Solid solution transition close potential stainless steel bead welding method for pre-repairing of steel pipeline welded junction

A stainless steel and pipeline technology, applied in welding equipment, tubular objects, arc welding equipment, etc., can solve the problems of not involving stainless steel filled short pipes, potential difference, bimetallic interface galvanic corrosion, etc., to extend the online service period, reduce Waste of resources, to achieve the effect of factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

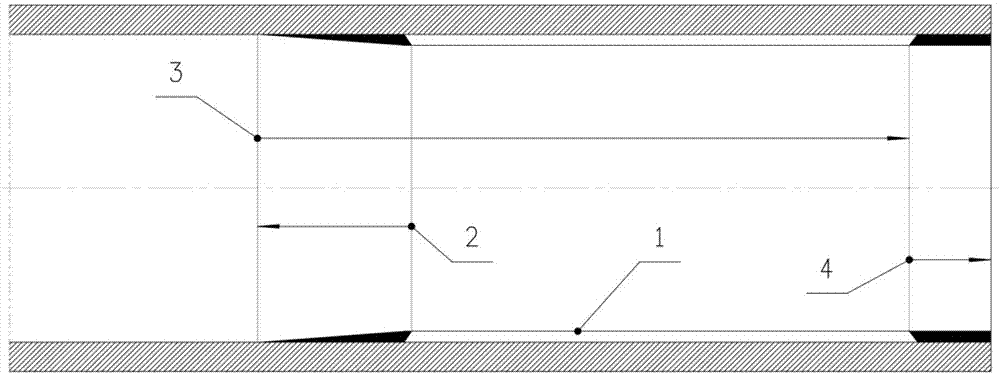

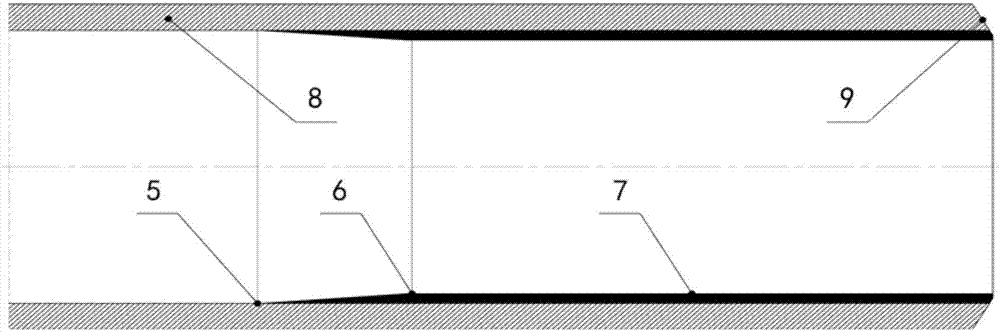

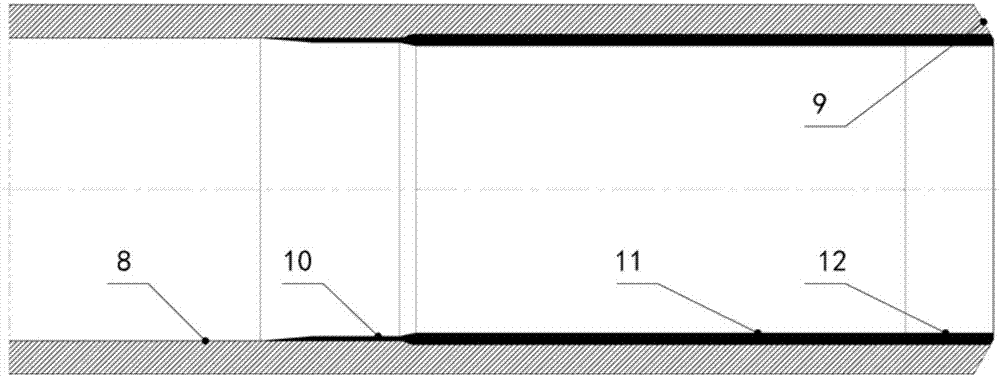

[0028] The invention pre-fills short stainless steel tubes on the inner wall of the steel pipe end, starts from the inner end surface of the short tube, and adopts a TIG numerical control surfacing welding machine from the outside to the inside when the steel pipe is rotated. , stop wire feeding when the surfacing reaches a certain width ( Figure 4 ); the TIG welding torch is axially moved from the inside to the outside, and the surfacing layer is re-melted by the argon arc and the stainless steel filling short tube is heated and melted. The outermost end of the tube ( Figure 5 ), and then use the MIG method to surfacing again to the end of the steel pipe by swinging and moving the distance wire feeding ( Image 6 ); After the solid solution surfacing is completed, the groove and the inner wall of the pipe end are mechanically processed, and the steel pipe pre-filling joint is gradually transitioned to the near-potential solid solution surfacing process. The final product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com