Patents

Literature

32results about How to "Reduce safety and environmental risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

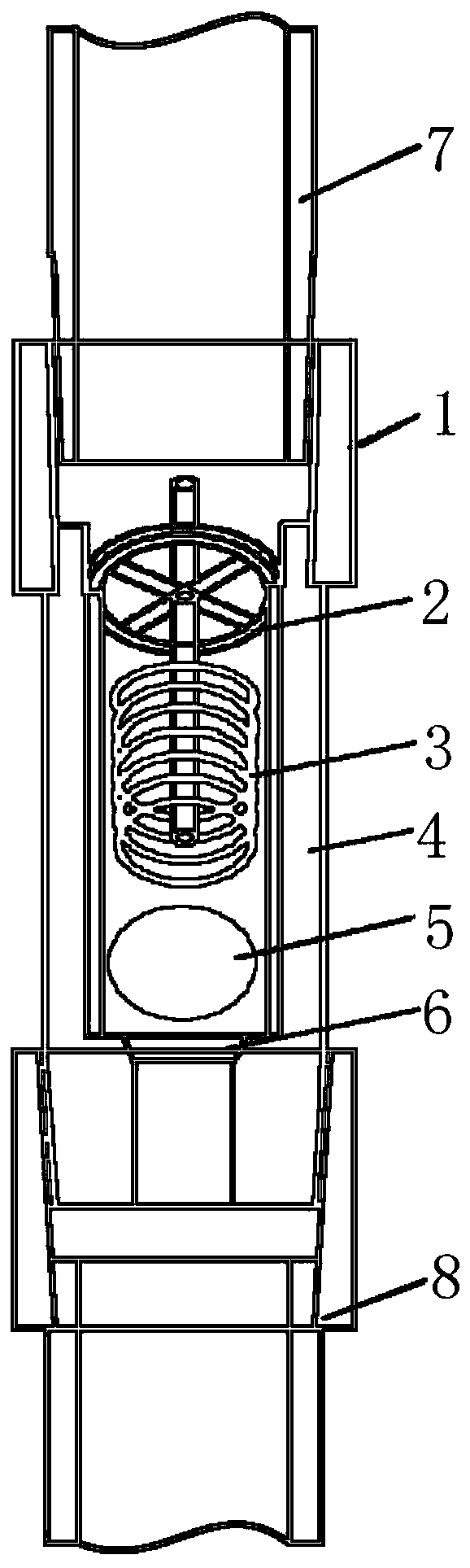

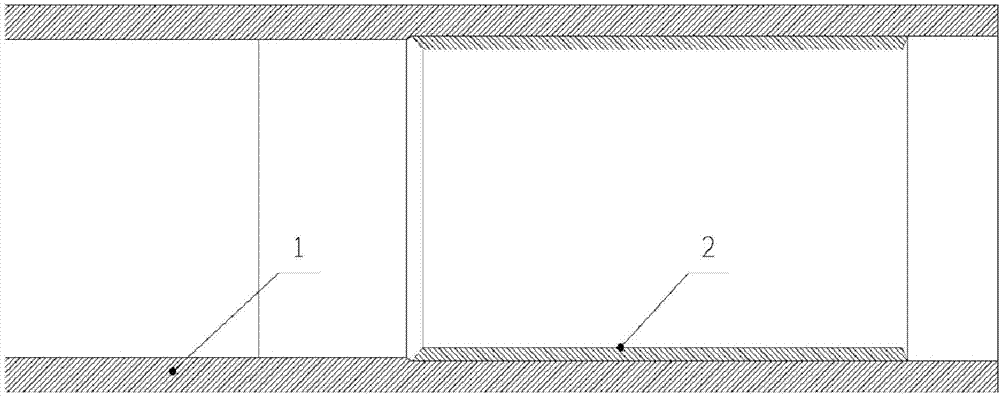

Suspended type oil submersible direct drive screw pump oil extraction device

InactiveCN105485028AShorten the lengthSimple structurePump componentsFluid removalEngineeringUltimate tensile strength

The invention provides a suspended type oil submersible direct drive screw pump oil extraction device which comprises a screw pump and an oil submersible motor, wherein the screw pump is fixed to the oil submersible motor through welding; the screw of the screw pump stretches into the oil submersible motor; the oil submersible motor comprises a motor shell, a motor stator and a motor rotor; the upper end of the motor shell is connected with a steel wire rope; the motor stator and the motor rotor are arranged in the motor shell; and the interior of the motor rotor is connected with a bushing through a connecting piece. According to the device, an oil submersible motor-screw pump integrated device is adopted, the structure is simpler, the cost is lower, and the problems that during the downhole process, a cable is liable to abrasion, a drilling tool is liable to blocking, the rountrip procedure is complex, the efficiency is relatively low, and the labor intensity is relatively high are solved.

Owner:PETROCHINA CO LTD

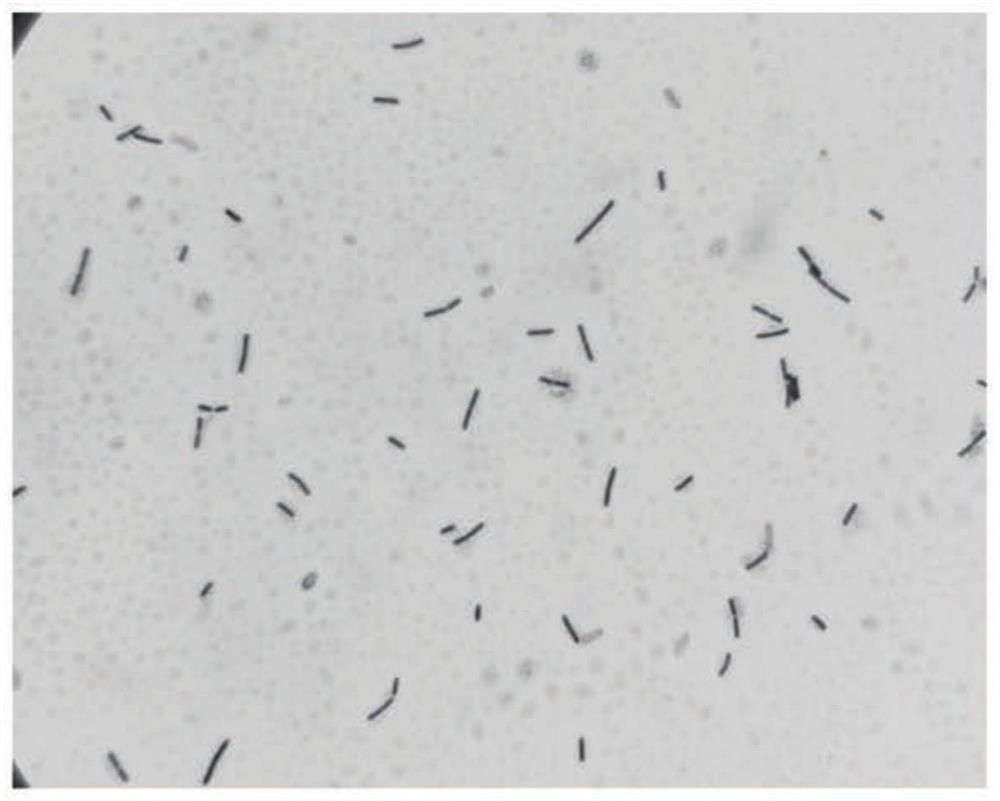

Water-based drilling soft solid waste recycling treatment and utilization technology

InactiveCN110449446AHigh organic contentEffective degradation and removalSolid waste disposalContaminated soil reclamationWater basedEngineering

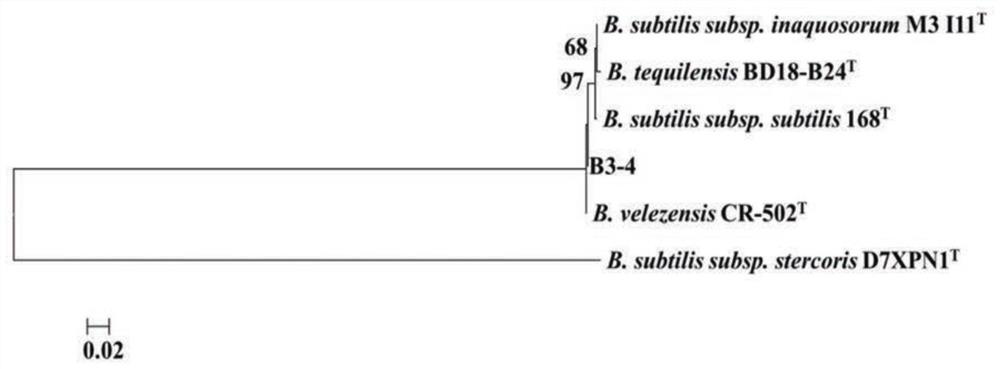

The invention discloses a water-based drilling soft solid waste recycling treatment and utilization technology. The water-based drilling soft solid waste recycling treatment and utilization technologycomprises the steps that drilling soft solid waste is mixed evenly, a microorganism strain with a decomposing effect is inoculated at the proportion of 0.5%-1% by weight, and even mixing is carried out; then, a microorganism nutrient of 0.5%-2% of the solid waste by weight is added and mixed evenly, and the mixture is evenly mixed with soil with the water content of 15%-20%, wherein the mixing proportion of the solid waste and the soil is 1:(0.5-3) by weight; and the treated mixture is stacked, plants are planted or grass seeds are cast in the mixture, and a microorganism-soil-plant united system is used for decomposing treatment of organic pollutants in the drilling soft solid waste. By means of the water-based drilling soft solid waste recycling treatment and utilization technology, COD, Oil and other substances in the drilling work soft solid waste can be effectively decomposed and removed, part of the organic pollutants are decomposed into simple inorganic substances, and part ofthe organic pollutants are decomposed into humus, so that pollutants in the solid waste are removed, and the purposes of harmlessness and recycling utilization of the solid waste are achieved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Water-based drilling fluid system solid waste recycle disposal and utilization process

InactiveCN110340116AReduce occupancyReduce transfer volumeSolid waste disposalContaminated soil reclamationWater basedWell drilling

The invention discloses a water-based drilling fluid system solid waste recycle disposal and utilization process. The water-based drilling fluid system solid waste recycle disposal and utilization process includes: mixing polymer drilling fluid system drilling solid wastes uniformly, inoculating microorganism strains having degradation function according to a weight ratio of 0.1%-0.3% and uniformly mixing the microorganism stains with the polymer drilling fluid system drilling solid wastes, and then uniformly mixing the polymer drilling fluid system drilling solid wastes doped with the microorganism stains with soil containing 15%-20% of water, setting a mixing weight ratio of the drilling solid wastes and the soil as 1:0.2-0.5, stacking mixtures to be disposed, and using a microorganism-soil joint system for performing degradation disposal on organic polymers in the drilling solid wastes. The water-based drilling fluid system solid waste recycle disposal and utilization process achieves bioremediation disposal for the drilling solid wastes, obtains disposal materials which can be used as soil for completion well field second ploughing, achieves recycle disposal and utilization, and then achieves disposal recycling for different categories of the drilling water-based solid wastes.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Classification treatment and utilization method for water-based solid waste of petroleum and natural gas exploration drilling

InactiveCN111360029ARealize classified disposal and utilizationReduce the amount of solid waste disposal and utilizationSolid waste disposalTransportation and packagingBrickWell drilling

The invention provides a classification treatment and utilization method for water-based solid waste of petroleum and natural gas exploration drilling. According to the method, for the situation thatthe geological structure is complicated and the well depth is 4,000 m or above, drilling solid waste of a polymer drilling fluid system and drilling solid waste of a sulfonated drilling fluid system are adopted in sequence. The classification treatment and utilization method comprises the steps that correspondingly generated drilling solid waste is classified and collected according to different drilling fluid systems used during drilling, wherein the drilling solid waste comprises clean water drilling solid waste, polymer drilling solid waste and sulfonated drilling solid waste. The treatmentand utilization method comprises the following steps that the clean water drilling solid waste is directly transferred to a stacking field and stacked to be used as a filler or a building material; biological treatment resource soil utilization is conducted on the polymer drilling solid waste in situ; and reduction and liquid exhaustion are conducted on the sulfonated drilling solid waste, and then the treated drilling solid waste is transferred to a brick making factory to serve as a brick making raw material. The classification treatment and utilization method has the beneficial effects that the water-based solid waste can be classified and collected and classified and treated and utilized, and the transfer and disposal cost is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Polymer suspension emulsion for fracturing fluid and preparation method thereof

PendingCN112175208APromote dissolutionGood salt resistanceDrilling compositionAmmonium sulfateMineral oil

The invention discloses a polymer suspension emulsion for fracturing fluid. The polymer suspension emulsion comprises the following components in parts by weight: 350-450 parts of mineral oil, 16-20 parts of a suspending agent, 350-550 parts of polymer powder, 70-80 parts of inorganic potassium salt, 75-100 parts of alkyl ether ammonium sulfate, 35-60 parts of a demulsifying agent and 10 parts ofa wetting agent. The preparation method of the suspension emulsion comprises the following steps: (1) adding mineral oil into a production kettle, and starting stirring at the stirring frequency of 25Hz; (2) sequentially adding the suspending agent, the polymer powder and the sylvite into a production kettle; (3) adjusting the stirring frequency to 35Hz, opening a circulating valve of the production kettle, starting a primary circulating pump, and circularly stirring the materials for 30min; and (4) adding alkyl ether ammonium sulfate, the demulsifying agent and the wetting agent, closing theprimary circulating pump, starting the secondary circulating pump, and continuously and circularly stirring for 30 minutes to obtain the polymer suspension emulsion for the fracturing fluid. The suspension emulsion prepared by the invention has the advantages of rapid dissolution, good salt resistance, good stability and low cost, and meets the technical requirements of continuous blending large-displacement hydraulic fracturing construction.

Owner:江西富诚生态环境科技集团有限公司

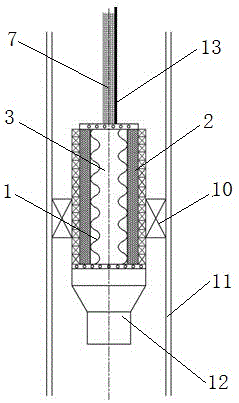

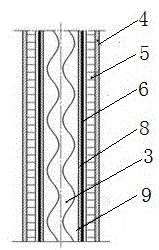

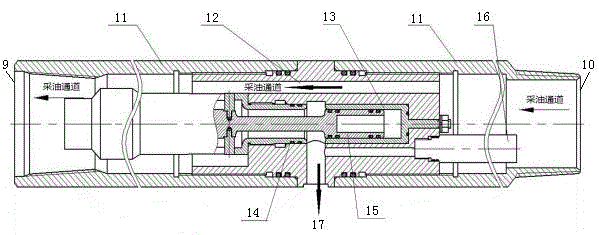

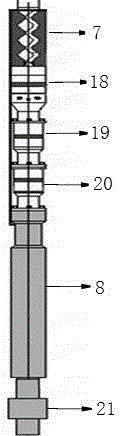

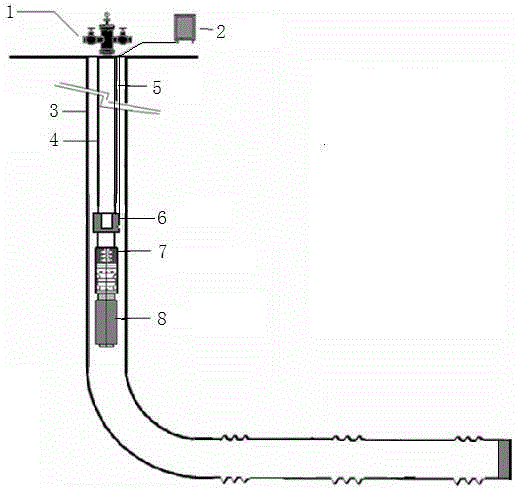

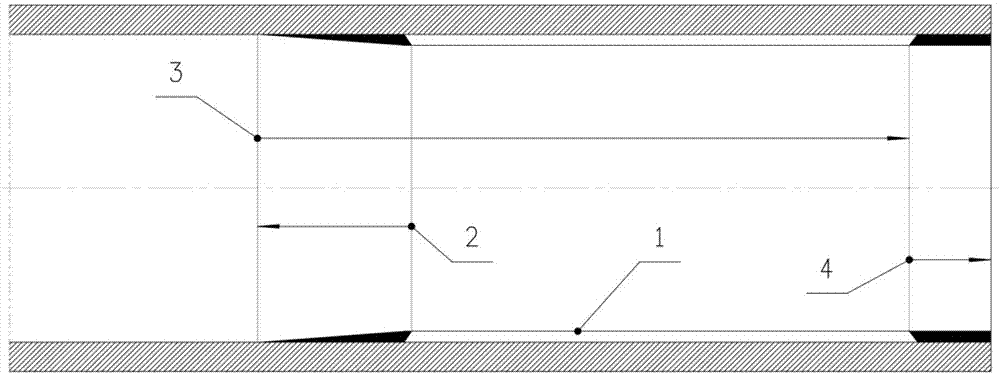

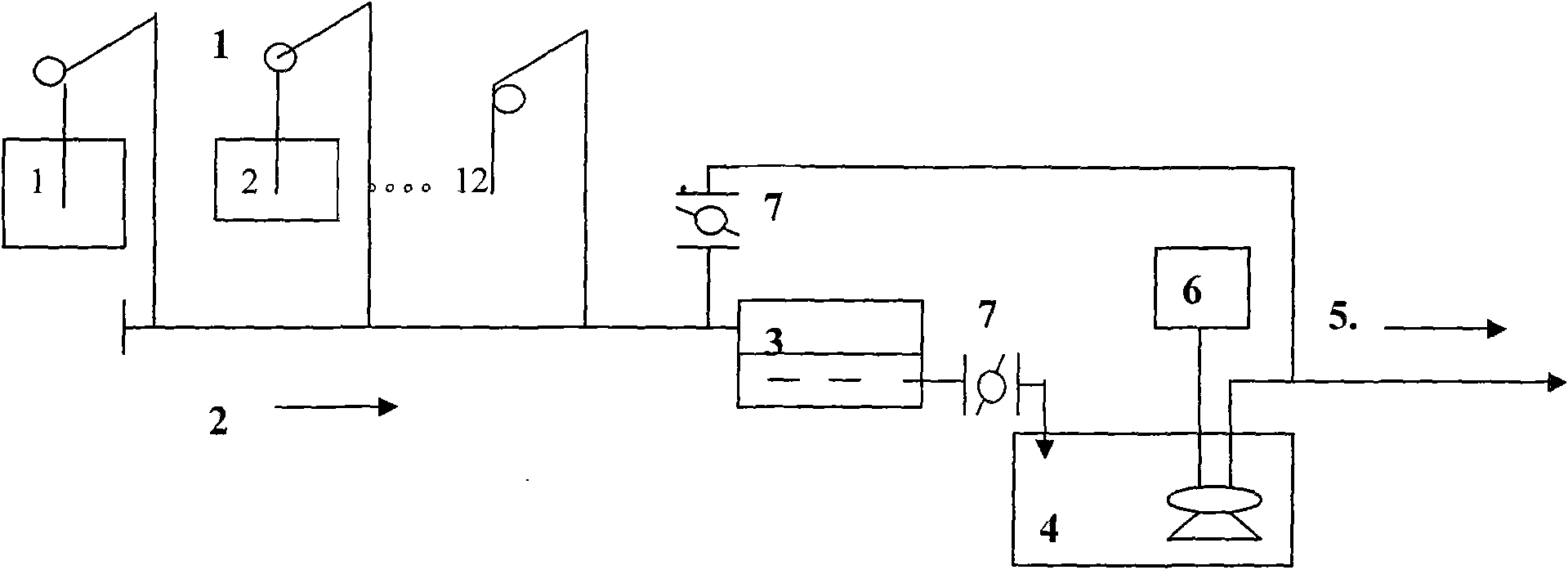

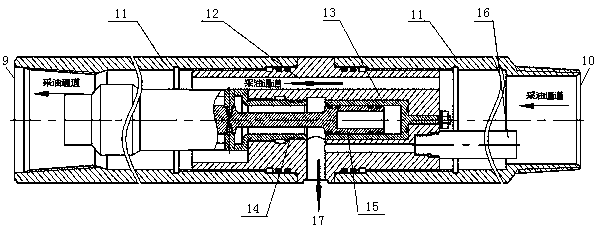

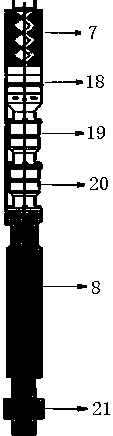

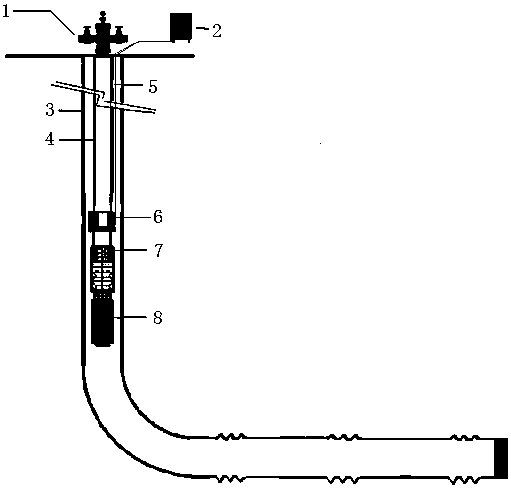

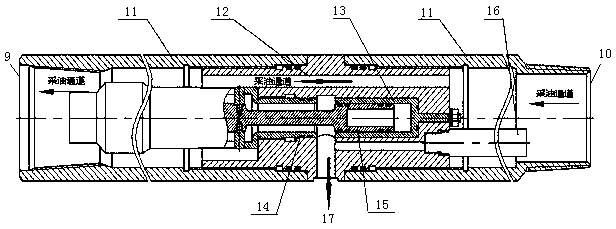

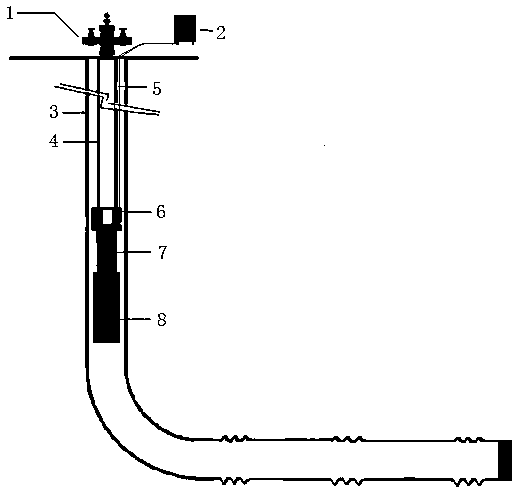

Huff-and-puff oil production device with submersible directly-driven screw pump

ActiveCN105422053AOptimize work processImprove construction efficiencyFluid removalWell/borehole valve arrangementsMarine engineeringElectric machinery

The invention provides a huff-and-puff oil production device with a submersible directly-driven screw pump. The huff-and-puff oil production device comprises an underground automatic water injection switch for realizing water injection and oil production channel switching and a submersible directly-driven screw pump, wherein a liquid outlet in the upper end of the underground automatic water injection switch is connected with an oil pipe, and a liquid inlet in the lower end of the underground automatic water injection switch is connected with an oil outlet in the upper end of the submersible directly-driven screw pump through the oil pipe; the submersible directly-driven screw pump comprises a screw pump, a flexible shaft, an upper protect tor, a lower protector, a submersible motor and a centralizer which are non-coaxially connected from top to bottom; the upper end of the screw pump is connected with the lower end of the underground automatic water injection switch; and the screw pump and the submersible motor are respectively electrically connected to a submersible cable outside a wellhead. The huff-and-puff oil production device is free of repeatedly tripping and has the characteristics of simple and convenient operation flow, high construction efficiency, safety, environment friendliness, low risk and the like; and due to the adoption of the lifting way, the huff-and-puff oil production device has the characteristics of low rotating speed and large torque and is suitable for a well with low liquid quantity, the eccentric wear of pipe poles is eliminated, the maintenance-free period of an oil well is prolonged, and the economic benefit can be effectively increased.

Owner:PETROCHINA CO LTD

Preparation method of well site environment-friendly toilet degradation product and method for treating water-based solid waste

PendingCN112479391AReduce transshipmentReduce usageSludge treatment by de-watering/drying/thickeningSolid waste disposalMicroorganismFirewood

The invention provides a preparation method of a well site environment-friendly toilet degradation product and a method for treating water-based solid waste, and the well site environment-friendly toilet degradation product cooperative biological treatment method for water-based drilling solid waste comprises the following steps of: uniformly mixing to-be-treated water-based drilling solid waste,inoculating a microbial degradation strain with a degradation effect according to a weight ratio of 0.1-0.3%, and fully and uniformly mixing the substances; adding an environment-friendly toilet degradation product which accounts for 0.5-1wt% of the amount of the to-be-treated water-based drilling solid waste, and fully and uniformly mixing the environment-friendly toilet degradation product and the water-based drilling solid waste; adding fine fresh soil of which the amount is 0.1-1 time that of the to-be-treated solid waste, uniformly mixing the substances, and performing stacking; coveringthe surface of the treated object with fresh soil with a certain thickness, and sowing and planting ornamental or firewood plants on the treated object, thus forming a well site solid waste-microorganism-plant combined degradation system. The method has the advantages that cooperative treatment and resource soil utilization of the drilling living solid waste and the drilling water-based solid waste can be achieved, the purposes of double emission reduction and utilization are achieved, the reduction, harmlessness and resource principle of solid waste disposal is achieved, and the outward transfer and disposal amount and cost are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

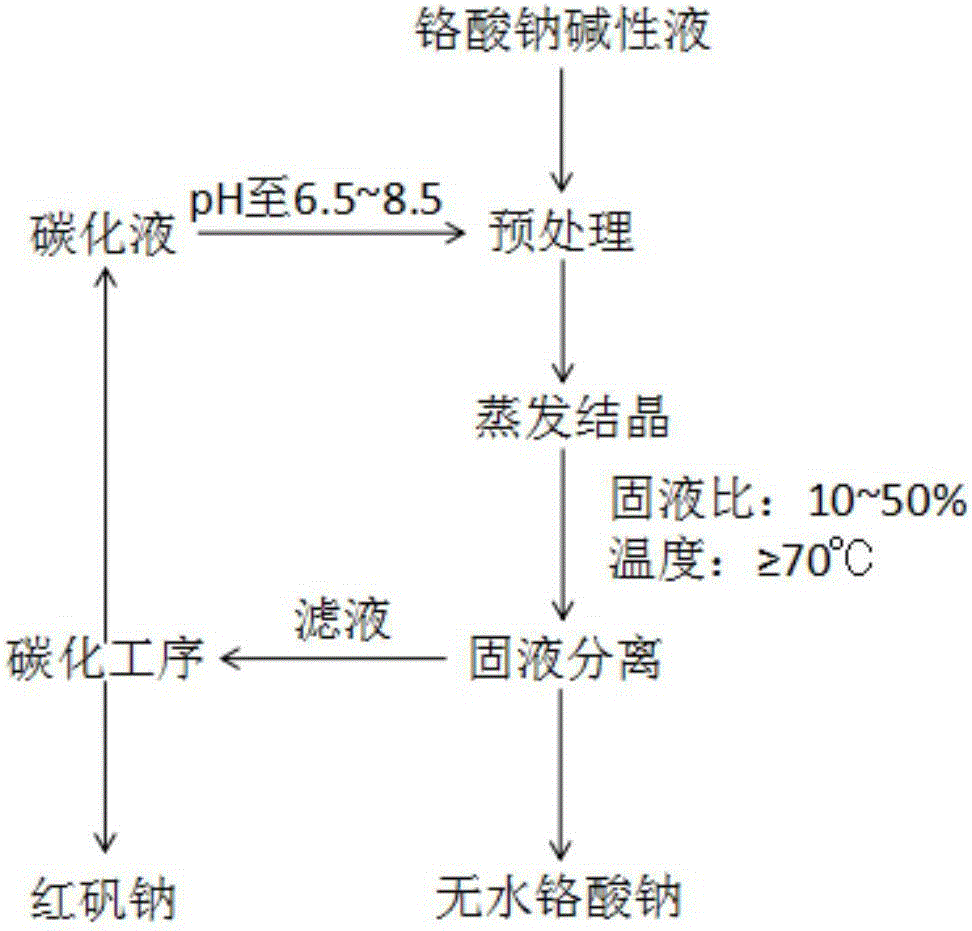

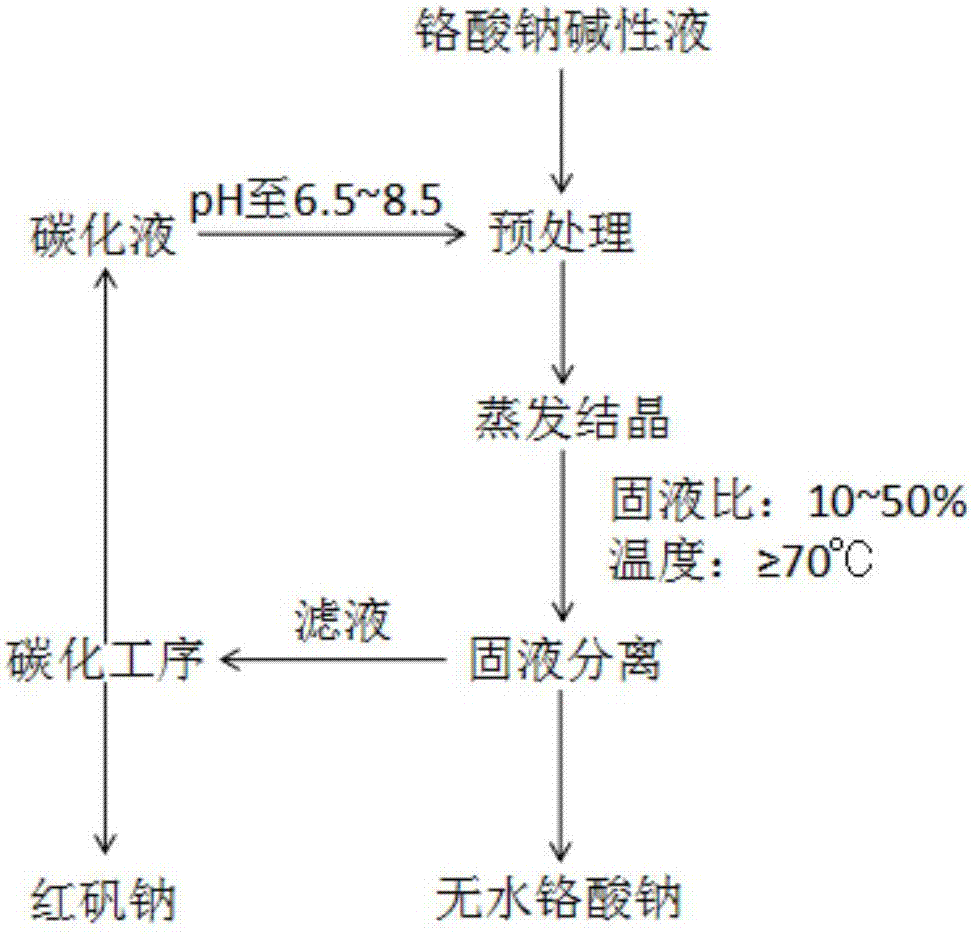

Method for preparing anhydrous sodium chromate

ActiveCN106629849AImprove qualitySolve moisture absorptionChromates/bichromatesBulk chemical productionProduction lineLiquid ratio

The present invention discloses a method for preparing anhydrous sodium chromate. The method comprises the steps of mixing a sodium chromate alkali solution with a carbonating solution in proportion of (1:1) to (8:1), and then, adjusting the pH to 6.5-8.5 to obtain a pretreatment solution of sodium chromate; placing the pretreatment solution of sodium chromate in an evaporation crystallizer for vacuum evaporation at the temperature of 80 DEG C to 120 DEG C under the pressure of 0.01 MPa to 0.09 MPa; and when the solid-to-liquid ratio reaches 10%-50% through vacuum evaporation, performing solid-liquid separation at the temperature of 70 DEG C or above to obtain anhydrous sodium chromate and a filtrate. Based on the technology characteristics of sodium dichromate preparation by a carbonation method, high-quality anhydrous sodium chromate is successfully prepared by the method disclosed by the invention, with the main content being equal to or greater than 99.5% and the content of all impurities such as sulfate being less than 0.001%; moreover, the product does not absorb moisture or cake even if stored for a long term, and has good fluidity. The problems of sodium chromate tetrahydrate on easy moisture absorption, caking and poor fluidity are successfully solved. The method also brings into play the superiority of a production process of preparing sodium dichromate from a chromium salt by the carbonation method, so that two high-quality chemical products can be produced on one production line.

Owner:SICHUAN YINHE CHEM

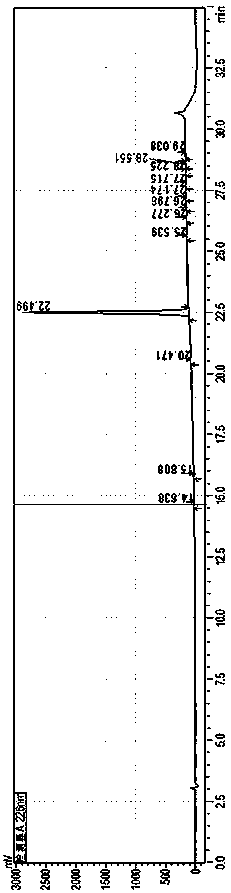

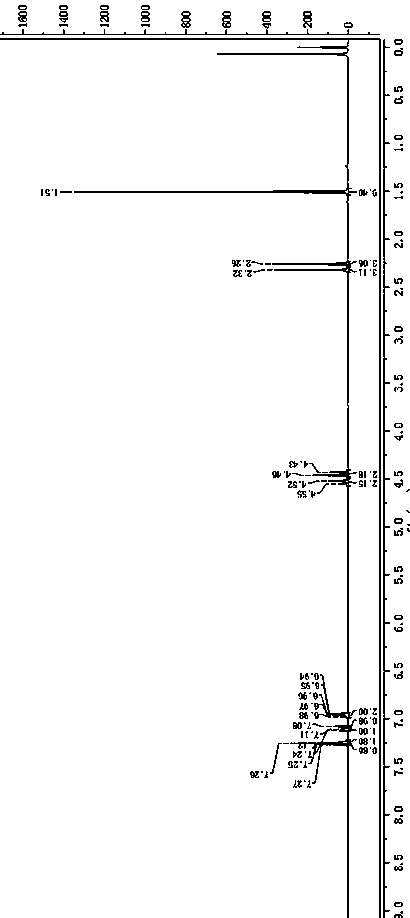

Preparation method of votistine hydrobromide midbody

InactiveCN107915685AQuality improvementShorten the production cycleOrganic chemistryIminodiacetic acidHydrobromide

The invention discloses a preparation method of votistine hydrobromide midbody. The preparation method includes steps of using a midbody B or 2-(2, 4-dimethyl phenyl sulfenyl) aniline as a raw material, and reacting with N-Boc-iminodiacetic acid in non-proton solvent under the effect of condensating agent; after completing reaction, performing concentration, extraction, concentration and refiningto obtain the 1-tert-butoxy carbonyl-4-[2-(2, 4-dimethyl phenyl sulfenyl) phenyl]-3, 5-dioxo piperazine with high purity and high yield, or a midbody C namely. The whole synthetic process has the advantages of low raw material cost, low solvent toxicity, short reaction time, high product yield and good quality, and is suitable for industrial production.

Owner:CHONGQING ZEN PHARMACEUTICAL CO LTD

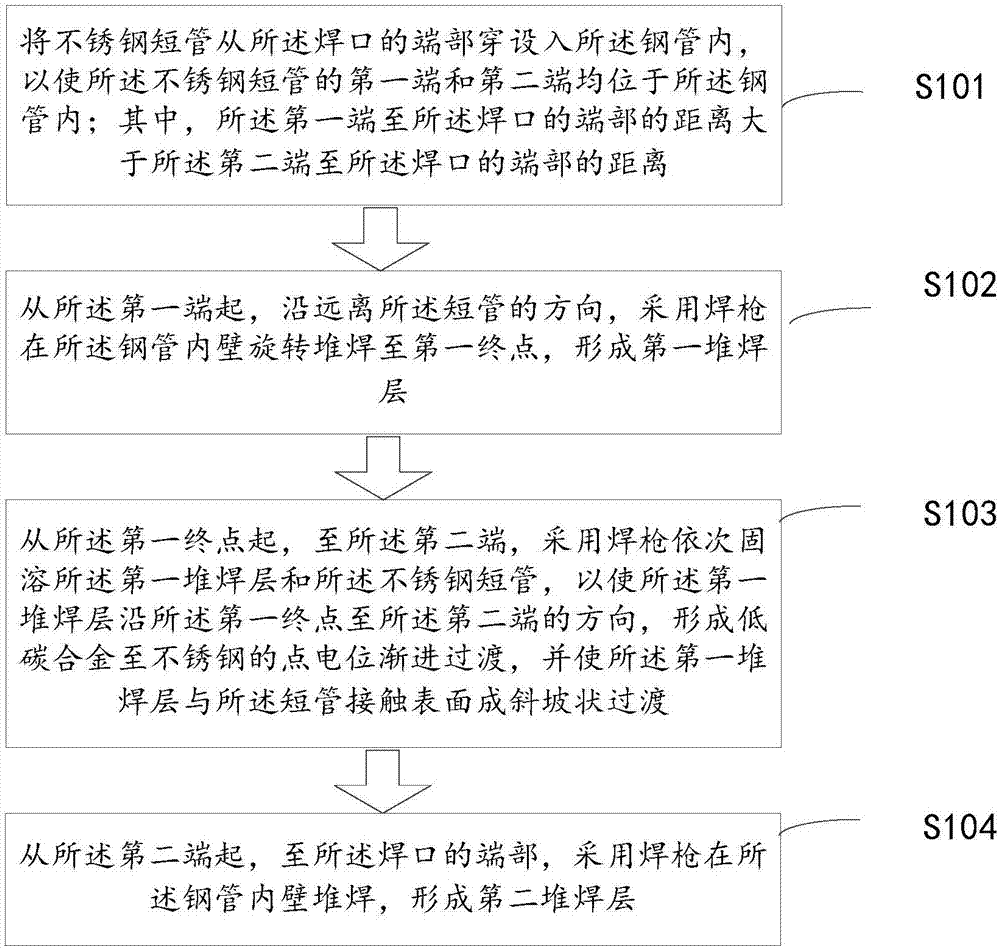

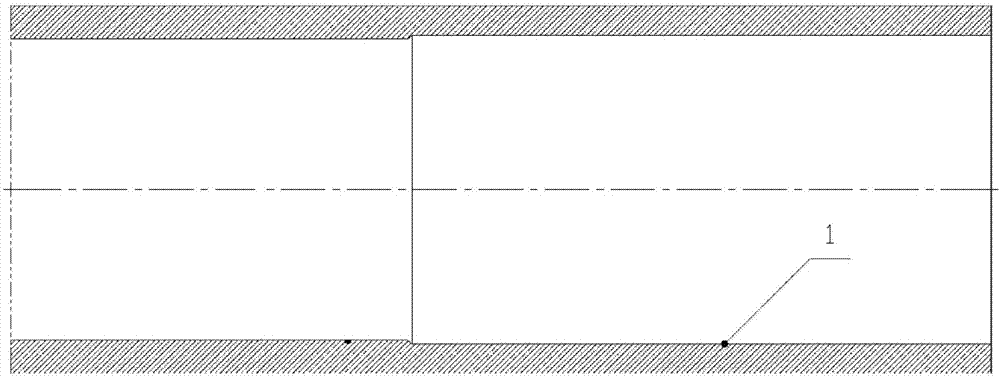

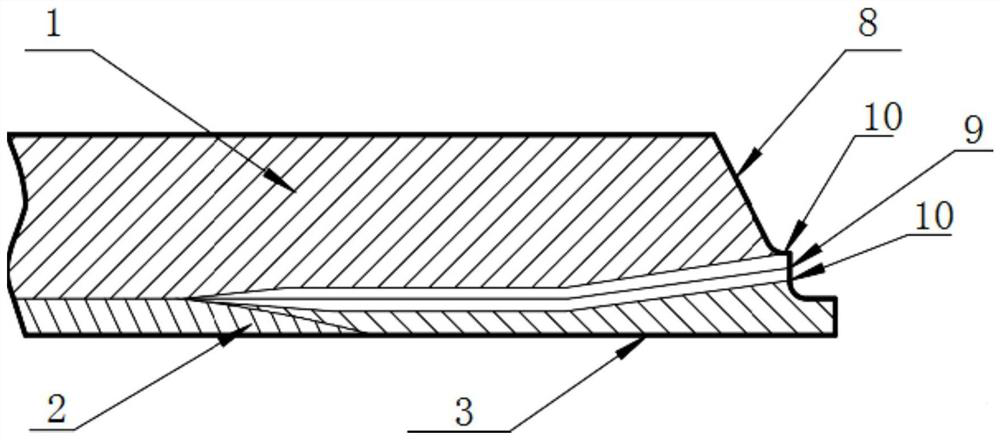

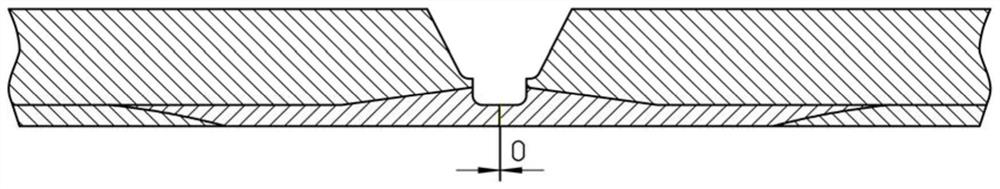

Solid solution transition close potential stainless steel bead welding method for pre-repairing of steel pipeline welded junction

InactiveCN107052519ASolve the technical problems of anti-corrosion fillingExtend your lifeArc welding apparatusMetal working apparatusSolid solutionSteel pipeline

The invention discloses a solid solution transition close potential stainless steel bead welding method for a pre-repairing of a steel pipeline welded junction. The method is used for bead welding of stainless steel on the inner wall at the end of a low carbon steel pipe, in particular to the solid solution transition close potential stainless steel bead welding method for pre-repairing of the steel pipeline welded junction. The method differs from other stainless steel bead welding methods for steel pipeline welded junction pre-repairing and is the solid solution transition close potential stainless steel bead welding method with the premise that good welding performance and inner corrosion prevention performance of the steel pipeline welded junction are guaranteed and corrosion of a bead welding bimetallic cell on the inner wall of the steel pipeline welded junction is prevented. The method is the key technology guaranteeing continuousness of a corrosion prevention layer of the inner wall of a steel pipeline and belongs to one of the main contents of the steel pipeline DGR integrated corrosion prevention technology.

Owner:CNPC RES INST OF ENG TECH +1

Sand-out returning fluid stop valve for oil well and application method of stop valve

PendingCN110671064AImprove the efficiency of sand washing operationsImprove safety and environmental protection management levelFlushingPlate pressurePressure balance

The invention belongs to the technical field of tools for the oil and gas field and particularly provides a sand-out returning fluid stop valve for an oil well and an application method of the stop valve. The stop valve comprises an upper connector, a baffle, a pressure balance spring, a stop valve body, a setting ball, a ball seat, an upper oil pipe male buckle and a lower oil pipe female buckle.The problems are solved that in the prior art, during sand-out of the oil well, in the process of replacing a joint, there is still full of water in the well field, the requirement of the environmental protection act cannot be met, in the reverse-circulation sand-out process, the flow direction of pumped fluid is identical to that of returning fluid during sand-out and joint replacement, a checkvalve cannot be installed on an in-well pipe column, if the project is complex in the sand-out process, forward sand-out and reverse sand-out are needed, and installation of the check valve cannot meet the construction demand. According to the stop valve, overflowing of the returning fluid in the sand-out operation joint replacement process can be effectively blocked, the environmental pollution is avoided, site construction is effectively guided, the sand-out operation efficiency of a common oil pipe is improved, and the safety and environment protection risks are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Probenazole production process

ActiveCN101712677BReduce pollutionMake up for the lack ofOrganic chemistryPhosphorus pentasulfideEthyl acetate

Owner:JIANGSU NOON CROP SCI CO LTD

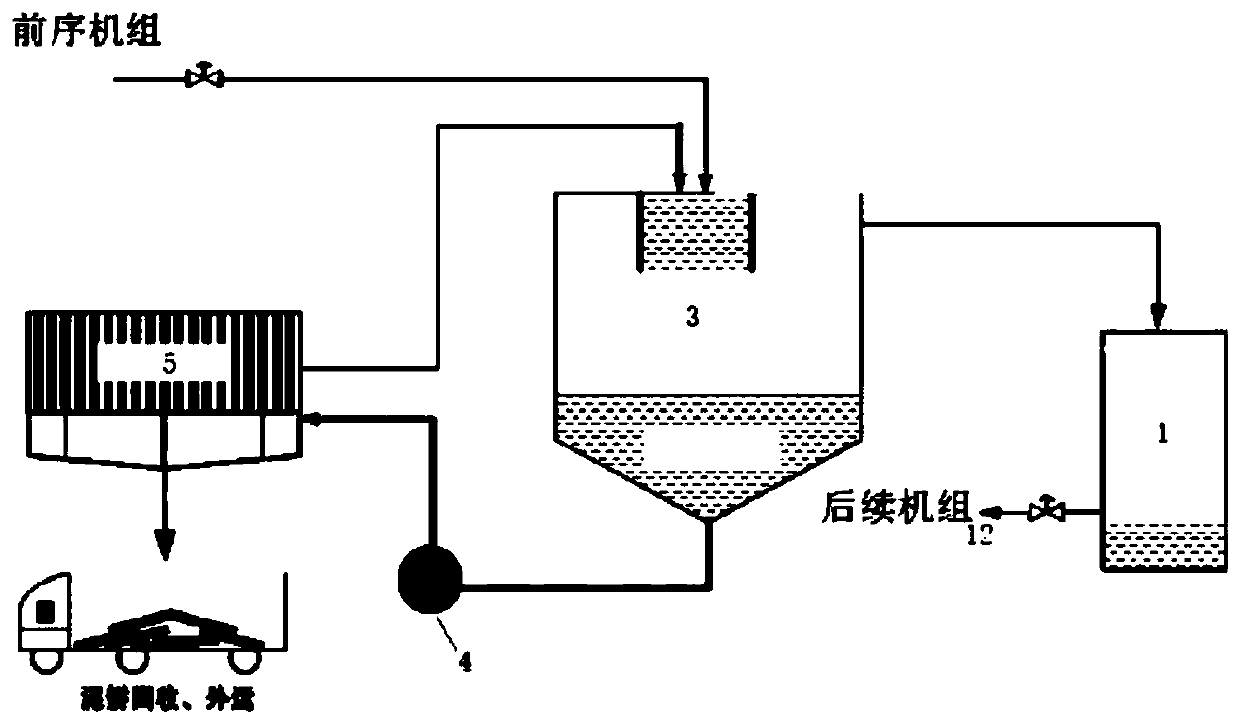

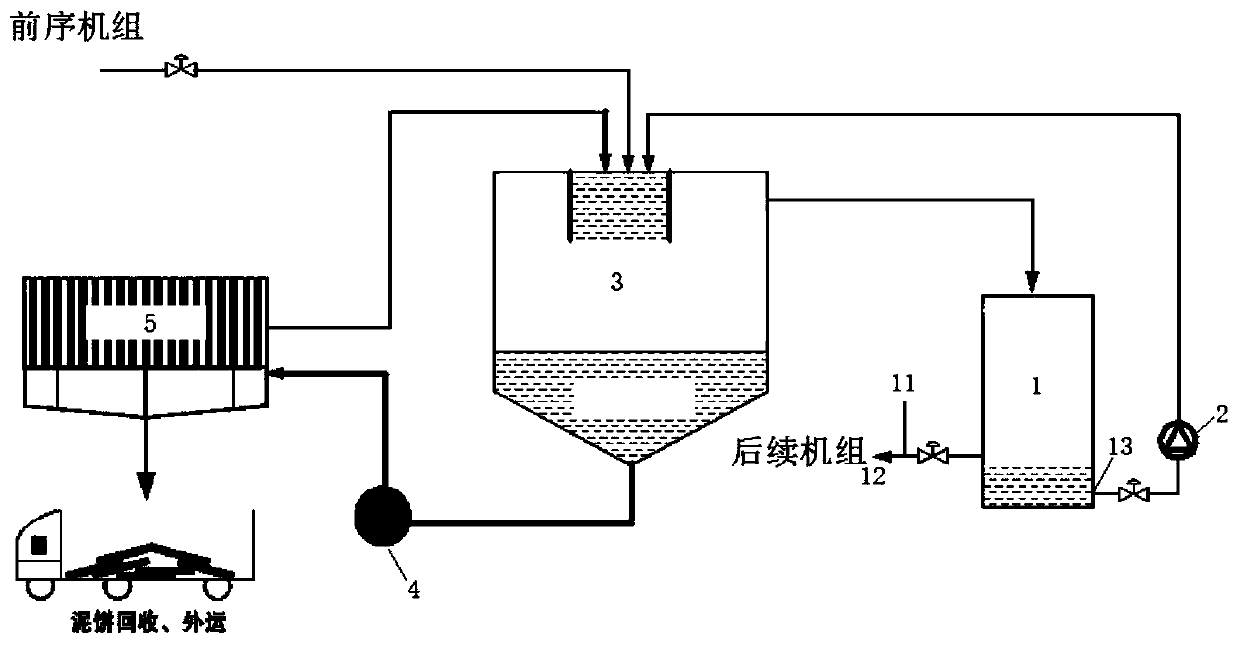

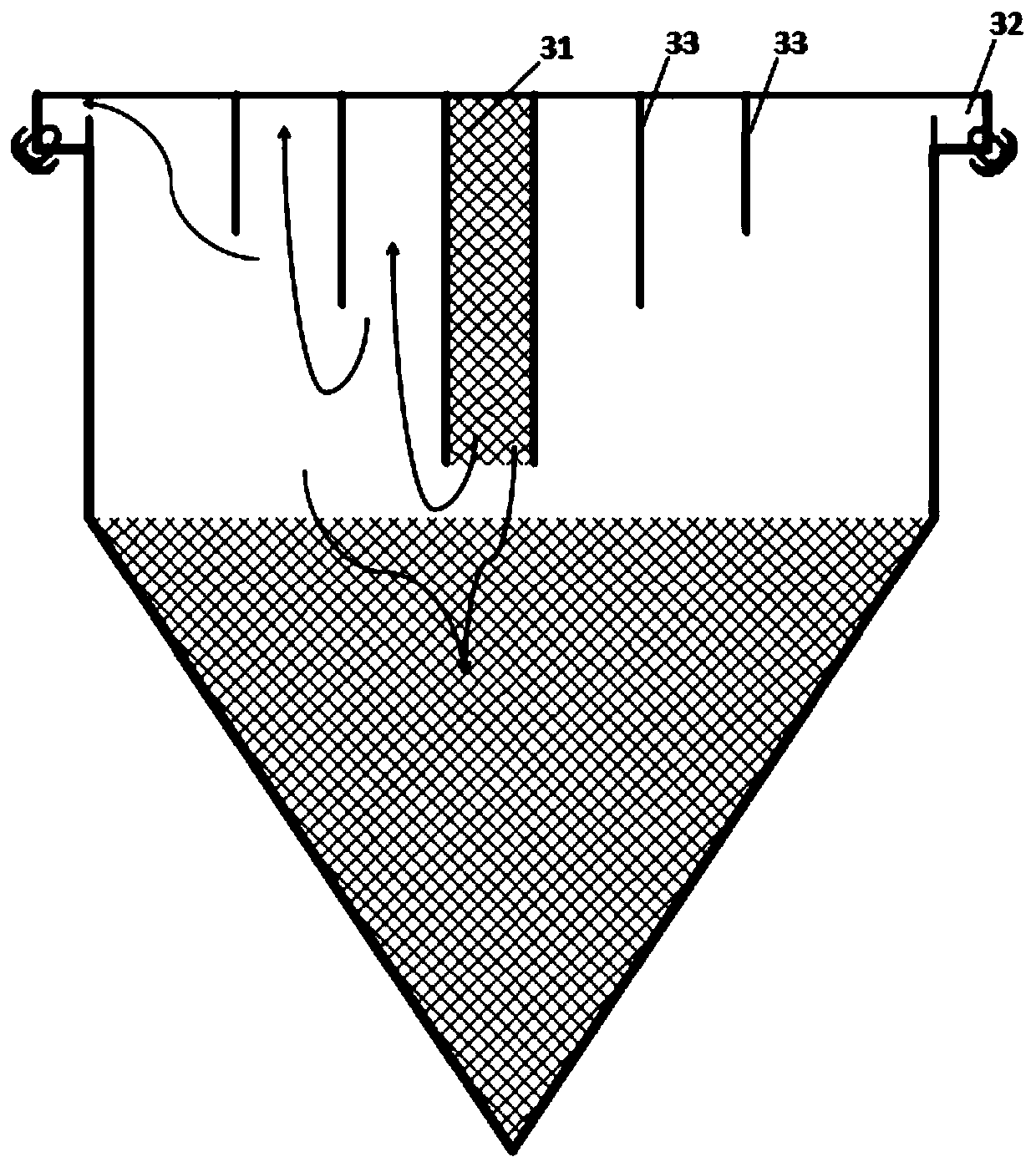

System for recovering cold-rolled acid regeneration acid-containing mud slurry, and method for recovering cold-rolled acid

InactiveCN111001196AReduce safety and environmental risksLow running costSludge treatmentSettling tanks feed/dischargeDigestion TreatmentMud systems

The invention provides a system for recovering cold-rolled acid regeneration acid-containing mud slurry, and a method for recovering a cold-rolled acid. In the system, acid-containing mud slurry in aneffluent is observed through an observation opening in the side surface of a desilicication liquid storage tank; a dirt discharge port is formed in the bottom of a side wall, and is communicated witha sedimentation pool through a pipeline, and the pipeline is provided with a pneumatic pump; the bottom of the sedimentation pool is communicated with a plate-and-frame filter press through a pipeline, and a sludge pump is arranged on the pipeline; plural layers of mud baffles are arranged at the top of the sedimentation pool, and the lengths of the mud baffles are sequentially decreased from inside to outside; and the plate-and-frame filter press separates precipitates into a cold-rolled acid and mud cake, and the mud cake is recovered. According to the system, the observation opening is additionally formed to confirm the liquid outlet condition of the desilicication liquid storage tank; by additionally arranging the dirt discharge port and the pneumatic pump, the acid-containing mud slurry circularly flows between the sedimentation pool and the desilicication liquid storage tank; the lengths of the mud baffles in the sedimentation pool are improved, so that the sludge can be effectively prevented from entering the desilicication liquid storage tank; and the acid-containing mud slurry is digested and removed by utilizing an original acid regeneration technology.

Owner:SHANGHAI BAOSTEEL MAGNETICS

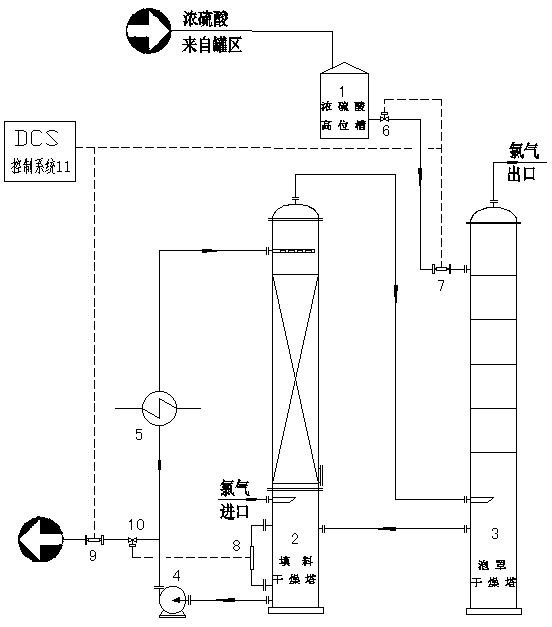

Online dilute sulfuric acid concentration control device in chlorine drying process based on DCS control system

PendingCN111240373AReduce consumptionReduce the frequency of manual samplingChlorine/hydrogen-chloride purificationGas treatmentControl systemProcess engineering

The invention relates to an online dilute sulfuric acid concentration control device in a chlorine drying process based on a DCS control system. The device comprises a concentrated sulfuric acid elevated tank, a packing drying tower, a bubble cap drying tower, a dilute sulfuric acid circulating pump and a dilute sulfuric acid cooler. An acid discharging control valve and an acid discharging flow meter are arranged on an acid discharging pipeline of the concentrated sulfuric acid elevated tank, the packing drying tower is provided with a liquid level sensor, and a sulfuric acid densimeter and an acid discharging adjusting valve are arranged on a dilute sulfuric acid discharging pipeline. The acid discharging adjusting valve is electrically connected with the liquid level sensor, the sulfuric acid densimeter is electrically connected with the overhead tank acid discharging control valve and the acid discharge flow meter, and the sulfuric acid densimeter, the acid discharging adjusting valve, the overhead tank acid discharging control valve, the acid discharging flow meter and the DCS form a control loop. On the basis of a DCS, a control loop is formed by the online density and the flow through a certain logic relationship, so that the consumption of concentrated sulfuric acid is reduced, the manual sampling frequency is reduced, the energy is saved, the consumption is reduced, and the safety and environmental protection risks are effectively reduced while fine control is realized.

Owner:TANGSHAN SANYOU CHLOR ALKALI

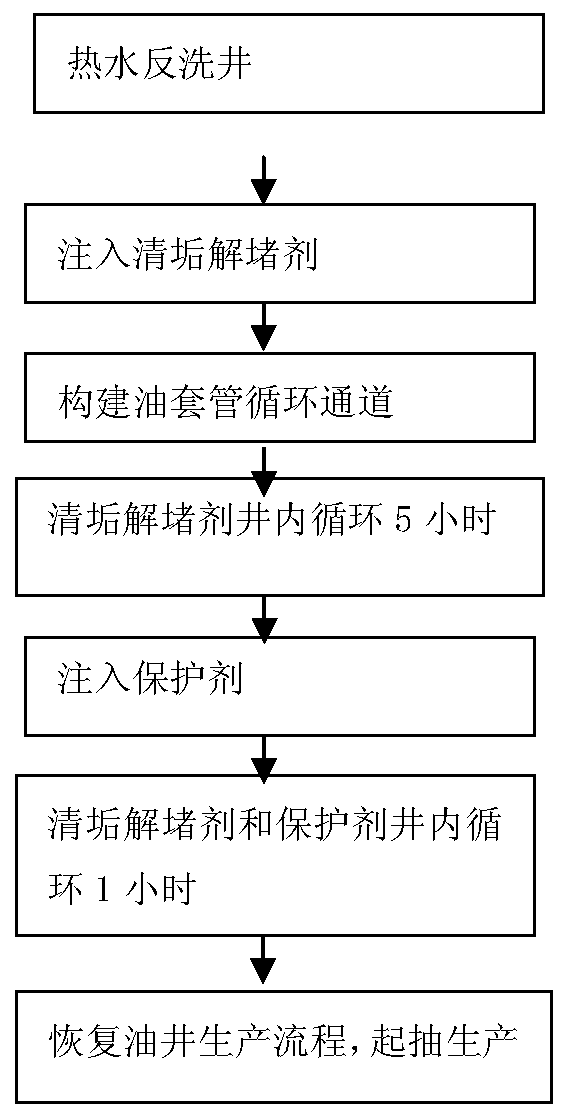

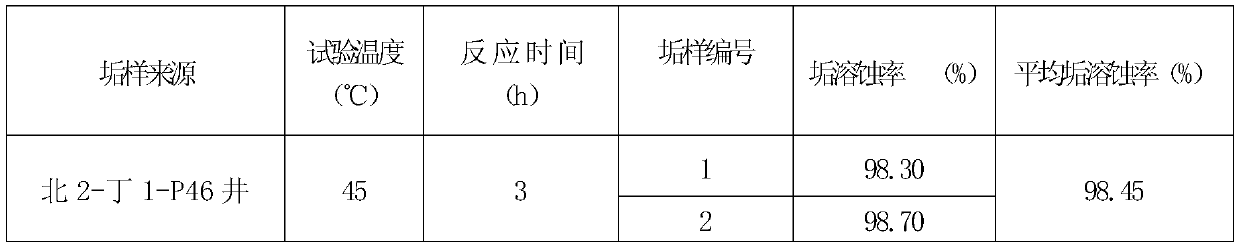

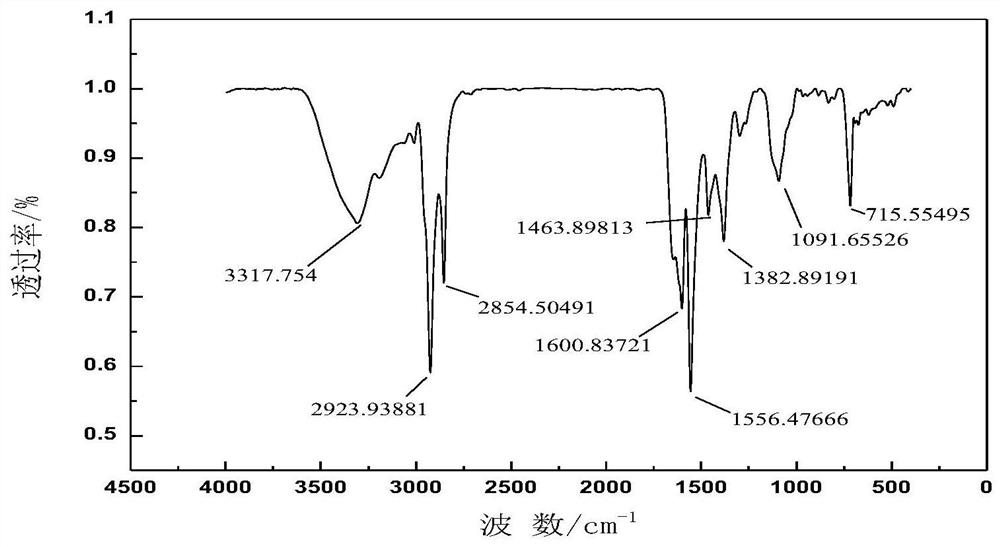

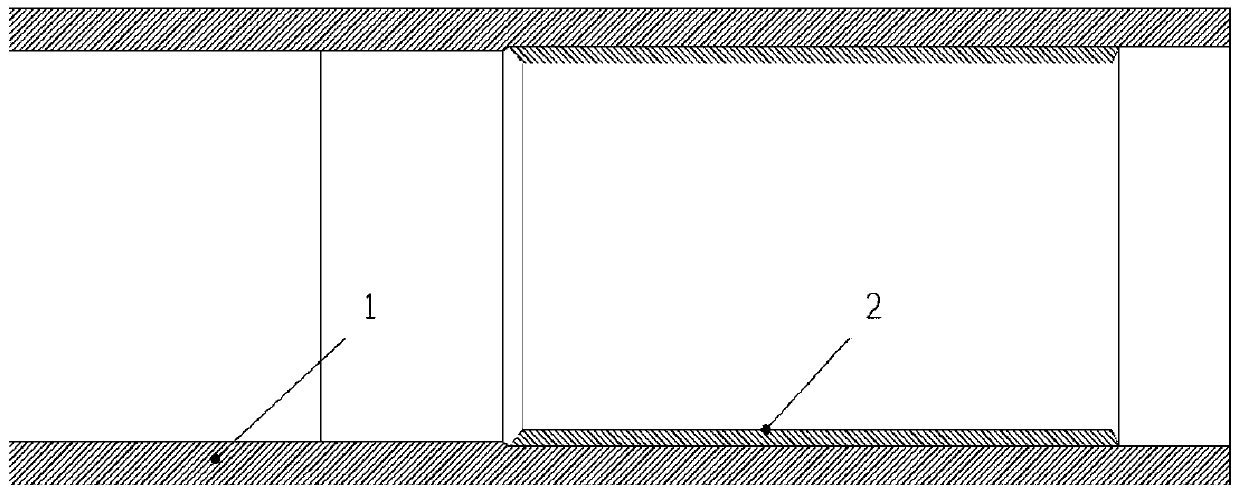

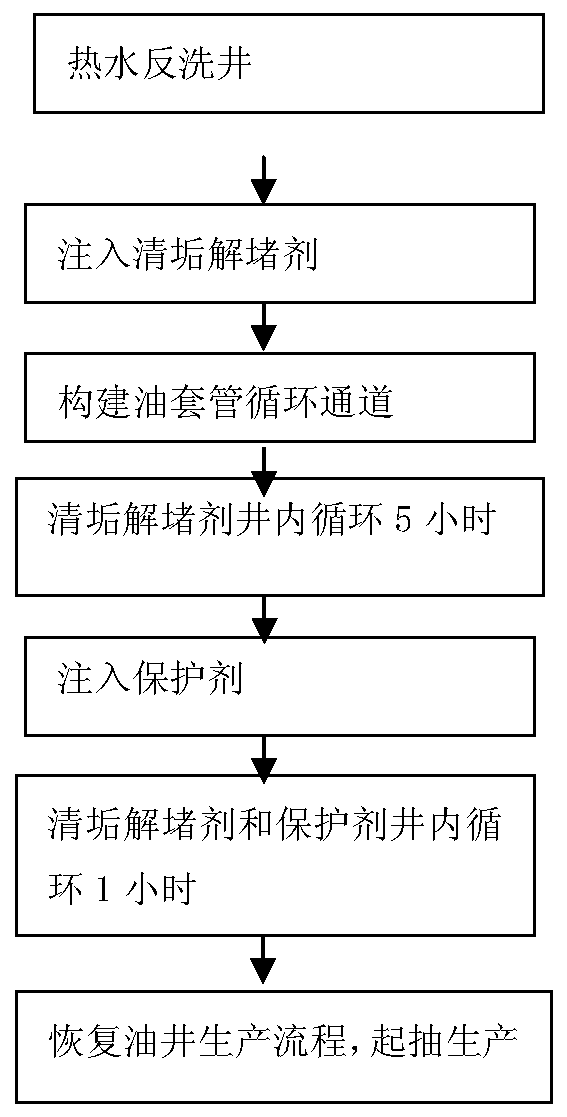

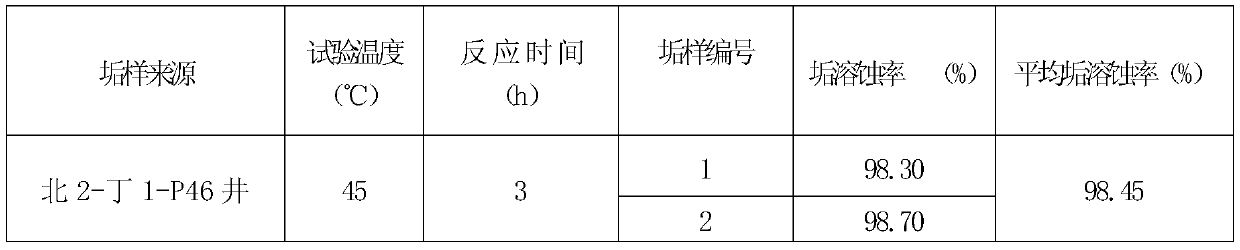

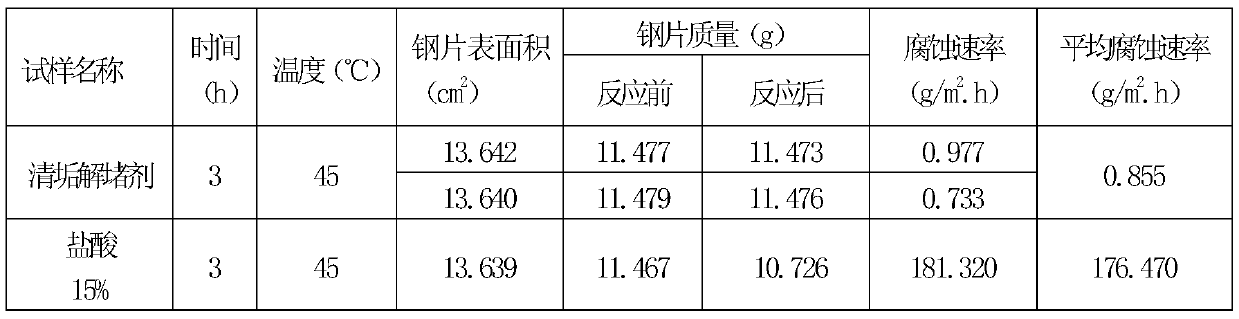

An integrated working fluid and process suitable for ASP flooding wells without external drainage, plugging and jamming

ActiveCN110439516BImprove runtime rateIncrease productionChemical industryCleaning apparatusAlkylphenolDioxyethylene Ether

The invention relates to non-discharge plug-removing stick-releasing integrated working fluid and process for a ternary compound combination flooding oil well. The problems that in an existing process, the utilization rate of medicaments is low, the overall cost is high, the construction time is long, and reaction residual liquid needs to be discharged are mainly solved. The non-discharge plug-removing stick-releasing integrated working fluid is characterized by being prepared from a scale clearing agent and a protective agent, and the scale clearing agent is prepared from the components in percentage by weight: 5%-7% of hydrochloric acid, 3%-5% of solid nitric acid, 0.3%-0.5% of alkylphenol ethoxylates, 1.0%-2.0% of triethanolamine, 0.5%-1.0% of imidazoline-ammonium-salt corrosion inhibitor and 90.2%-84.5% of water; the protective agent is prepared from the components in percentage by weight: 3.0%-5.0% of sodium hydroxide, 0.5%-1.0% of ethylenediaminetetraacetic acid disodium salt, 0.5%-1.0% of nonionic demulsifier SP169 and 96.0%-93.0% of water. The invention further provides a non-discharge plug-removing stick-releasing integrated process for the ternary compound combination flooding oil well. The non-discharge plug-removing stick-releasing integrated working fluid and process have the advantages of high efficiency of scale clearing and plug removing, low cost, safety and environmental protection.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

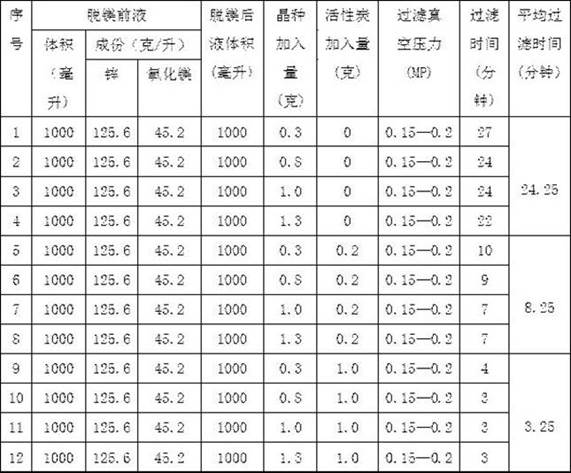

Method for harmlessly treating and recycling magnesium fluoride waste acid in zinc smelting process

ActiveCN113355517AReduce safety and environmental risksReduce manufacturing costProcess efficiency improvementActive agentLiquid copper

The invention relates to a method for harmlessly treating and recycling magnesium fluoride waste acid in a zinc smelting process. The method comprises the following steps of (1) harmlessly recycling the waste acid; (2) removing magnesium from a desorbed solution, adding a seed crystal, a modifier, a magnesium removal agent, lime and the like into the desorbed solution, heating, stirring and filtering to obtain a magnesium-removed solution and magnesium fluoride concentrate, adding tannic acid into the magnesium-removed solution to precipitate germanium, recovering germanium, filtering to obtain tannin germanium slag and a germanium-precipitated solution, firing the tannin germanium slag to obtain germanium concentrate, and feeding the germanium-precipitated solution to leached air for oxygen purification to remove iron and fluorine; (3) removing iron and fluorine from the germanium-deposited liquid through air oxidation; and (4) dechlorinating the liquid copper slag after iron and fluorine removal. According to the method, magnesium oxide is opened, harm of the magnesium oxide in a zinc hydrometallurgy solution system is reduced, and magnesium, fluorine and acid are recycled harmlessly; active agent is added, a problem of colloid formation in high zinc solution is solved, characteristics of the magnesium fluoride slag in the high zinc ion solution are changed, so that the magnesium fluoride slag formed a spongy structure and was easy to separate liquid from solid.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

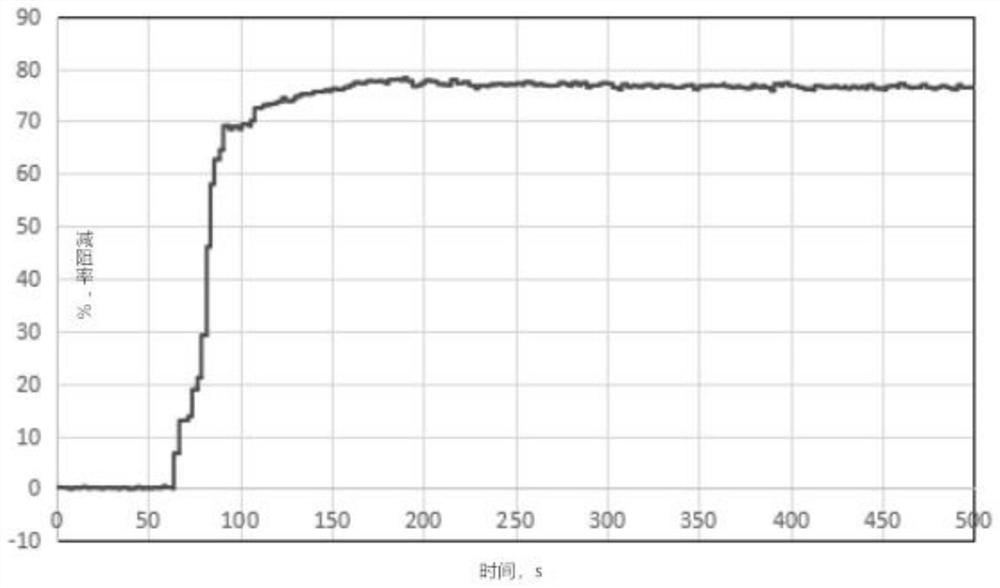

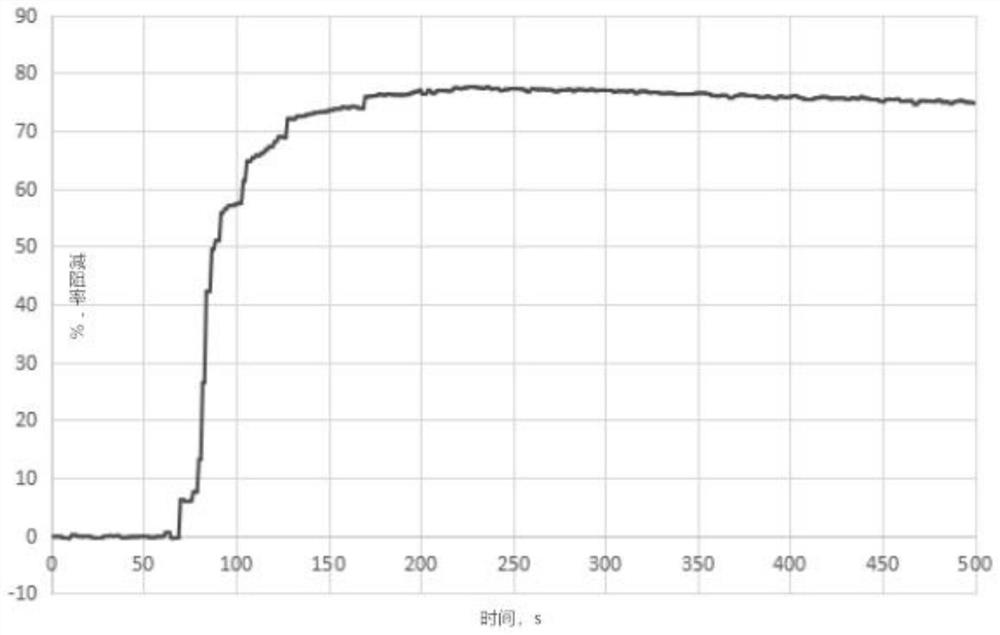

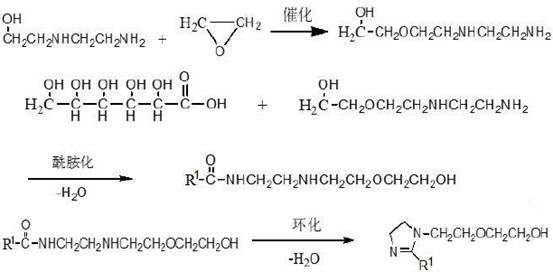

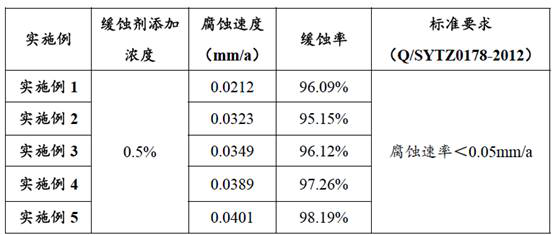

A kind of open high oxygen-containing circulating cooling water corrosion inhibitor and its preparation method and application

The invention provides an open high-oxygen circulating cooling water corrosion inhibitor and its preparation method and application. The corrosion inhibitor components include: 5-10% imidazoline monosaccharide acid solution, 1-3% zinc citrate, 5-8% sodium borate, 2-4% polyaspartic acid, 1-2% sodium tungstate, 4-7% sodium molybdate, 1-5% zinc acetate, 2-3% ethylenediamine tetramethylene base phosphoric acid, 1-2% pentasodium diethylenetriaminepentamethylene phosphonate and 2-4% hydroxyphosphonoacetic acid, and the balance is water; Ethylenediamine is used as a raw material, and hydroxyethylethylenediamine is first epoxidized, and then synthesized by acylation and cyclization. The corrosion inhibitor for open-type high-oxygen circulating cooling water has a good anti-corrosion effect on pipelines and equipment in high-oxygen open-type circulating cooling water systems. The addition amount is 0.5% and the temperature does not exceed 80°C. The corrosion inhibition efficiency is ≥ 95%, corrosion rate ≤ 0.05mm / a, physical properties meet the requirements of the standard Q / SYTZ0178-2012 "Technical Requirements and Test Methods for Sewage Corrosion Inhibitors".

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

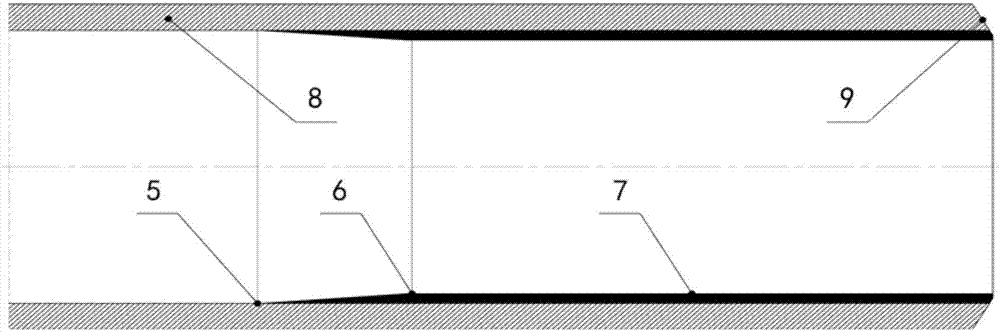

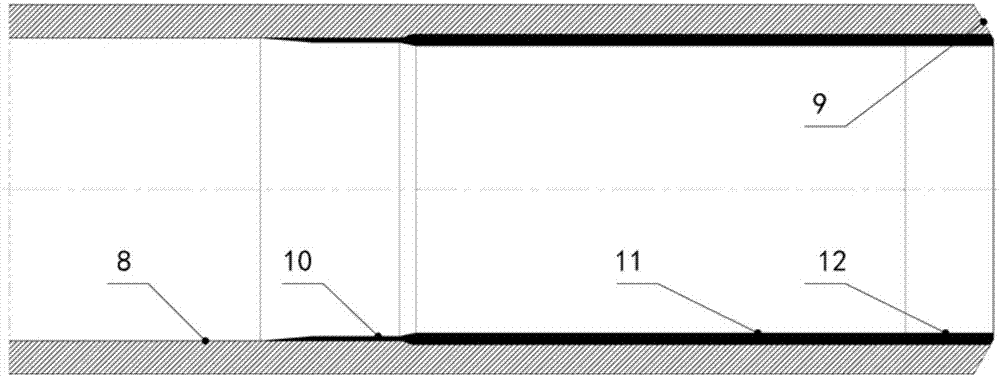

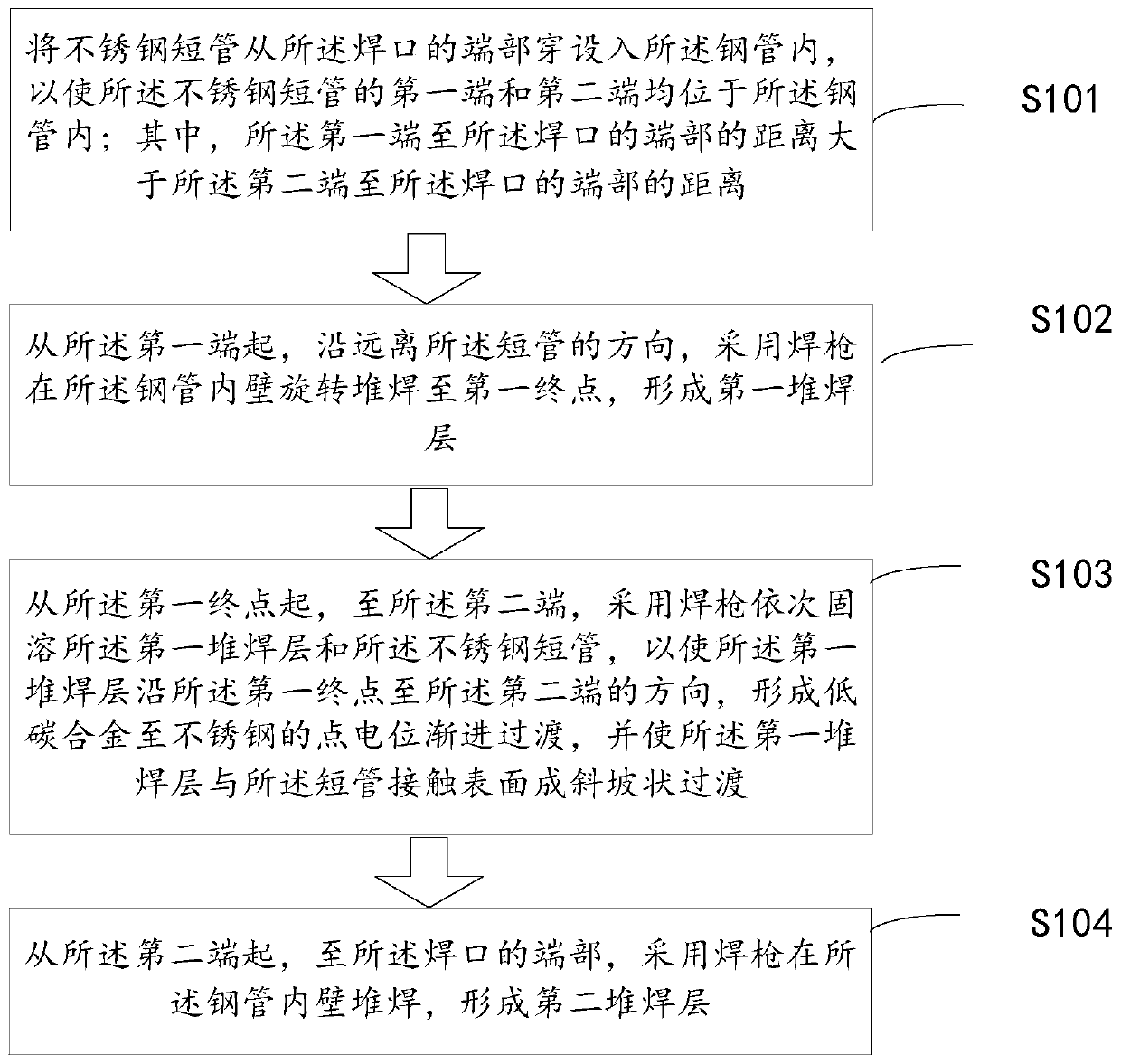

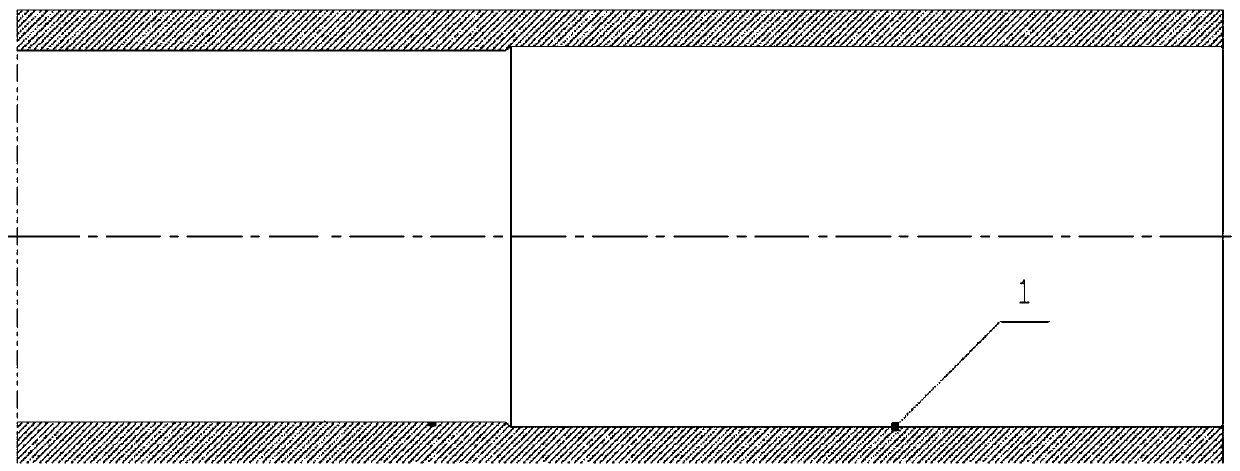

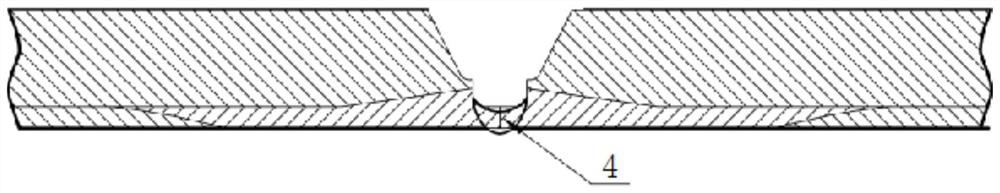

A method for pre-filling welded joints of steel pipes

InactiveCN107971606BGuaranteed anti-corrosion performancePoint potential dropArc welding apparatusMetal working apparatusSolution treatmentSS - Stainless steel

The invention discloses a pre-joint coating method for a welded junction of a steel pipe. The method comprises: penetrating a stainless steel short pipe into the steel pipe from an end part of the welded junction so as to enable both a first end and a second end of the stainless steel short pipe to be located in the steel pipe; adopting a welding gun to perform rotary build-up-welding on the inner wall of the steel pipe along the direction away from the short pipe from the first end so as to form a first build-up-welding layer; adopting the welding gun to sequentially perform solution treatment on the first build-up-welding layer and the stainless steel short pipe from a first end point to the second end so as to form point potential gradual transition from low-carbon alloy to stainless steel and to enable a contact surface of the first build-up-welding layer and the short pipe to be in slope-shaped transition; and adopting the welding gun to perform build-up-welding on the inner wall of the steel pipe from the second end to the end part of the welded junction to form a second build-up-welding layer. By means of the method, the technical problem existing the prior art that the difficulty of the anti-corrosion repairing operation in the steel pipe is high is solved, and the technical effect of reducing safety and environmental protection risks caused by corrosion and leakage of pipelines is realized.

Owner:CNPC RES INST OF ENG TECH +1

Non-discharge plug-removing stick-releasing integrated working fluid and process for ternary compound combination flooding oil well

ActiveCN110439516AImprove runtime rateIncrease productionChemical industryCleaning apparatusWorking fluidAlkylphenol

The invention relates to non-discharge plug-removing stick-releasing integrated working fluid and process for a ternary compound combination flooding oil well. The problems that in an existing process, the utilization rate of medicaments is low, the overall cost is high, the construction time is long, and reaction residual liquid needs to be discharged are mainly solved. The non-discharge plug-removing stick-releasing integrated working fluid is characterized by being prepared from a scale clearing agent and a protective agent, and the scale clearing agent is prepared from the components in percentage by weight: 5%-7% of hydrochloric acid, 3%-5% of solid nitric acid, 0.3%-0.5% of alkylphenol ethoxylates, 1.0%-2.0% of triethanolamine, 0.5%-1.0% of imidazoline-ammonium-salt corrosion inhibitor and 90.2%-84.5% of water; the protective agent is prepared from the components in percentage by weight: 3.0%-5.0% of sodium hydroxide, 0.5%-1.0% of ethylenediaminetetraacetic acid disodium salt, 0.5%-1.0% of nonionic demulsifier SP169 and 96.0%-93.0% of water. The invention further provides a non-discharge plug-removing stick-releasing integrated process for the ternary compound combination flooding oil well. The non-discharge plug-removing stick-releasing integrated working fluid and process have the advantages of high efficiency of scale clearing and plug removing, low cost, safety and environmental protection.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

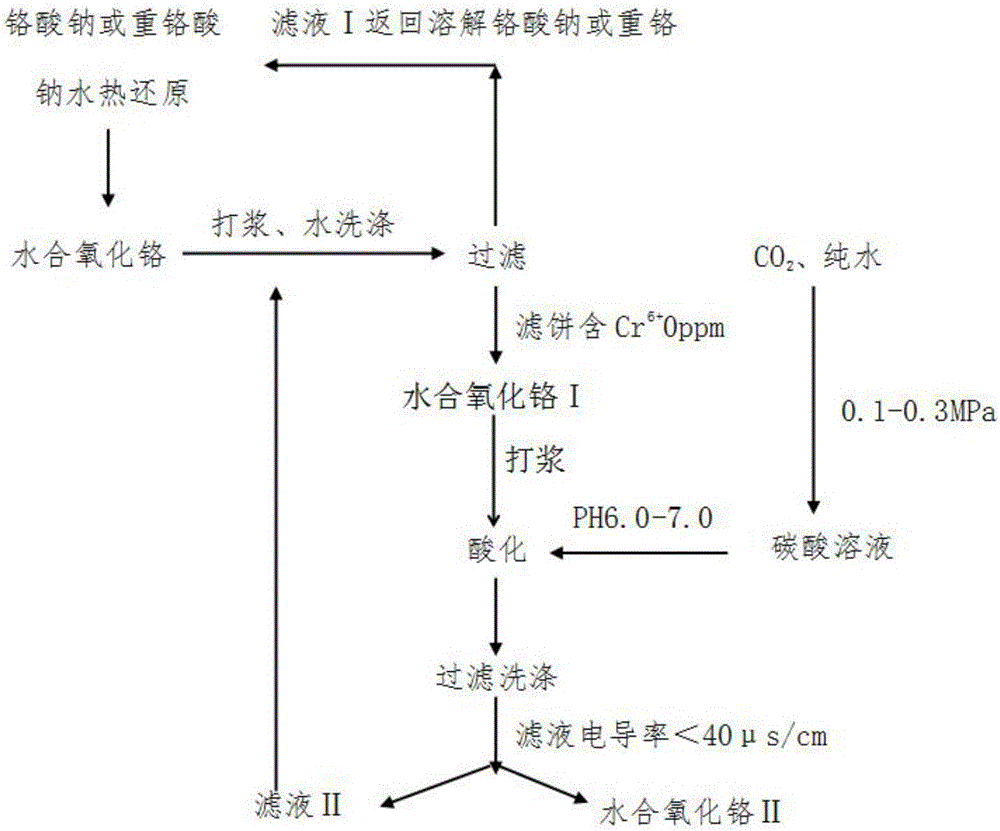

Washing method for obtaining low-sulfur hydrated chromic oxide

ActiveCN106365202AImprove product qualityWill not affect product qualityChromium trioxideOrganic acidSulfur

The invention discloses a washing method for obtaining low-sulfur hydrated chromic oxide. The washing method includes the steps that (1) hydrated chromic oxide prepared from sodium chromate or sodium dichromate in a hydrothermal-reduction mode is pulped and then separated through a filtering machine, countercurrent washing is carried out, and first filtered liquid and first hydrated chromic oxide are obtained; (2) the first hydrated chromic oxide is pulped, a carbonic acid solution is added at the room temperature, the mixture is stirred, the pulped liquid is acidized, the temperature is increased and then kept, and hydrated-chromic-oxide neutralized slurry liquid is obtained; (3) the hydrated-chromic-oxide neutralized slurry liquid is separated through a filtering machine, countercurrent washing is carried out, and second filtered liquid and second hydrated chromic oxide are obtained. According to the washing method, the series of problems that when the hydrated chromic oxide is washed, inorganic acid or organic acid serves as an acidifying agent, low-sulfur hydrated chromic oxide cannot be obtained, the production cost is high, and safety and environmental protection risks exist are solved; by means of the washing method for obtaining the low-sulfur hydrated chromic oxide, the low-sulfur hydrated chromic oxide can be obtained, the using amount of washing water is effectively saved, the washing efficiency of the hydrated chromic oxide is improved, and the production cost is reduced.

Owner:SICHUAN YINHE CHEM +1

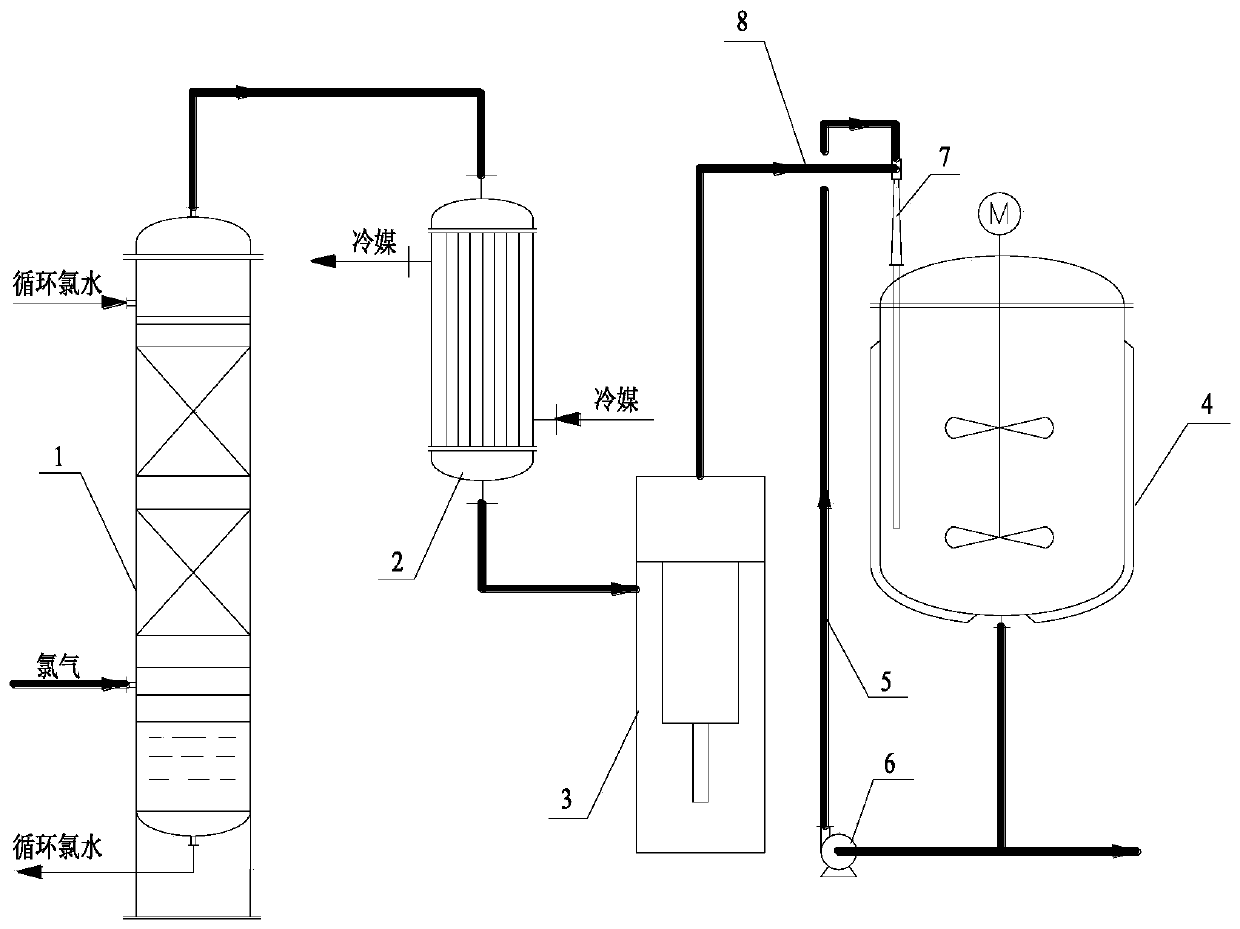

Device and method for producing adc by chlorine oxidation

ActiveCN107382791BAvoid risk of leakageLow investment costOrganic chemistryProcess engineeringEnvironmental engineering

The invention discloses a device and a method for producing ADC by a chorine oxidation method. The device comprises a water-washing tower, a cooler, a water mist separator and a chlorine inlet reactor which are connected with one another sequentially; the chlorine inlet reactor comprises a reaction kettle, a circulating pipeline, a circulating pump and an ejector or a Venturi tube; a liquid inlet of the ejector or the Venturi tube is connected with one end of the circulating pipeline; the other end of the circulating pipeline is connected with a discharging opening of the reaction kettle; a liquid outlet of the ejector or the Venturi tube is connected with a feeding opening of the reaction kettle; a suction opening of the ejector or the Venturi tube is communicated with a chloride discharge pipe of the water mist separator; and the circulating pump is arranged on the circulating pipeline. The device and the method for producing the ADC by the chorine oxidation method has the following advantages: a sulfuric acid drying tower is not used and a large amount of waste sulfuric acid is not generated; a chlorine compressor is not used, so the investment cost is reduced and the risk of high-pressure chlorine leakage is avoided; a high-pressure chlorine pipeline is not needed, so a large amount of leakage accidents are reduced; and the economic benefit is high, and safety and environmental friendliness are achieved.

Owner:内蒙古锦洋化学工业有限公司 +1

Pre-joint-coating method for welded junction of steel pipe

InactiveCN107971606AGuaranteed anti-corrosion performancePoint potential dropArc welding apparatusMetal working apparatusGradual transitionSteel tube

The invention discloses a pre-joint-coating method for a welded junction of a steel pipe. The pre-joint-coating method comprises the steps that a stainless steel short pipe is inserted into the steelpipe from the end of the welded junction, so that a first end and a second end of the stainless steel short pipe are located in the steel pipe; from the first end, in the direction away from the shortpipe, a welding gun rotates and performs bead weld to the inner wall of the steel pipe to a first end point to form a first welding layer; from the first end point to the second end, the first welding layer and the stainless steel short pipe are solidly dissolved by the welding gun in order to form a point potential gradual transition from low carbon alloy to stainless steel, and the contact surface of the first welding layer and the short pipe is formed into a slope-like transition; and from the second end to the end of the welded junction, the bead weld of the inner wall of the steel pipe is performed by the welding gun to form a second welding layer. The pre-joint-coating method for the welded junction of the steel pipe solves the technical problem in the prior art that the anticorrosion joint coating for the interior of the steel pipe is difficult, and achieves the technical effect of reducing the risk of safety and environmental protection caused by corrosion leakage of the pipeline.

Owner:CNPC RES INST OF ENG TECH +1

Oil sludge recycling system and method

InactiveCN111635096ARealize timely recyclingReduce labor intensitySludge treatment by de-watering/drying/thickeningInsulationProcess engineeringOil sludge

The invention provides an oil sludge recycling system and method. The oil sludge recycling system comprises a treatment tank, the treatment tank is respectively communicated with a mixing pipeline anda thermal washing pipeline respectively through an oil discharge pipeline, the treatment tank is connected to a heating mechanism, and the mixing pipeline is communicated with a crude oil metering transfer station; the thermal washing pipeline is communicated with a casing pipe well washing pipeline and an oil extraction pipe arranged at a wellhead in parallel through pipelines; wherein the casing pipe well washing pipeline is led into a casing pipe, an outlet of the oil extraction pipe is communicated with an oil outlet pipe and a single-quantity pipeline in parallel, the oil outlet pipe ofeach oil well is communicated with the mixing pipeline, and valves are arranged on the thermal washing pipeline, the casing pipe well washing pipeline, the single-quantity pipeline, the mixing pipeline and the oil outlet pipe. Timely recovery treatment of landing crude oil is achieved, the recovery rate reaches 99%, oil sludge does not need to be transferred to an oil sludge treatment plant for unified treatment, the labor intensity of the staff is relieved, the treatment time and cost are saved, and safety and environmental protection risks are reduced. The system provided by the invention not only can recover oil, but also has multiple functions of thermal washing, paraffin removal, dosing and single-quantity operation, and is economical, environment-friendly and practical.

Owner:PETROCHINA CO LTD

Method for negative-pressure unloading of sulfuric acid tank cars of train

InactiveCN101648693AReduce safety and environmental risksImprove efficiencySpecial dispensing meansMechanical engineeringSulfuric acid

The invention discloses a method for the negative-pressure unloading of the sulfuric acid tank cars of a train. The method comprises the following unloading technological steps: (1) dragging one to aplurality of sections of sulfuric acid train tank cars on a negative-pressure acid unloading station, putting at a position corresponding to an unloading crane, fixing, then opening a manhole of eachtank car, inserting the unloading crane and fixing; (2) closing an outlet valve of a vacuum tank, starting a pump, opening an acid filling valve of the crane, filling acid into the acid unloading crane for exhausting; (3) after completing exhaustion, stopping filling the acid, opening an outlet of the vacuum tank to a pump tank acid valve and then beginning to unload the acid; and (4) after completing unloading, pulling out the unloading crane, recovering the manholes and handing up the empty cars. The invention has the effects or advantages of no requirement on assembling connection tubes andno consideration on the airtightness of the connection tubes. Because of negative-pressure unloading, the invention has very small risk on safety and environmental protection, high efficiency and easy operation, the unloading number of each batch can reach 15 cars and unloading positions can be properly increased according to requirements.

Owner:WENGFU (GRP) CO LTD

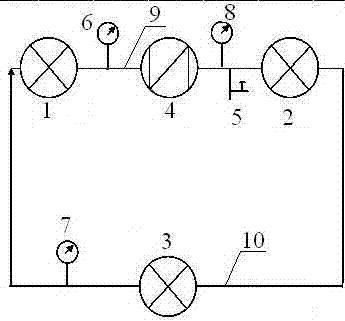

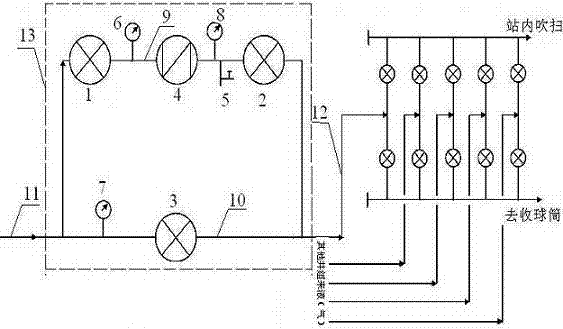

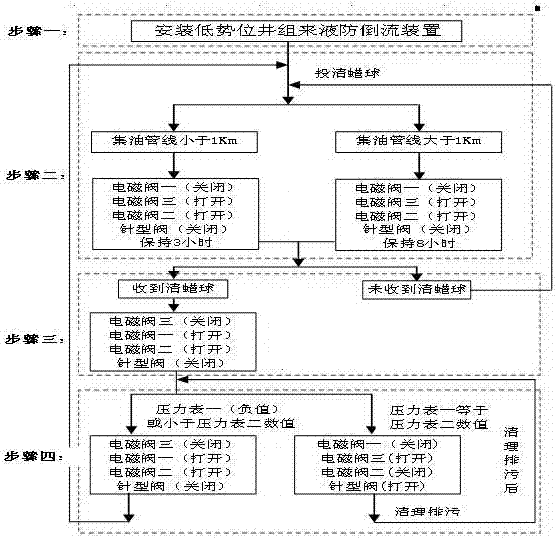

Anti-backflow device and technology for low-potential well group incoming fluid

ActiveCN105156058BPrevent effusion from freezingReduce production management difficultiesSealing/packingBit lineLine tubing

The invention provides an anti-backflow device for incoming liquid in a low-potential well group, which includes an anti-backflow pipeline and a straight-through pipeline. The anti-backflow pipeline and the straight-through pipeline are connected in parallel, and one end of the parallel connection communicates with the incoming liquid pipeline of the low-potential well group. One end is connected with the liquid inlet pipeline of the main shut-in well group; the anti-backflow pipeline is provided with solenoid valve 1, pressure gauge 1, check valve, pressure gauge 3, needle valve, solenoid valve 2 in sequence according to the direction of entering the station. The pipeline is provided with pressure gauge 2 and solenoid valve 3 in sequence according to the direction of entering the station. The invention can prevent a single well from backflowing to the wellhead of a single well due to pressure relief from other well groups in the station, reduce safety and environmental protection risks, prevent oil and gas well gathering and transportation pipelines from accumulating and freezing, and reduce difficulties in production and management of oil and gas wells.

Owner:PETROCHINA CO LTD

A kind of method for recovering magnesium fluoride polluted acid by harmless treatment in zinc smelting process

ActiveCN113355517BChange propertiesTroubleshooting Separation DifficultiesProcess efficiency improvementLiquid copperActive agent

The invention relates to a method for harmless treatment and recovery of magnesium fluoride polluted acid in a zinc smelting process, comprising: 1) harmless reuse of polluted acid; Seeds, modifiers, demagnesiasing agents, lime, etc., heat up and stir, filter to obtain demagnesium solution and magnesium fluoride concentrate, add tannic acid to the demagnesium solution to precipitate germanium, recover germanium, and filter to obtain germanium tannin Slag and germanium precipitation liquid, tannin and germanium slag are burned to obtain germanium concentrate, and the post germanium precipitation liquid is sent to leaching air for oxygen purification to remove iron and fluorine; 3) air oxidation to remove iron and fluorine after germanium precipitation; 4) iron removal After fluorine, the liquid copper slag is dechlorinated. The invention achieves the open circuit of magnesium oxide, reduces the harm of magnesium oxide in the hydrometallurgical zinc solution system, and recovers magnesium, fluorine and acid harmlessly; by adding active agent, the problem of easy formation of colloid in high zinc-containing solution is solved, and fluorine is changed. The characteristics of magnesium fluoride slag in high zinc ion solution make magnesium fluoride slag form a spongy structure, which is easy for liquid-solid separation.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

Method for preparing anhydrous sodium chromate

ActiveCN106629849BImprove qualityImprove resource utilizationChromates/bichromatesBulk chemical productionProduction lineLiquid ratio

The present invention discloses a method for preparing anhydrous sodium chromate. The method comprises the steps of mixing a sodium chromate alkali solution with a carbonating solution in proportion of (1:1) to (8:1), and then, adjusting the pH to 6.5-8.5 to obtain a pretreatment solution of sodium chromate; placing the pretreatment solution of sodium chromate in an evaporation crystallizer for vacuum evaporation at the temperature of 80 DEG C to 120 DEG C under the pressure of 0.01 MPa to 0.09 MPa; and when the solid-to-liquid ratio reaches 10%-50% through vacuum evaporation, performing solid-liquid separation at the temperature of 70 DEG C or above to obtain anhydrous sodium chromate and a filtrate. Based on the technology characteristics of sodium dichromate preparation by a carbonation method, high-quality anhydrous sodium chromate is successfully prepared by the method disclosed by the invention, with the main content being equal to or greater than 99.5% and the content of all impurities such as sulfate being less than 0.001%; moreover, the product does not absorb moisture or cake even if stored for a long term, and has good fluidity. The problems of sodium chromate tetrahydrate on easy moisture absorption, caking and poor fluidity are successfully solved. The method also brings into play the superiority of a production process of preparing sodium dichromate from a chromium salt by the carbonation method, so that two high-quality chemical products can be produced on one production line.

Owner:SICHUAN YINHE CHEM

A submersible direct drive screw pump huff and puff oil recovery device

ActiveCN105422053BOptimize work processImprove construction efficiencyFluid removalWell/borehole valve arrangementsElectricityEconomic benefits

The invention provides a huff-and-puff oil production device with a submersible directly-driven screw pump. The huff-and-puff oil production device comprises an underground automatic water injection switch for realizing water injection and oil production channel switching and a submersible directly-driven screw pump, wherein a liquid outlet in the upper end of the underground automatic water injection switch is connected with an oil pipe, and a liquid inlet in the lower end of the underground automatic water injection switch is connected with an oil outlet in the upper end of the submersible directly-driven screw pump through the oil pipe; the submersible directly-driven screw pump comprises a screw pump, a flexible shaft, an upper protect tor, a lower protector, a submersible motor and a centralizer which are non-coaxially connected from top to bottom; the upper end of the screw pump is connected with the lower end of the underground automatic water injection switch; and the screw pump and the submersible motor are respectively electrically connected to a submersible cable outside a wellhead. The huff-and-puff oil production device is free of repeatedly tripping and has the characteristics of simple and convenient operation flow, high construction efficiency, safety, environment friendliness, low risk and the like; and due to the adoption of the lifting way, the huff-and-puff oil production device has the characteristics of low rotating speed and large torque and is suitable for a well with low liquid quantity, the eccentric wear of pipe poles is eliminated, the maintenance-free period of an oil well is prolonged, and the economic benefit can be effectively increased.

Owner:PETROCHINA CO LTD

A bimetal welding construction process method for surfacing prefabricated inner patch bimetal pipes

ActiveCN112548276BReliable bimetallic weldsSolving the challenge of reliable fusionArc welding apparatusAlloyWeld seam

Owner:CHINA PETROLEUM & CHEM CORP +2

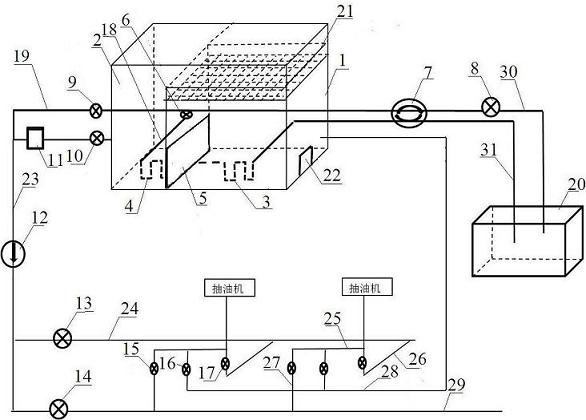

A submersible electric reciprocating pump huff and puff oil production device

ActiveCN105422065BOptimize work processImprove construction efficiencyFlexible member pumpsFluid removalEconomic benefitsLinear motor

The invention belongs to the technical field of mechanical oil production and particularly provides a huff-and-puff oil production device with an electric submersible reciprocating pump. The huff-and-puff oil production device comprises an underground automatic water injection switch (6) for realizing water injection and oil production channel switching and an electric submersible reciprocating pump, wherein a liquid outlet (9) in the upper end of the underground automatic water injection switch (6) is connected with an oil pipe (4), and a liquid inlet (10) in the lower end of the underground automatic water injection switch (6) is connected with an oil outlet in the upper end of an electric submersible reciprocating pump through the oil pipe (4). The huff-and-puff oil production device is free of repeatedly tripping and has the characteristics of simple and convenient operation flow, high construction efficiency, safety, environment friendliness, low risk and the like as comparison with the traditional huff-and-puff oil production process. In addition, due to the adoption of an electric submersible reciprocating pump (a linear motor) device adopted in a lifting way, underground driving link is omitted, the eccentric wear of pipe poles is eliminated, the maintenance-free period of an oil well is prolonged, the huff-and-puff oil production device is suitable for a well with low liquid quantity, and the economic benefit can be effectively increased.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com