Method for processing material piling and taking machine track by using tools

A reclaimer and track technology, applied in the field of mechanical processing, can solve problems such as low quality accuracy, poor economy, and difficult manufacturing, and achieve the effects of complete process, excellent product quality, and improved installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

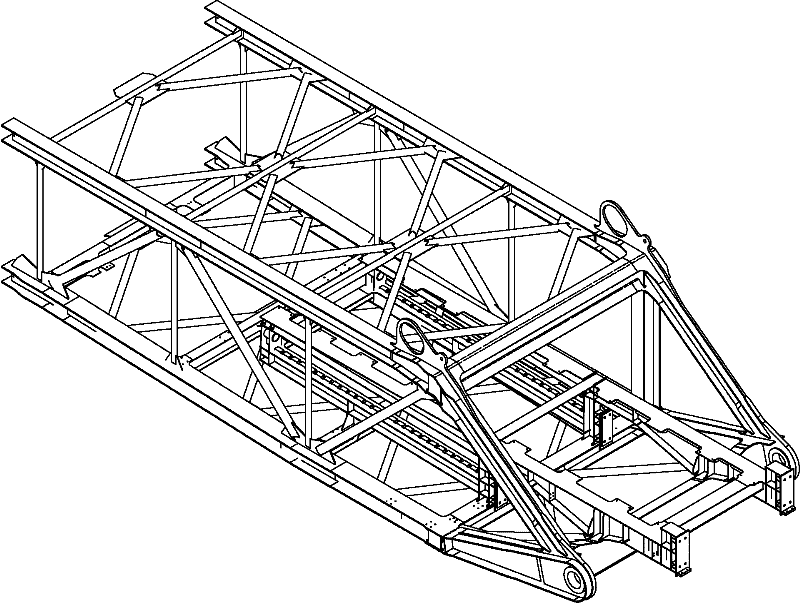

[0014] Embodiment 1 A method for processing the track of a stacker-reclaimer with tooling, including the processing and welding of the track, is characterized in that the process of processing the track of a stacker-reclaimer with tooling is as follows: (1) Rough machining track blanks: eliminate Deformation caused by heating of the material during the blanking process; (2) separate processing: machining and welding are carried out crosswise, and when the racks are not assembled together, the rails are welded to the corresponding racks by welding tool I; (3) ) Track finishing: The track is finished according to the requirements to meet the requirements of size, roughness and shape tolerance; (4) Assembly welding: use welding tool II and welding tool III to ensure the relative position accuracy, and separate the four parts where the track is located The shelf groups are welded together.

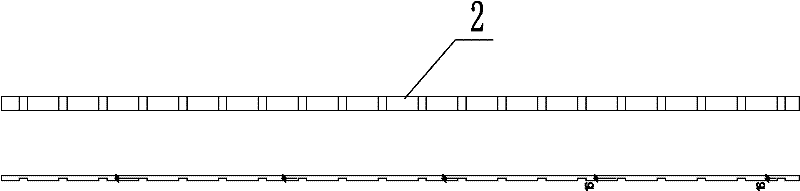

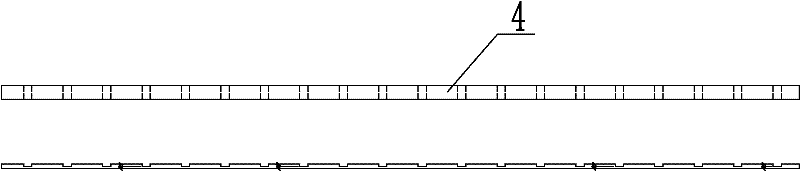

[0015] The welding tooling I is provided with positioning blocks, bolts and nuts, and a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com