Lamp tube forming mold

A technology for forming molds and lamps, applied in glass forming, glass reshaping, manufacturing tools, etc., can solve the problems of increasing lamp production costs, reducing production efficiency, and predicting high energy consumption, and saving preheating energy consumption , Improve work efficiency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

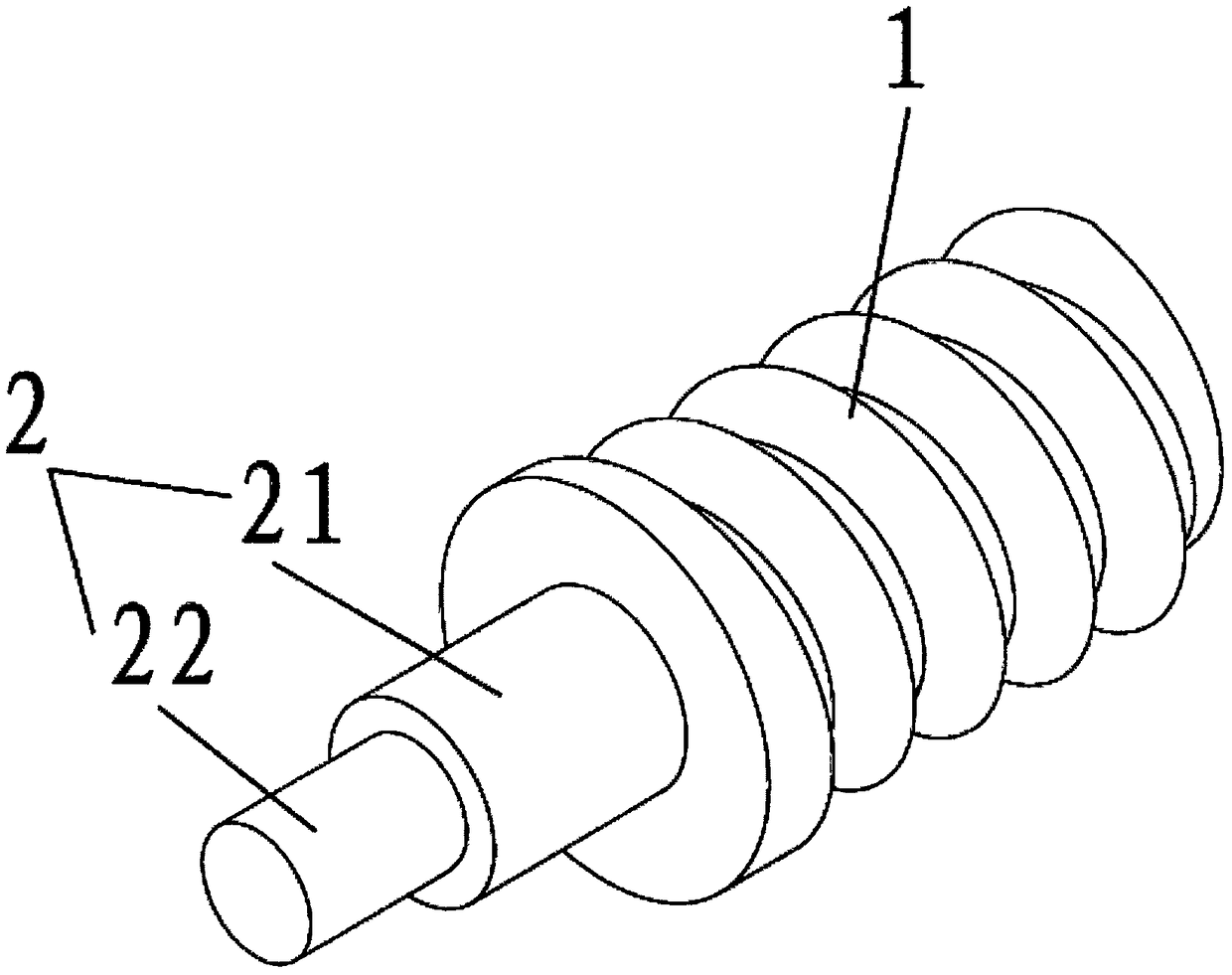

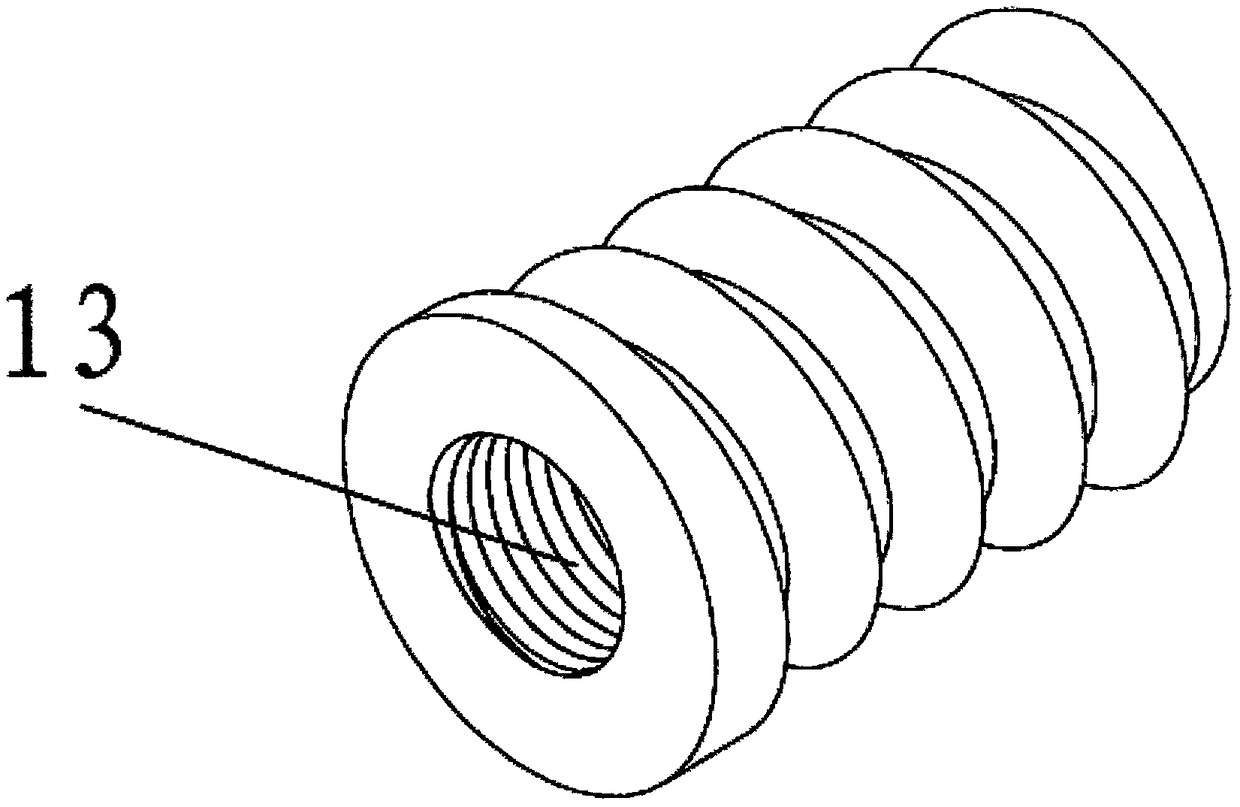

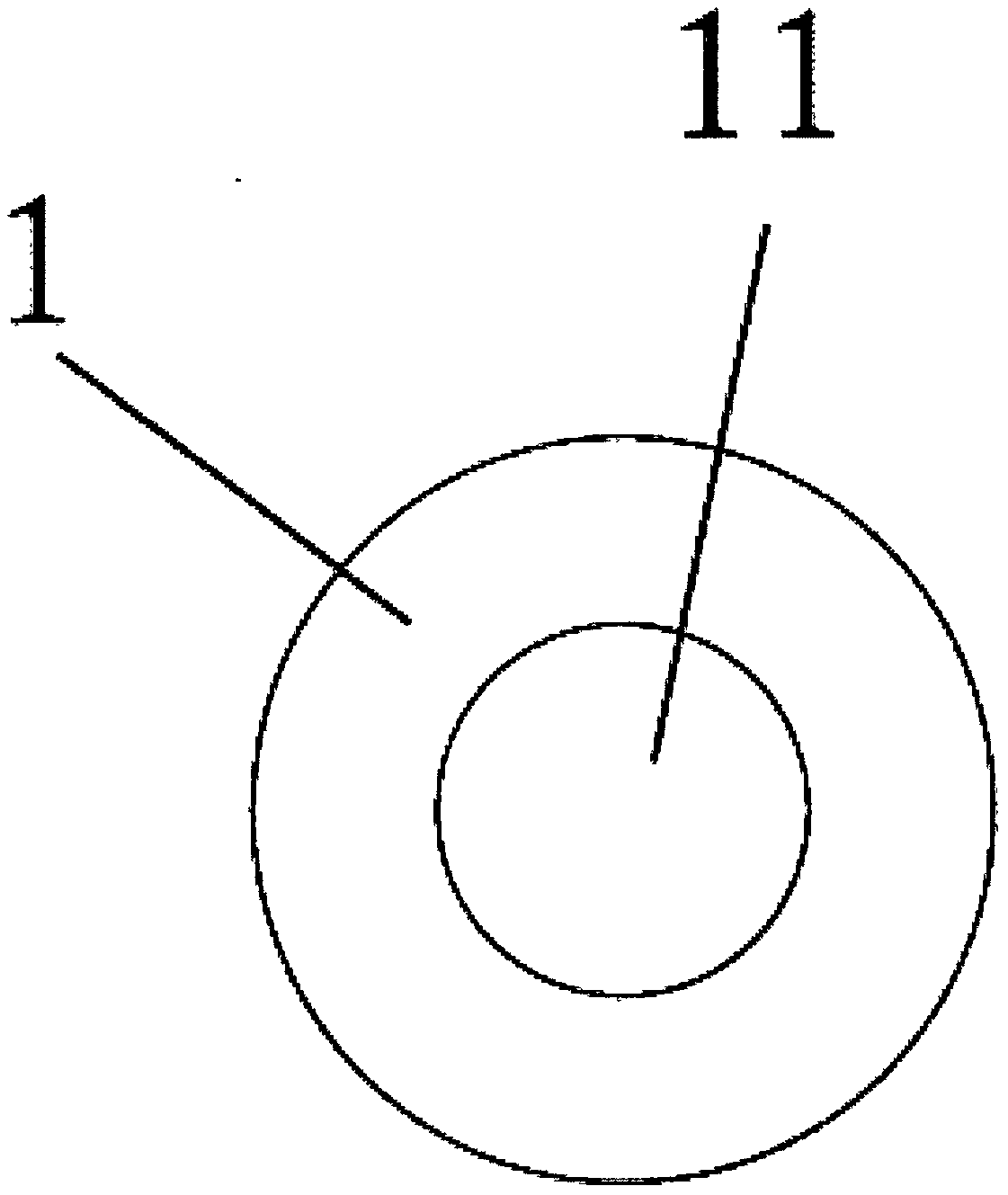

[0030] A lamp tube forming mold includes a mold main body 1 and a connecting shaft 2 arranged on the mold main body 1 for moving or rotating the mold main body 1, in which a cylindrical cavity 11 is provided. The connecting shaft 2 is detachably connected with the mold main body 1. The mold main body 1 is provided with two through holes 12 that allow the inside and outside of the cavity 11 to communicate with each other in air flow. The connecting shaft 2 and the through hole 12 are respectively arranged at both ends of the mold main body 1. The mold main body 1 is provided with a connecting port 13 with an internal thread, and the connecting shaft 2 is provided with an external thread adapted to the internal thread. The connecting shaft 2 is divided into a connecting section 21 that is close to and connected to the mold body 1 and has a larger diameter, and a transmission section 22 that is far from the mold body 1 and has a smaller diameter. The diameter of the cavity 11 is...

Embodiment 2

[0032] The difference from the foregoing embodiment is that there are four through holes, and the diameter of the cavity 11 is 3 / 4 of the diameter of the mold body. The diameter of the through hole 12 is 1 / 5 of the diameter of the cavity 11.

[0033] The cavity 11 provided in the mold reduces the material used for the mold and reduces the material cost, and the preheating time is shortened from 1 hour to 10-20 minutes, which improves work efficiency, saves preheating energy consumption and reduces costs .

[0034] The connecting shaft 2 and the mold main body 1 can be processed separately, which is convenient for processing. The connecting shaft 2 and the mold main body 1 can be replaced separately after being damaged, and only the connecting shaft 2 or the mold main body 1 can be produced separately according to the needs when the mold is produced, which reduces the replacement cost from both aspects. At the same time, different models of molds only need to replace the mold main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com