Novel light impurity deslagging device

A new technology with light impurities, applied in textile and paper making, paper machine, wet end of paper machine, etc., can solve the problems of incomplete separation of slag remover and poor slag removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

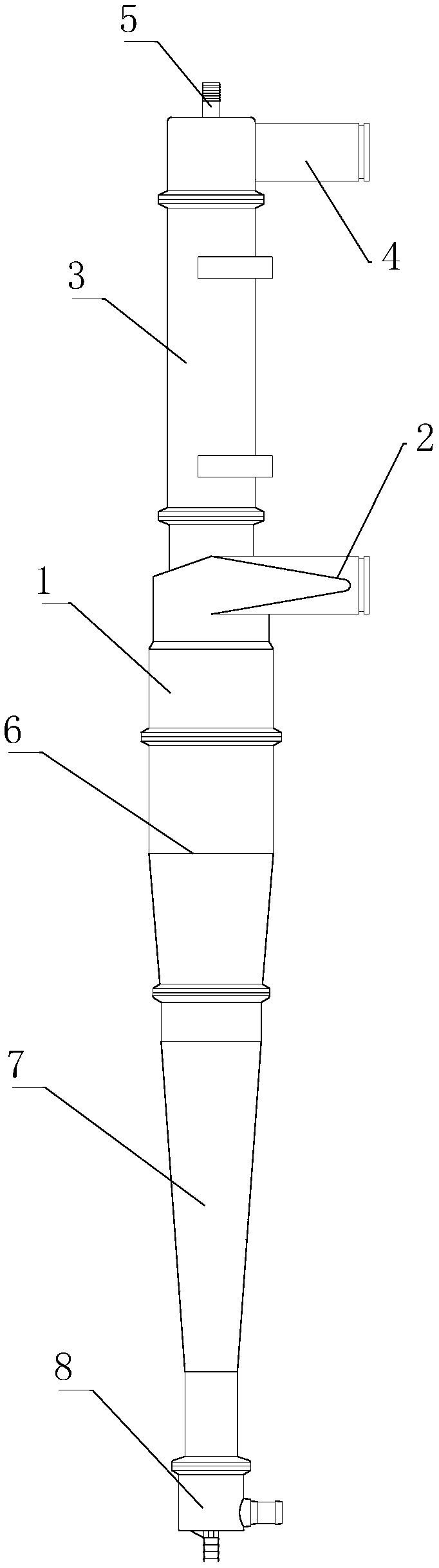

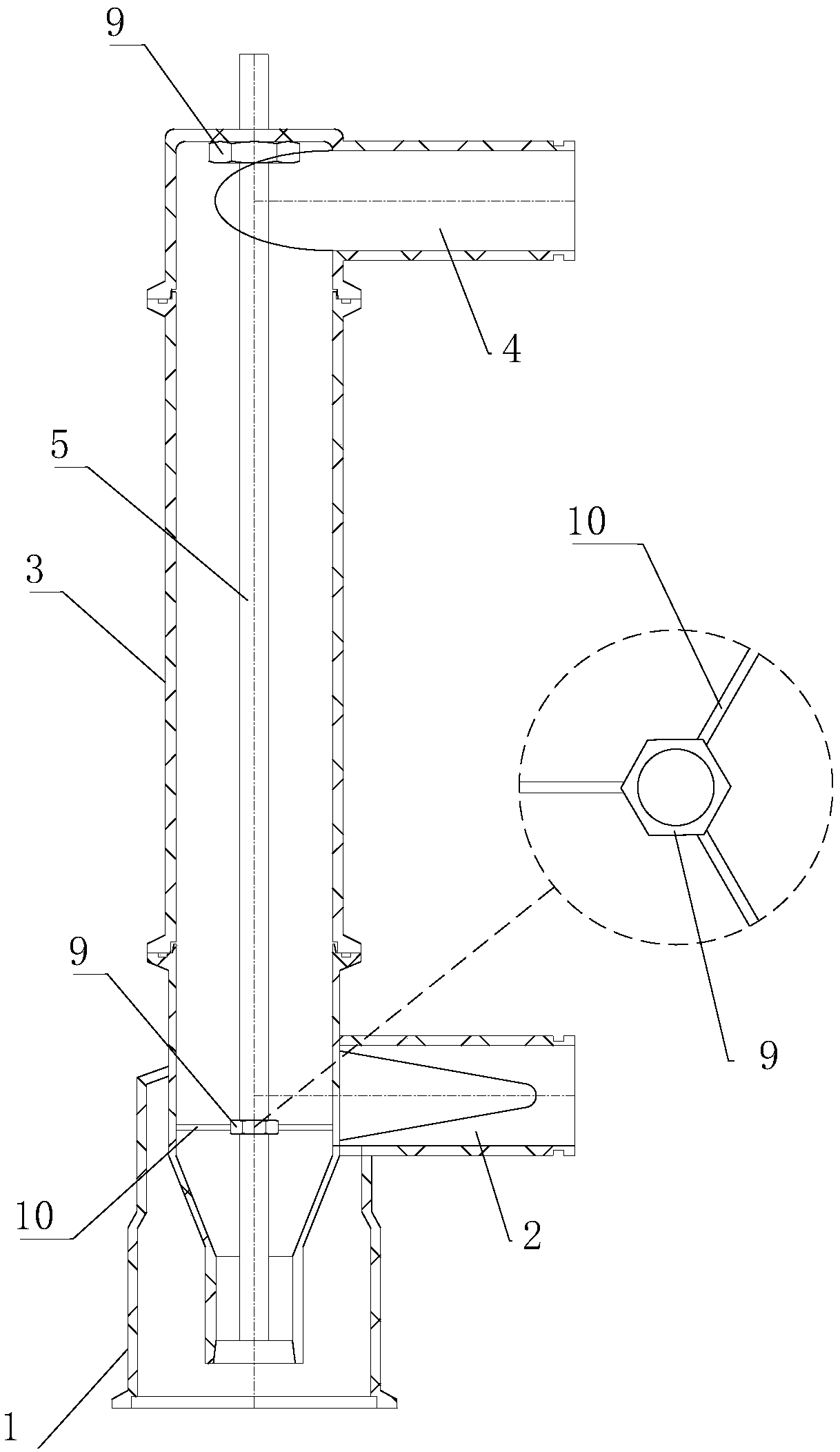

[0023] Such as figure 1 and figure 2 As shown, it is an embodiment of the novel light impurity slag removal device of the present invention. The slag removal device includes a slag removal pipe 1. The slag removal pipe 1 is cylindrical and vertically arranged. The slurry feeding pipe 2 connected with it tangentially.

[0024] The slag removal device also includes a good slurry pipe 3 and a slag removal collection pipe 5 , and the lower end of the slag removal pipe 1 is connected with an intermediate section 6 , a lower cone 7 and a flushing water device 8 . Wherein, the good pulp pipe 3 extends into the inner cavity of the slag removal pipe 1 from top to bottom, and the upper end of the good pulp pipe 3 is provided with a good pulp outlet 4 in the horizontal direction, and the light residue collecting pipe 5 is located at the The inside of the fine pulp pipe 3, the upper end outlet of the light residue collection pipe 5 is higher than the upper end of the good pulp pipe 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com