A kind of method for recovering magnesium fluoride polluted acid by harmless treatment in zinc smelting process

A harmless treatment, magnesium fluorine polluted acid technology, applied to the improvement of process efficiency, etc., can solve the problems of poor solution filtration performance, poor separation effect of zinc and magnesium, occupational health hazards, etc., to improve economic benefits and social benefits, reduce safety and environmental risks, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Take (1) 20,000 grams of zinc sulfite slag produced by a company in Yunnan and dry it for later use. %, silver 0.0037 wt%, iron 1.9 wt%, fluorine 0.021 wt%, chlorine 0.19 wt%; (2) 20 liters of fouling acid, the fouling acid contains 3.9 g / L of acid, 0.81 g / L of fluorine, and 0.36 g of chlorine (3) Take 50 liters of electrolytic waste liquid, which contains 42 g / L of zinc, 40 g / L of magnesium oxide, 143 g / L of sulfuric acid, 0.03 g / L of fluorine, and 0.34 g / L of chlorine; ( 4) Take 2000 grams of zinc calcine, which contains 58.4wt% zinc and 1.8wt% magnesium oxide. (5) Take 500 grams of copper slag, the copper slag contains 5.5wt% zinc, 32.6wt% copper, and 0.022wt% chlorine.

[0078] 1) Slurrying of zinc sulfite slag: take 10 liters of industrial water and 20 liters of electrolytic waste liquid, add 10,000 grams of zinc sulfite slag for slurrying, slurry for 10 minutes, stir and slurp evenly and then stand by for use;

[0079]2) For one acid leaching, take 5 liters of p...

Embodiment 2

[0094] Take (1) 20,000 grams of zinc sulfite slag produced by a company in Yunnan and dry it for use. %, silver 0.0051wt%, iron 3.2wt%, fluorine 0.034wt%, chlorine 0.22wt%; (2) 20 liters of fouling acid, the fouling acid contains 7.4 grams per liter of acid, 4.8 grams per liter of fluorine, and 2.1 grams of chlorine (3) Take 50 liters of electrolytic waste liquid, which contains 44 g / L of zinc, 46 g / L of magnesium oxide, 157 g / L of sulfuric acid, 0.028 g / L of fluorine, and 0.34 g / L of chlorine; ( 4) Take 2000 grams of zinc calcined sand, the zinc calcined sand contains 56.3wt% zinc and 1.9wt% magnesium oxide. (5) Take 500 grams of copper slag. The copper slag contains 7.8 wt % of zinc, 35.3 wt % of copper, and 0.024 wt % of chlorine.

[0095] 1) Slurrying of zinc sulfite slag: take 5 liters of industrial water and 30 liters of electrolytic waste liquid, add 11,000 grams of zinc sulfite slag for slurrying, slurry for 10 minutes, stir and slurp evenly and then stand by for use;...

Embodiment 3

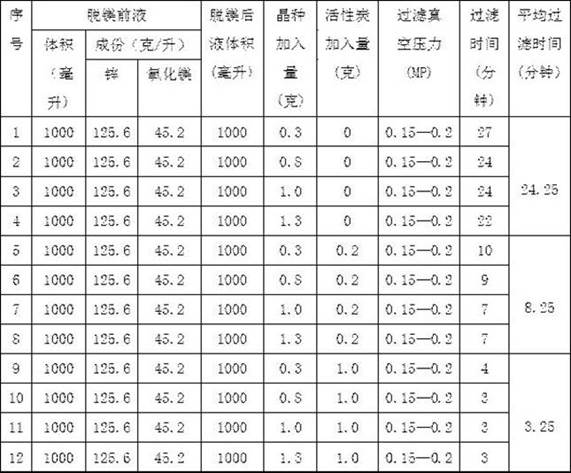

[0111] The difference between this embodiment and the above-mentioned Embodiments 1 and 2 is that, according to the amount of crystal seeds added and whether to add activated carbon, and the amount of activated carbon to be compared, a comparison table of the influence of these factors on the filtration rate is obtained, see Table 1.

[0112] Table 1 Comparison of the effect of activated carbon addition on the filtration rate of the demagnesium solution

[0113]

[0114] It can be seen from Table 1 that although the filtration speed is improved to a certain extent after adding the seed crystal, the effect is not ideal. After adding an appropriate amount of activated carbon as a modifier, the filtration effect is very good, and the filtration speed increases with the appropriate increase of the amount of activated carbon added.

[0115] In a word, it can be seen from the examples that by adding an appropriate amount of activated carbon, the problems that high zinc-containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com