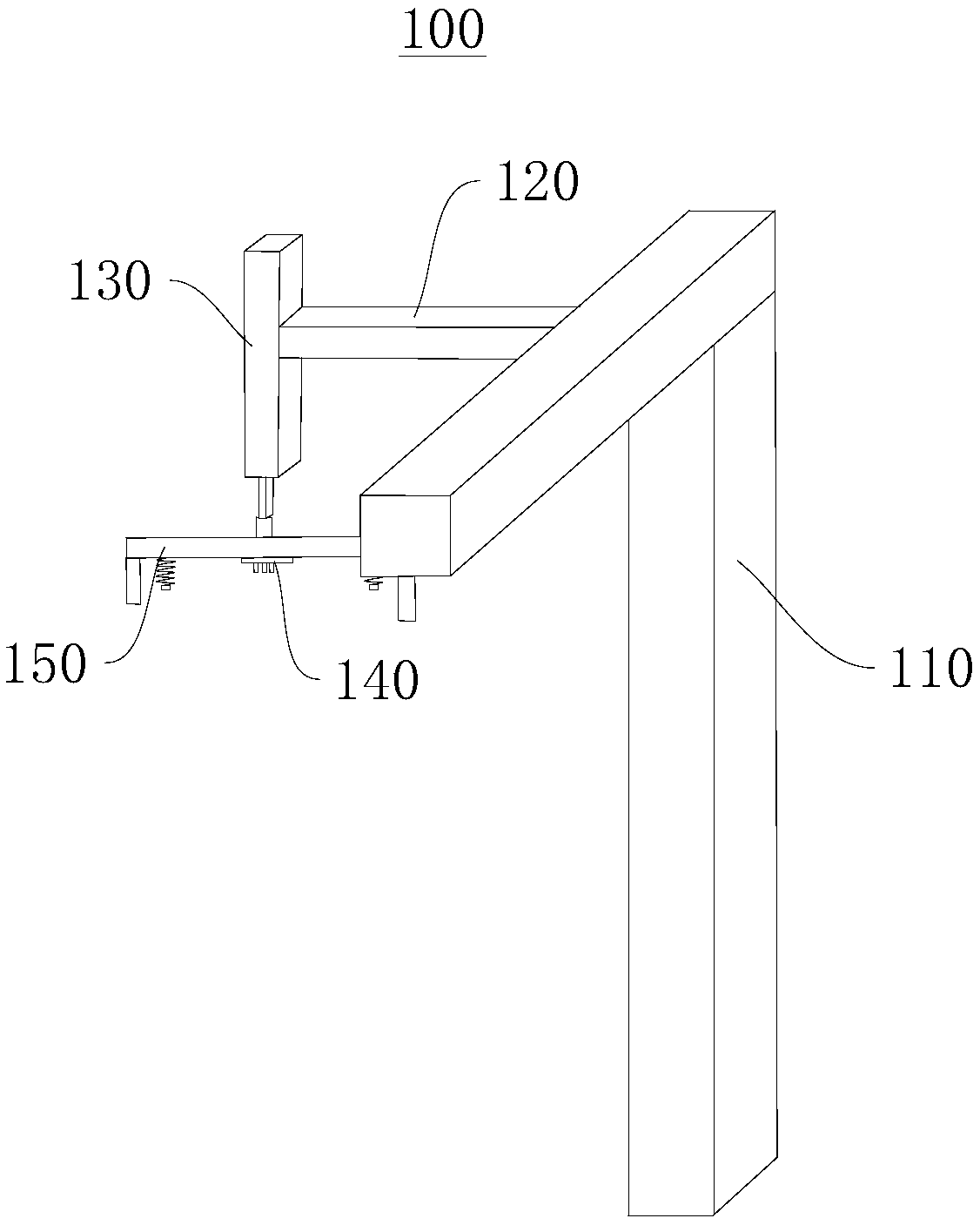

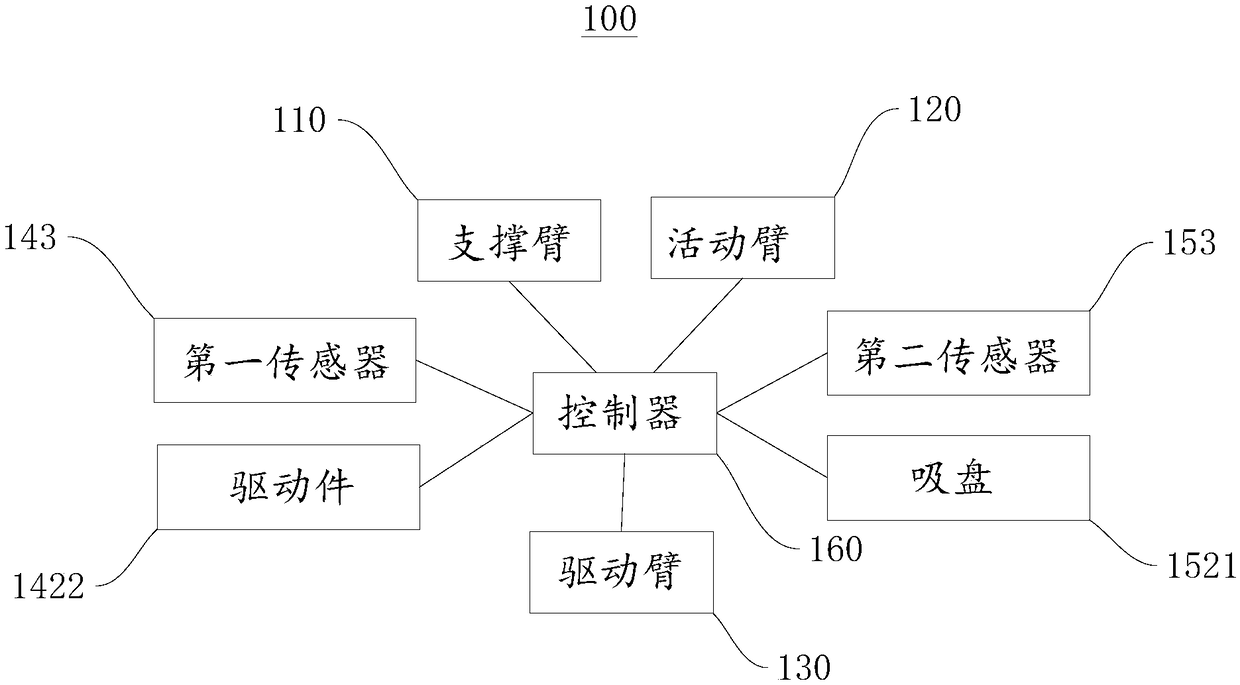

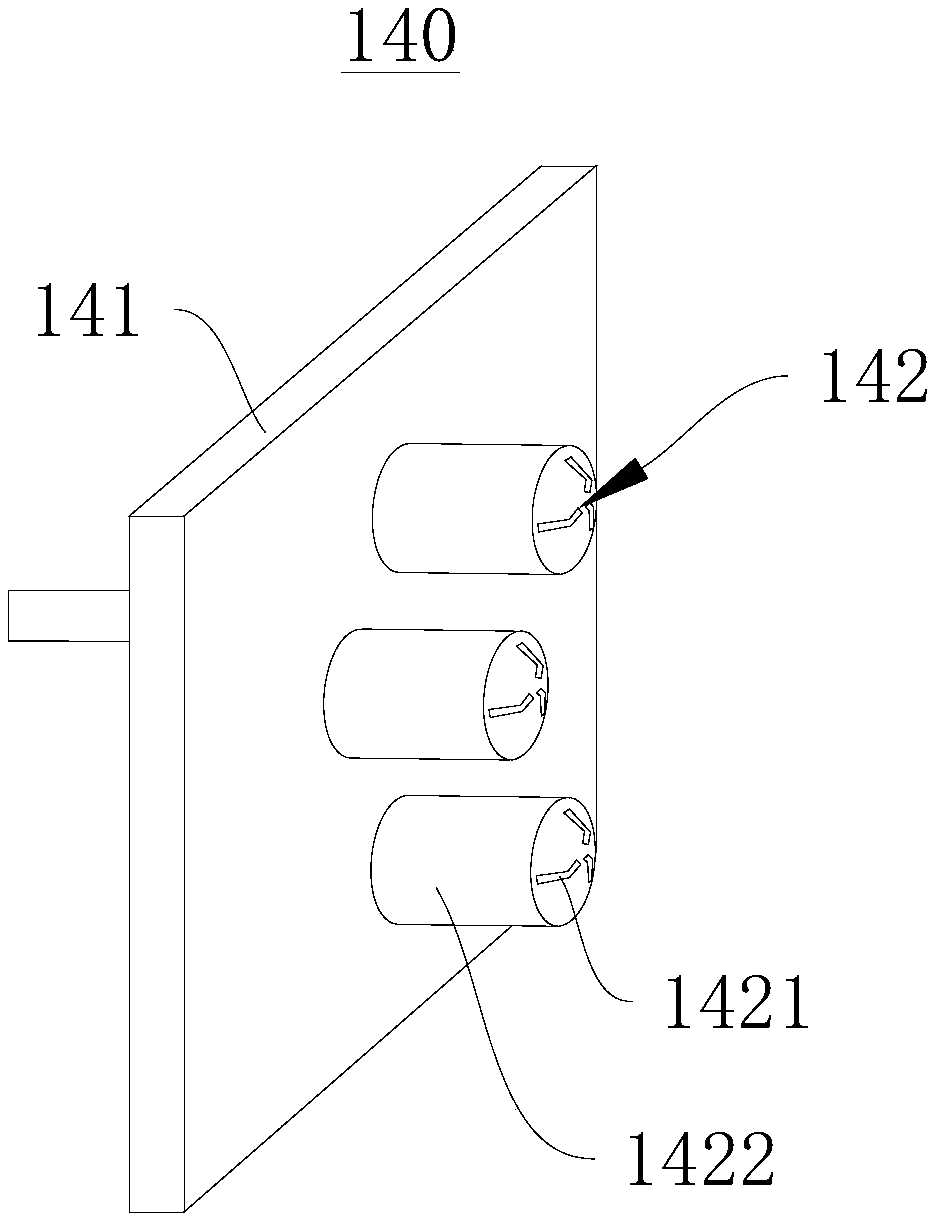

[0040] figure 1 A schematic structural diagram of the nut installing manipulator 100 provided in this embodiment. figure 2 A structural block diagram of the nut installing manipulator 100 provided in this embodiment. Please refer to figure 1 and figure 2 , the present embodiment discloses a nut installation manipulator 100, which is used for grabbing nuts and for grabbing the front beam of the sunroof with the nuts installed.

[0041] The nut installation manipulator 100 includes a support arm 110 , a movable arm 120 , a driving arm 130 , a nut pick-up and install hand 140 , a hand 150 for picking and placing the front beam of the sunroof, and a controller 160 . The support arm 110, the movable arm 120, the driving arm 130, the nut pick-up and installation hand 140 and the sunroof front beam pick-and-place hand 150 are respectively electrically connected to the controller 160 to realize mechanized and automated production.

[0042]In this embodiment, the support arm 110 ...

no. 2 example

[0062] Figure 5 A structural schematic diagram of a sunroof front beam nut installation system 200 provided in this embodiment. Image 6 A structural block diagram of a sunroof front beam nut installation system 200 provided in this embodiment. Please refer to Figure 5 and Image 6 , the sunroof front beam nut installation system 200 includes a feeding mechanism 210 , a loading mechanism 220 , a conveyor belt 230 , a nut installation manipulator 100 and a control system 240 .

[0063] The feeding mechanism 210, the loading mechanism 220 and the nut installing manipulator 100 are arranged at intervals, the conveyor belt 230 is arranged between the feeding mechanism 210 and the loading mechanism 220, the feeding mechanism 210, the loading mechanism 220, the conveyor belt 230 and the nut installing manipulator 100 are electrically connected to the control system 240 respectively. connect.

[0064] The feeding mechanism 210 is used to transport the nuts and keep the nuts in ...

no. 3 example

[0071] Figure 7 The flow chart of the method for controlling the nut installation system provided in this embodiment. The nut installation system control method disclosed in this embodiment is applied to the sunroof front beam nut installation system 200 disclosed in the second embodiment, and the structure of the sunroof front beam nut installation system 200 will not be repeated here.

[0072] The nut installation system control method includes:

[0073] Step S110: Control the action of the nut installation manipulator 100, so that the nut pick-up and installation hand 140 grabs the nuts in the vertical state conveyed by the feeding mechanism 210;

[0074] Step S120: Control the action of the nut installation manipulator 100 to install the nut on the second mold 223, and further control the nut installation manipulator 100 to move away from the second mold 223;

[0075] Step S130: controlling the first mold 221 to approach the second mold 223 to install the nut on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com