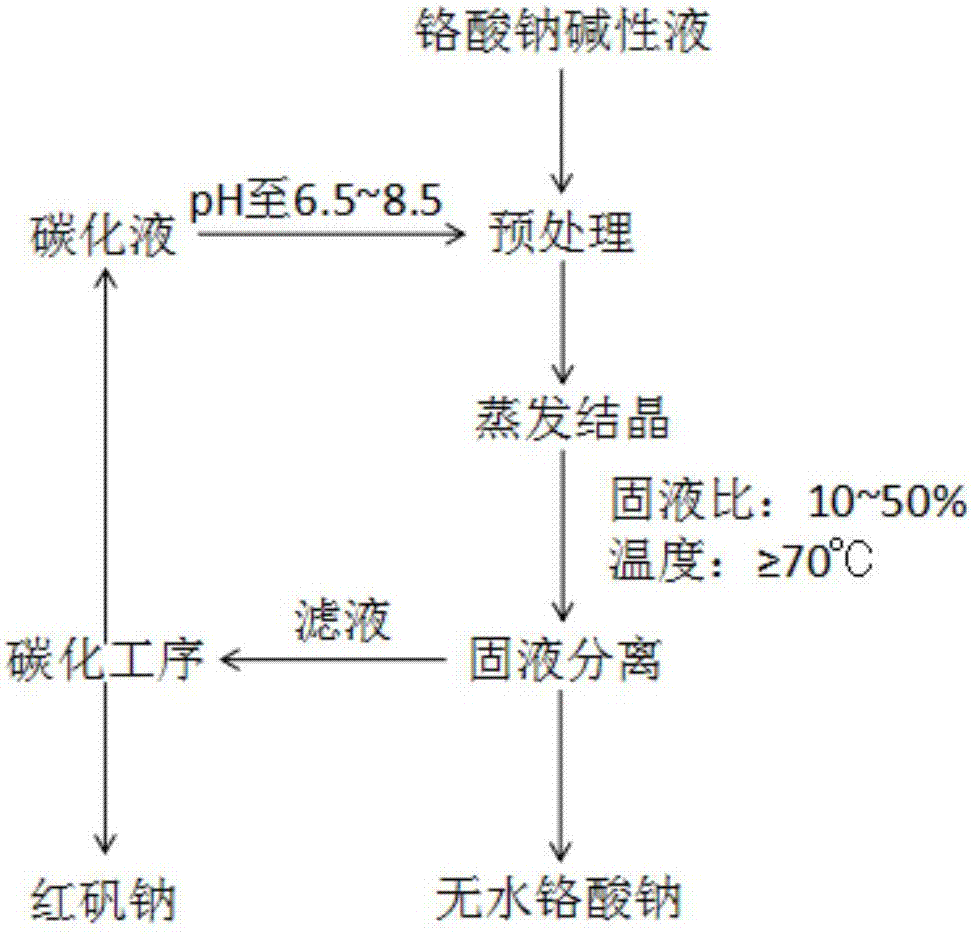

Method for preparing anhydrous sodium chromate

An anhydrous sodium chromate and sodium chromate technology, which is applied in the production of chromate/dichromate and bulk chemicals, can solve the problems of waste of resources and high production costs, improve manpower and solve the problem of easy moisture absorption , the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing anhydrous sodium chromate, comprising the following steps:

[0027] Step 1, the sodium chromate alkaline solution 8m 3 Carbonation solution 1m prepared by carbonization method 3 Add it into the pretreatment storage tank, take a sample and analyze the pH to be 8.2, and retest the pH to be 8.3 after stirring at room temperature for 15 minutes to obtain the sodium chromate pretreatment solution; the concentration of the carbonized solution is 925g L -1 (in Na 2 Cr 2 o 7 2H 2 O meter), pH is 5.8;

[0028]Step 2. Pump the sodium chromate pretreatment solution to the continuous evaporation crystallizer, use steam as the heat source, raise the temperature to 81°C, start the vacuum pump, and control the internal pressure of the evaporator at -0.09MPa; Feed rate of sodium chromate pretreatment liquid, observe the precipitation of sodium chromate crystals, when the solid-liquid ratio is 50%, discharge to the concentrated liquid storage tank;

[0029]...

Embodiment 2

[0031] A method for preparing anhydrous sodium chromate, comprising the following steps:

[0032] Step 1, the sodium chromate alkaline solution 7m 3 Carbonation solution 2m prepared by carbonization method 3 Add it into the pretreatment storage tank, sample and analyze the pH to be 7.6, retest the pH to be 7.6 after stirring at room temperature for 15 minutes, and obtain the sodium chromate pretreatment solution; the concentration of the carbonized solution is 925g L -1 (in Na 2 Cr 2 o 7 2H 2 O meter), pH is 5.8;

[0033] Step 2: Pump the sodium chromate pretreatment solution to the evaporation crystallizer, use steam as the heat source, raise the temperature to 90°C, start the vacuum pump, and control the internal pressure of the evaporator at -0.07MPa. During the evaporation process, the feeding rate of the sodium chromate pretreatment liquid is well controlled, and the precipitation of sodium chromate crystals is observed. When the solid-liquid ratio is 42%, the mater...

Embodiment 3

[0036] A method for preparing anhydrous sodium chromate, comprising the following steps:

[0037] Step 1, the sodium chromate alkaline solution 6m 3 Carbonation solution 3m prepared by carbonization method 3 Add in the pretreatment storage tank, take a sample and analyze the pH7.1, retest the pH7.15 after stirring at room temperature for 15 minutes, and obtain the sodium chromate pretreatment solution; the concentration of the carbonized solution is 925g L -1 (in Na 2 Cr 2 o 7 2H 2 O meter), pH is 5.8;

[0038] Step 2: Pump the sodium chromate pretreatment solution to the evaporation crystallizer, use steam as the heat source, raise the temperature to 102°C, start the vacuum pump, and control the pressure inside the evaporator at -0.04MPa. During the evaporation process, the feeding rate of the sodium chromate pretreatment liquid is well controlled, and the precipitation of sodium chromate crystals is observed. When the solid-liquid ratio is 36%, the material is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com