Nylon pipe cutting device and nylon pipe cutting method

A cutting device, nylon tube technology, applied in metal processing and other directions, can solve the problems of difficult to achieve fixed-length cutting, nylon tube is easy to rebound and bend, slow cutting speed, etc., and achieves a simple structure, high cutting efficiency, and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

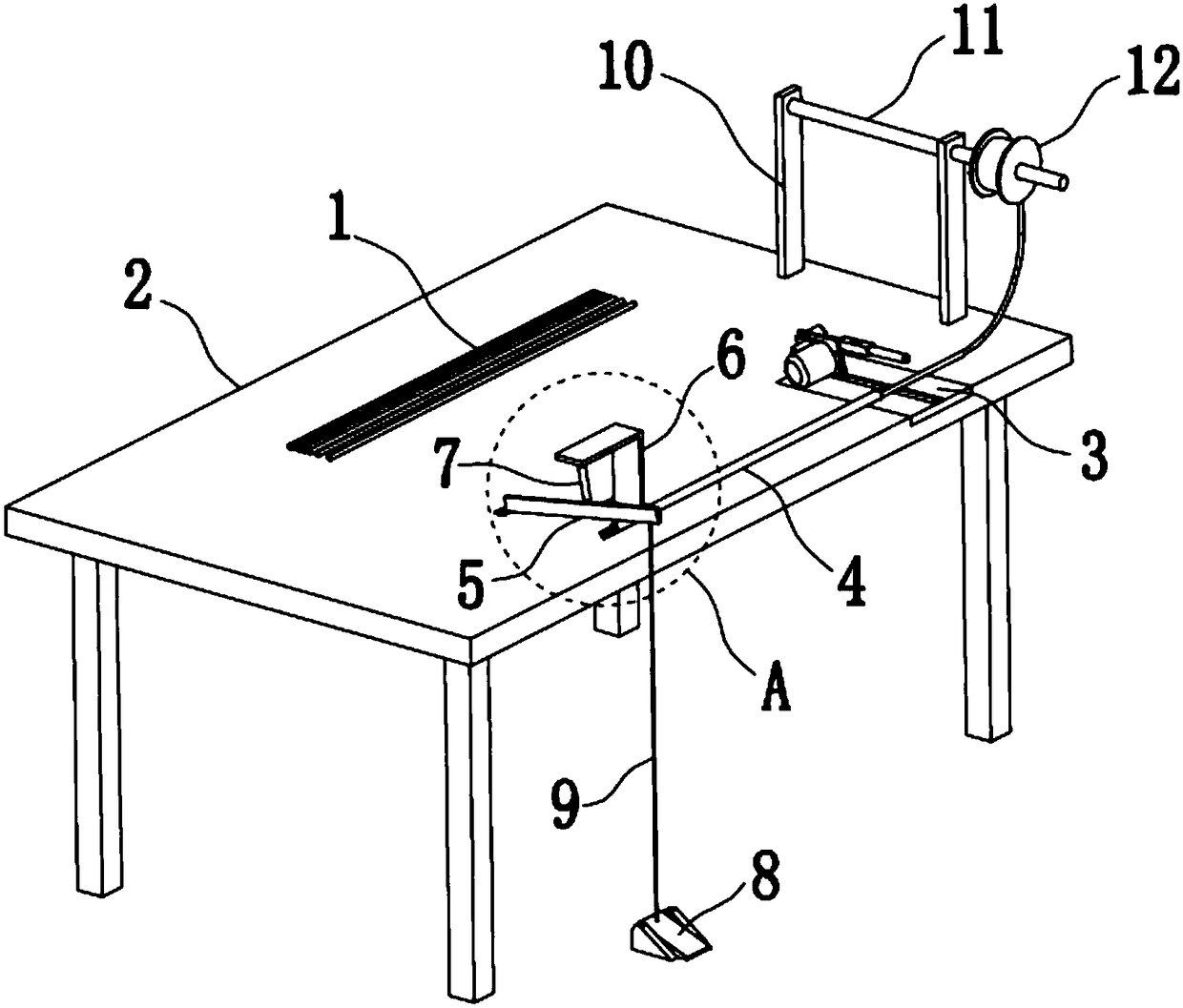

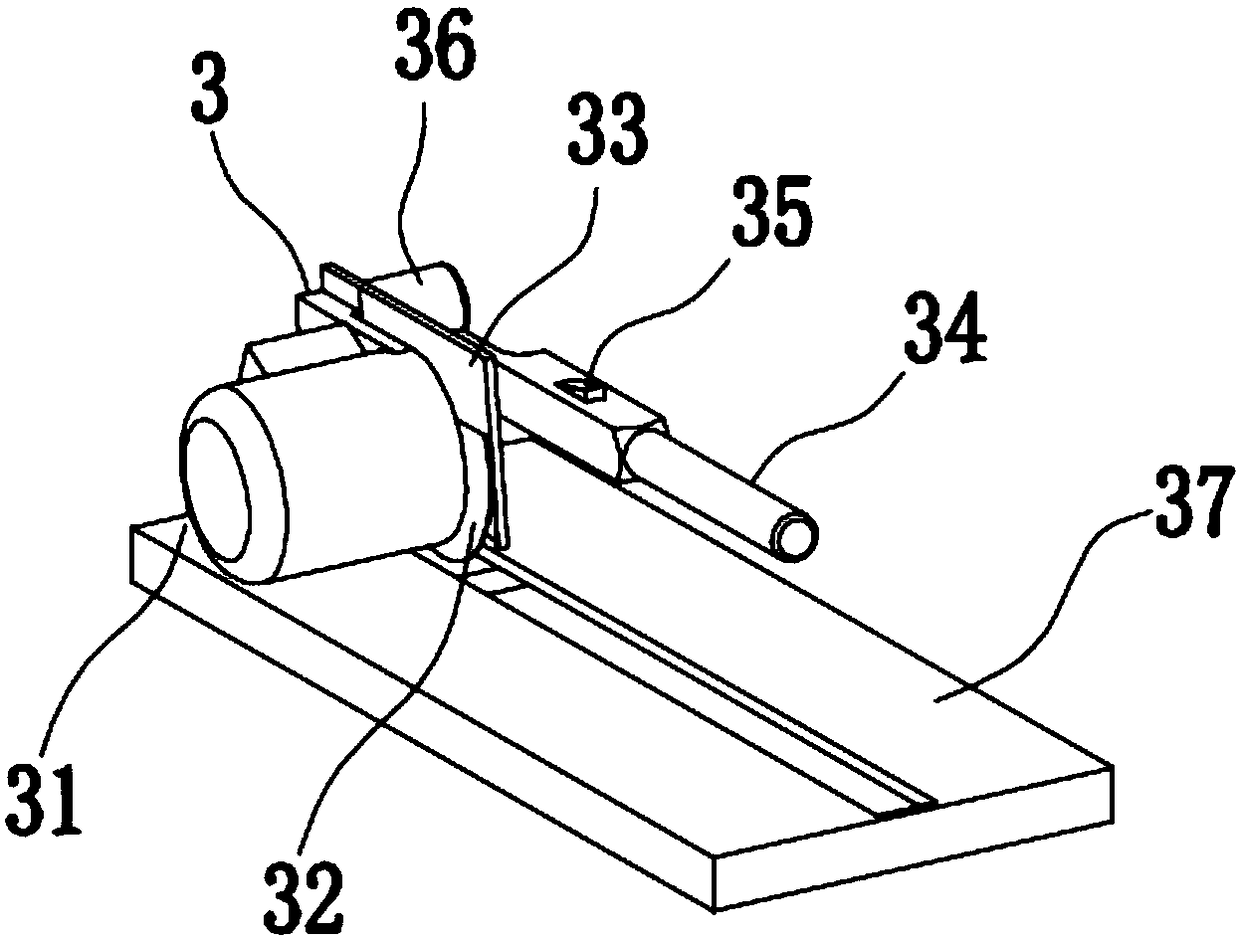

[0052] A nylon tube cutting device such as figure 1 As shown, it includes a workbench 2, and the workbench 2 is sequentially provided with a coil holder, a cutting device 3, a guide pipe 4 and a baffle mechanism; the guide pipe 4 is arranged horizontally, and the cutting device 3 is arranged on the The inlet end of the guide pipe 4, the baffle mechanism is arranged on the outlet end of the guide pipe 4, in this embodiment, the inlet end of the guide pipe 4 is located on the right side of the workbench 2, and the outlet end is located on the left side of the workbench 2 side.

[0053] Described material roll frame is used for placing nylon tube material roll 12, as figure 1 As shown, the nylon tube material roll 12 is hung on the material roll frame, on the one hand, it is convenient to pull the nylon tube extension end on the nylon tube material roll 12, and then the material is cut, and the production efficiency is improved; On the one hand, avoid the random placement of th...

Embodiment 2

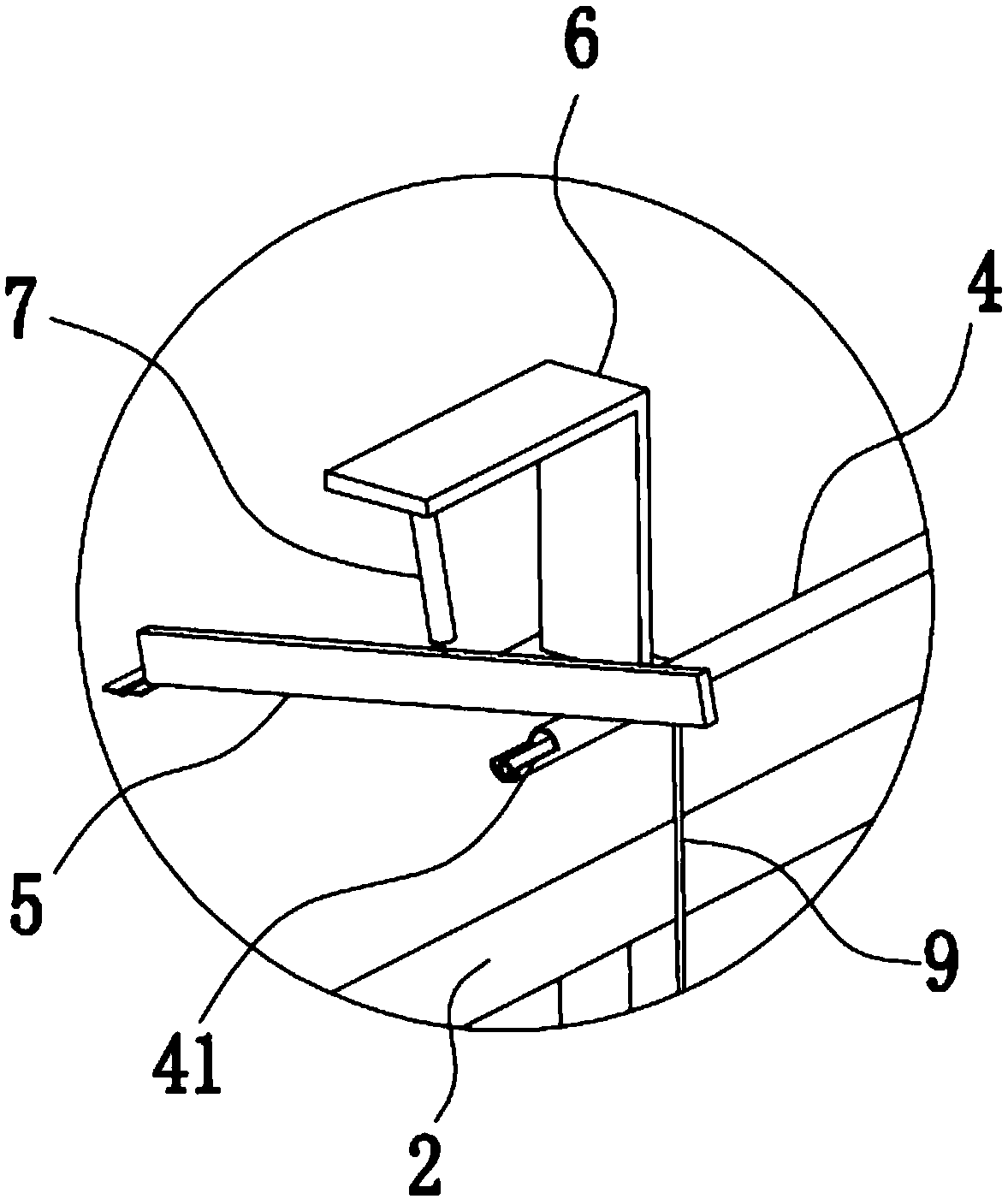

[0059] A kind of nylon tube cutting device of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are, as figure 2 As shown, the outlet end of the guide pipe 4 is provided with a cutout 41, and the cutout 41 is formed by horizontally cutting the upper half of the outlet end of the guide pipe 4 along its axis. Setting the notch 41 can facilitate observation of the position of the end of the nylon tube, and then determine whether the end of the nylon tube is stretched in place; at the same time, it is convenient to take out the nylon tube material section 1 from the guide tube 4 to improve production efficiency.

Embodiment 3

[0061] A kind of nylon pipe cutting device of the present embodiment, basic structure is the same as embodiment 1 or 2, and difference and improvement are, as figure 1 As shown, the coil rack includes a column 10 and a cross bar 11 , the column 10 is vertically fixed on the workbench 2 , and the cross bar 11 is arranged longitudinally and horizontally on the upper end of the column 10 . In this embodiment, there are two columns 10, which are longitudinally distributed on the workbench 2, and the crossbar 11 is arranged on the upper end of the column 10, and is connected with the column 10 through a bearing, so that the crossbar 11 can be rotated, and the front end of the cross bar 11 extends out of the column 10 at the front side, and extends to the front side of the workbench 2 , and the cross bar 11 is used for hanging the nylon tube roll 12 . When cutting, hang the nylon tube material roll 12 on the cross bar 11, pull the nylon tube extension end, drive the nylon tube mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com