A kind of injection molding manipulator and injection molding method

A technology of manipulator and injection molding machine, applied in coating and other directions, can solve problems such as low work efficiency, and achieve the effect of improving work efficiency and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

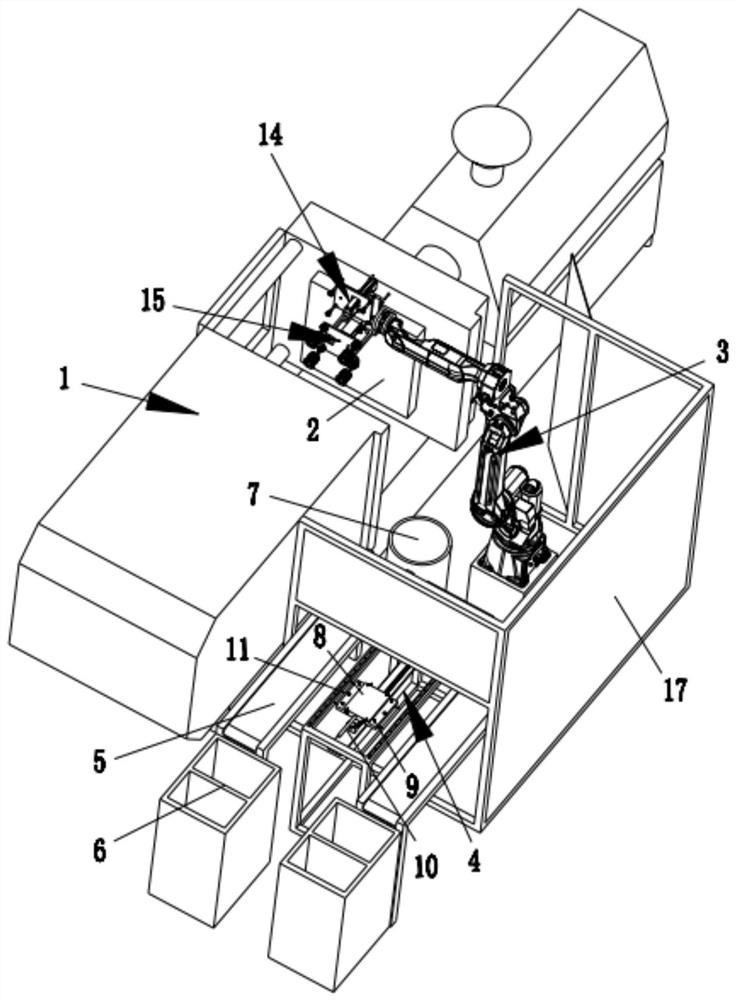

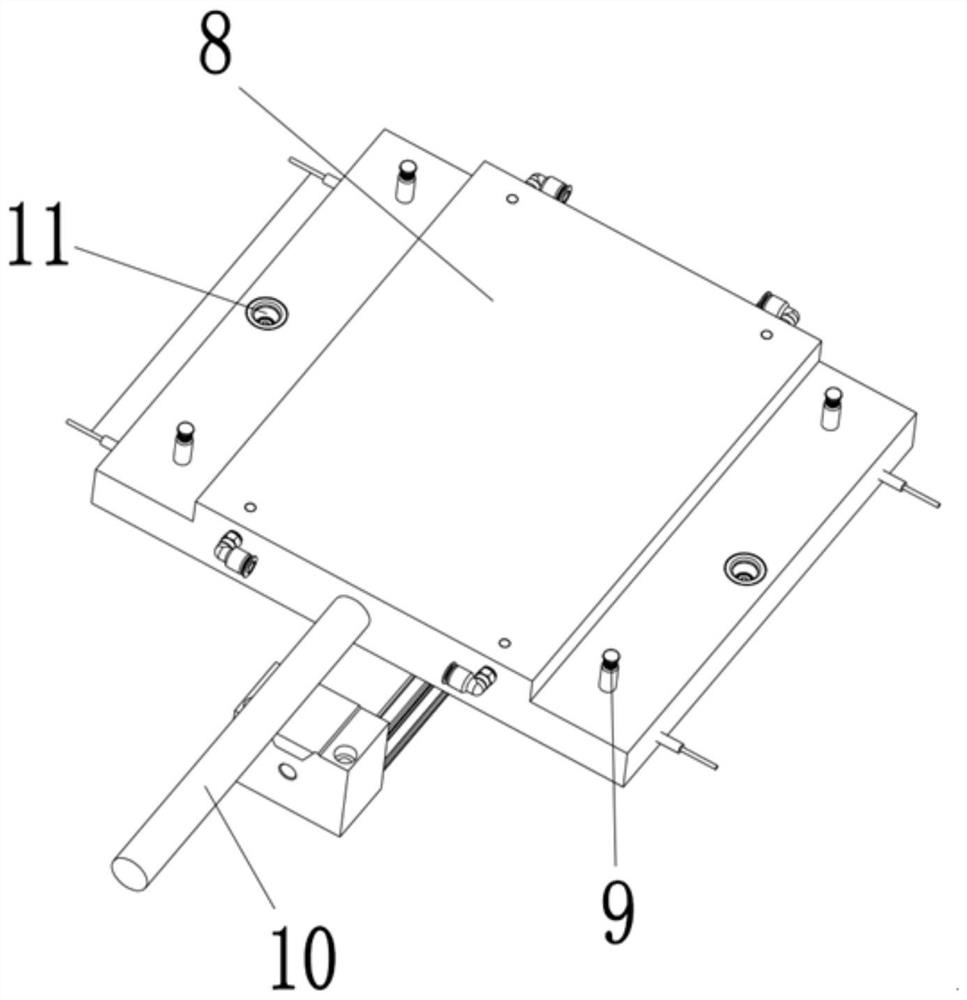

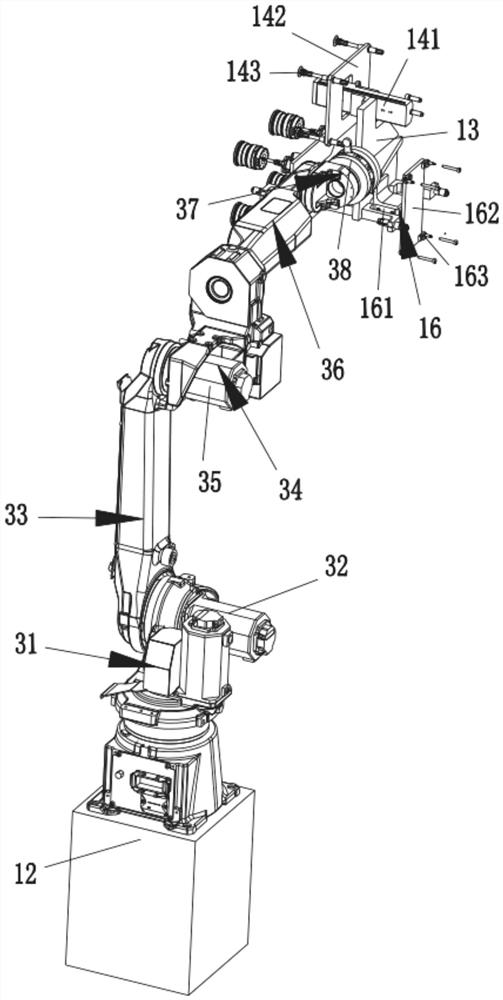

[0025] Embodiment one, such as Figure 1 to Figure 4 As shown, an injection molding manipulator includes an injection molding machine 1 and a mold 2 arranged on the injection molding machine 1, and a manipulator 3 corresponding to the mold 2 is provided on the side where the injection molding machine 1 operates, and the manipulator 3 One side of the frame 4 is provided with a material carrier 4, and the upper end of the material carrier 4 is provided with a shifting mechanism that can move the parts. A feeding belt 5 and a feeding motor are arranged between the shifting mechanism and the injection molding machine 1. A material detection workbench 6 is provided, and a defective product device box 7 is arranged between the shifting mechanism and the manipulator 3. The shifting mechanism includes a shifting support frame, and a slide rail is provided at the upper end of the shifting support frame. A displacement plate 8 is fitted on the rail, and a number of detection sensors are...

Embodiment 2

[0032] Embodiment 2, a divider assembly method, comprises the following steps:

[0033] a. To place the parts, place the parts manually in the limiting concave hole 11 on the shift plate 8, and use the vacuum suction nozzle 143 to place and position the parts in the limiting concave hole 11, if the leakage occurs through the vacuum pressure and flow rate Monitoring and alarming, if it is put too much, it will run out of the limit concave hole 11;

[0034] b. To move the parts, the shifting plate 8 is controlled by the shifting cylinder 10 to move forward along the slide rail to the grasping position of the manipulator 3, and the manipulator 3 grabs the parts and moves to the direction of the mold 2. Specifically, the suction nozzle is controlled by the parts pick-and-place cylinder 141 143 moves down to contact with the parts, and then sucks the parts through the suction nozzle 143, and then the manipulator 3 controls the parts pick-and-place device 14 to move to the mold 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com