A kind of organosilicon modified hollow ceramic microbead and its preparation and application

A technology of ceramic microbeads and organic silicon, which is applied in the field of building decoration materials, can solve the problems of ceramic microbead damage, microbead damage, frontal collision of dispersion paddle microbeads, etc., to improve the thermal insulation performance of porcelain, reduce shrinkage, and reduce The effect of loss on ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

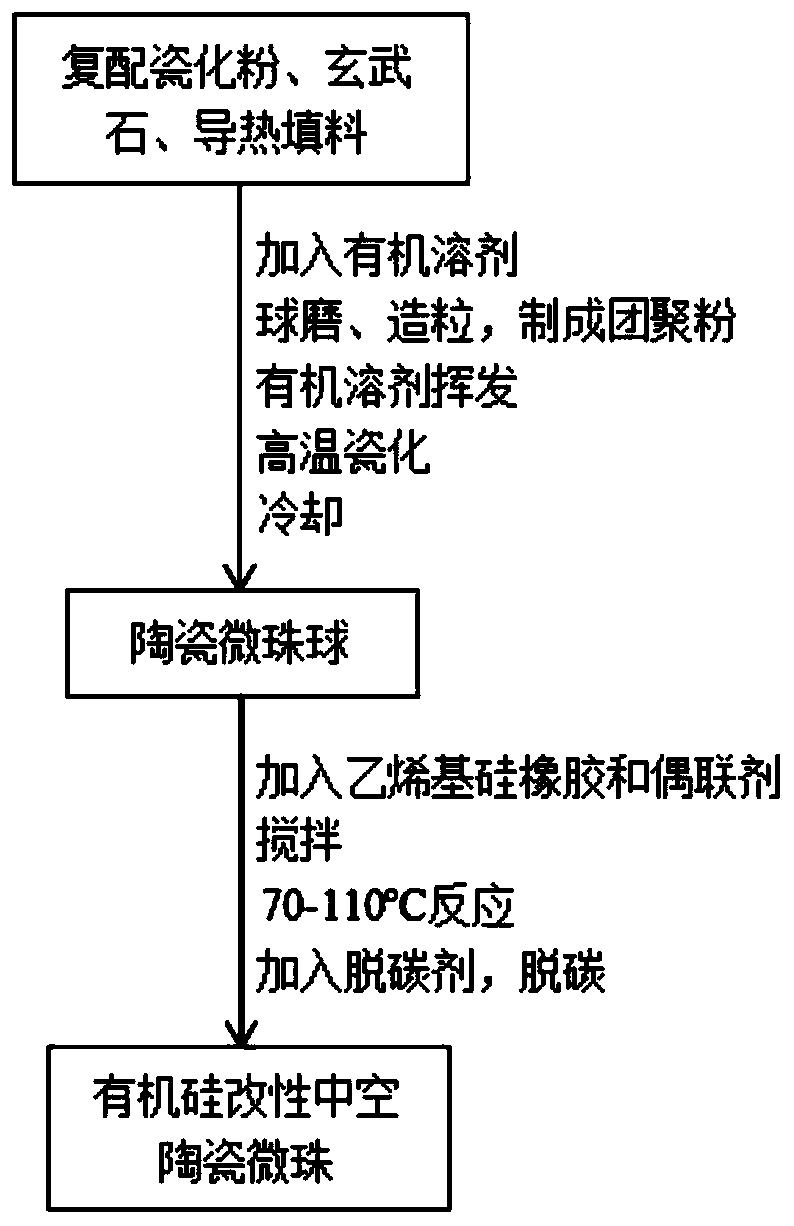

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 Preparation of Silicone Modified Hollow Ceramic Microbeads

[0020] Raw material composition:

[0021] 40 parts of compound porcelain powder (4 parts of low-temperature glass powder, 6 parts of montmorillonite, 6 parts of mica powder, 28 parts of kaolin), 10 parts of decarburizer (boric acid, sodium borate and chloroplatinic acid), 10 parts of isobutyl tri 5 parts of silicon ethoxylate, 20 parts of vinyl silicone rubber, 5 parts of basalt, 5 parts of magnesium oxide, 5 parts of zinc oxide;

[0022] Preparation:

[0023] Take compound porcelain powder, basalt, magnesium oxide, zinc oxide and add a certain amount of acetonitrile, ball mill and granulate to make agglomerated powder of 100-150 μm, volatilize acetonitrile, porcelain at 1200℃ in muffle furnace, cool to room temperature, Create ceramic microspheres, add vinyl silicone rubber and isobutyl triethoxy silicon, stir, react at 70°C for 5 hours, add decarburizer, and decarburize at 400°C in a muffle fu...

Embodiment 2

[0024] Embodiment 2 Preparation of Silicone Modified Hollow Ceramic Microbeads

[0025] Raw material composition:

[0026] 70 parts of compound porcelain powder (3 parts of aluminum hydroxide, 30 parts of montmorillonite, 37 parts of alumina), 15 parts of decarburizer (boric acid, sodium borate and chloroplatinic acid), 15 parts of peroxysilane, ethylene 40 parts of base silicone rubber, 10 parts of basalt, 30 parts of aluminum nitride;

[0027] Preparation:

[0028] Take compound porcelain powder, basalt, aluminum nitride and add a certain amount of pyridine, ball mill and granulate to make agglomerated powder of 100-150μm, pyridine volatilizes, muffle furnace 1200℃ high temperature porcelain, cool to room temperature, and produce ceramics Microbeads, add vinyl silicone rubber and peroxysilane, stir, react at 110°C for 7h, add decarburizer, and decarburize at 400°C in a muffle furnace to obtain organosilicon-modified hollow ceramic microbeads with a yield of 85% %.

Embodiment 3

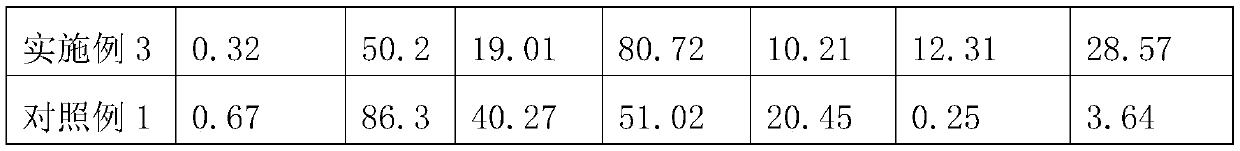

[0029] Example 3 Preparation of Organic Silicon Modified Hollow Ceramic Microbeads

[0030] Raw material composition:

[0031] 52 parts of compound porcelain powder (2 parts of magnesium hydroxide, 20 parts of mica powder, 10 parts of magnesium oxide, 20 parts of aluminum oxide), 13 parts of decarburizing agent (boric acid, sodium borate and chloroplatinic acid), 13 parts of vinyl tri( β-methoxyethoxy) silane 7 parts, vinyl silicone rubber 30 parts, basalt 7 parts, silicon carbide 20 parts;

[0032] Preparation:

[0033] Take compound porcelain powder, basalt, silicon carbide and add a certain amount of organic solvent, ball mill and granulate to make agglomerated powder of 100-150μm, organic solvent volatilizes, muffle furnace 1200℃ high temperature porcelain, cool to room temperature, and produce Ceramic microbeads, add vinyl silicone rubber and vinyl tris(β-methoxyethoxy)silane, stir, react at 90°C for 6h, add decarburizer, decarburize at 400°C in muffle furnace, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com