Anti-backflow device and technology for low-potential well group incoming fluid

A low-potential, anti-backflow technology, which is applied in wellbore/well components, earthwork drilling, sealing/package, etc., can solve problems such as the inability to effectively control the backflow of incoming fluid in the well group, and reduce production management difficulties and reduce Safety and environmental protection risks, the effect of preventing fluid accumulation and freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

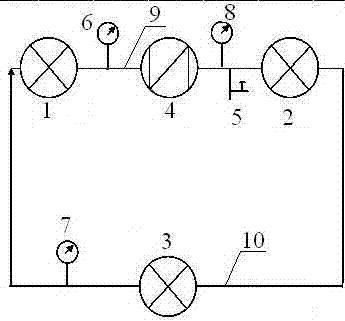

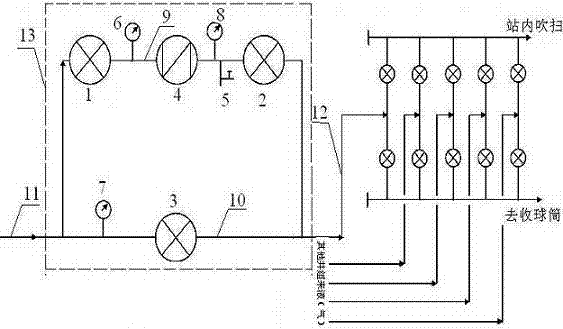

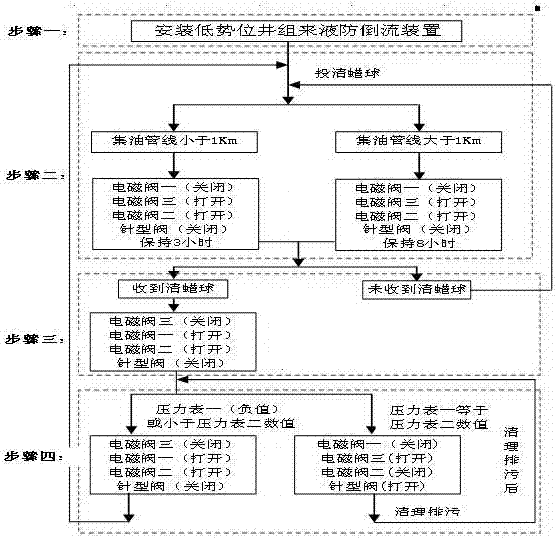

[0025] This embodiment provides a figure 1 , 2 The low-potential well group incoming liquid anti-backflow device 13 shown includes an anti-backflow pipeline 9 and a straight-through pipeline 10, the anti-backflow pipeline 9 and the straight-through pipeline 10 are connected in parallel, and one end of the parallel connection is connected to the low-potential well group incoming liquid pipeline 11 connected, and the other end is connected with the liquid inlet pipeline 12 of the main shut-in group;

[0026] The anti-backflow pipeline 9 is sequentially provided with a solenoid valve 1, a pressure gauge 6, a check valve 4, a pressure gauge 3 8, a needle valve 5, and a solenoid valve 2 according to the direction of entering the station. Station direction is provided with pressure gauge two 7, solenoid valve three 3 in turn.

[0027] In this embodiment, the electromagnetic valve 1 mainly controls the two-way incoming liquid of the anti-backflow pipeline 9, switches the incoming l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com