A kind of open high oxygen-containing circulating cooling water corrosion inhibitor and its preparation method and application

A technology of circulating cooling water and high oxygen content, which is applied in the field of metal anti-corrosion materials, can solve the problems of limited corrosion inhibition effect, and achieve the effect of simple preparation method, simple production process and excellent corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

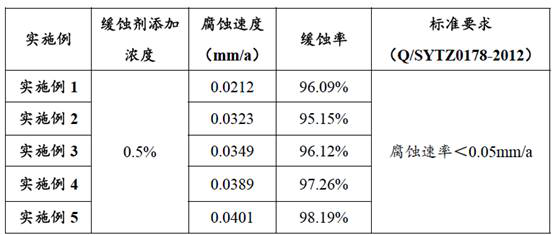

Embodiment 1

[0040] 1. Preparation of open-type high-oxygen circulating cooling water corrosion inhibitor and detection of corrosion inhibition effect:

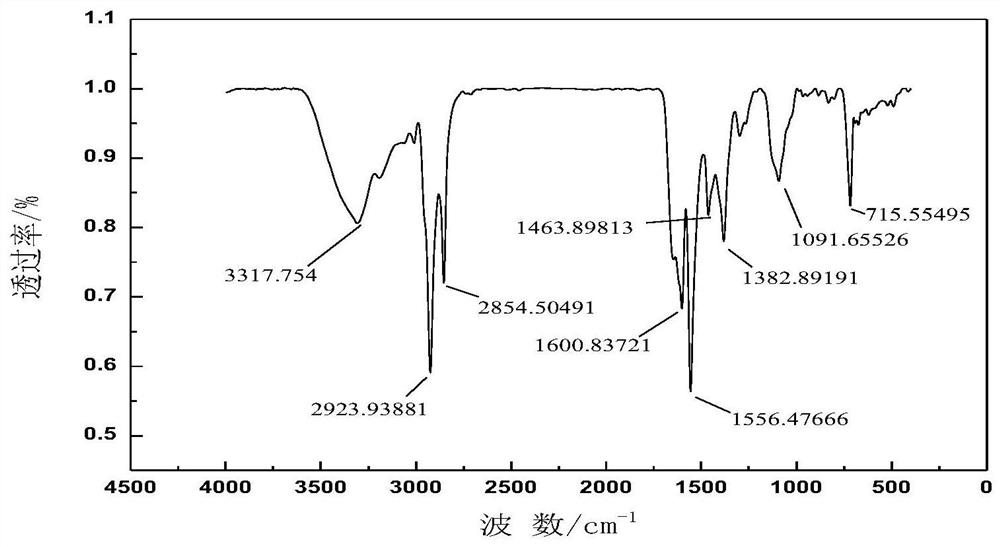

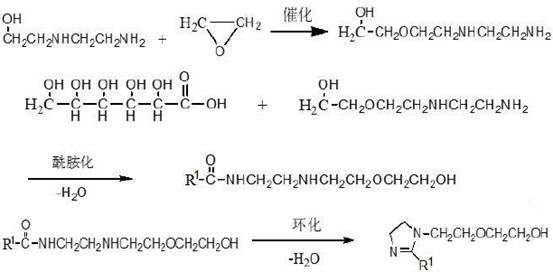

[0041]1) Catalyze reaction of hydroxyethylethylenediamine and ethylene oxide at a molar ratio of 1:1 under alkaline conditions at 50°C for 2 hours. After the reaction is completed, add 1 molar ratio of gluconic acid and react at a temperature of 120°C 4h, and then the temperature was raised to 190°C, and reacted for 8 hours to obtain a water-soluble imidazoline gluconate mixture. The infrared spectrogram of gained imidazoline gluconate is as attached figure 1 shown at 1600cm -1 、1556cm -1 There is a strong absorption peak at 1600cm -1 Nearby is the characteristic absorption peak of imidazoline C=N double bond absorption peak, 1556cm -1 where is the C-N single-bond stretching vibration. And at 1610cm -1 There is an absorption band nearby, indicating that the reaction product is an imidazoline product.

[0042] 2) Mix 10 parts by wei...

Embodiment 2

[0047] 1. Preparation of open-type high-oxygen circulating cooling water corrosion inhibitor and detection of corrosion inhibition effect:

[0048] 1) Catalyze reaction of hydroxyethylethylenediamine and ethylene oxide at a molar ratio of 1:1 under alkaline conditions at 60°C for 2 hours. After the reaction is completed, add 1 molar ratio of gluconic acid and react at a temperature of 130°C 4h, and then the temperature was raised to 190°C, and reacted for 8 hours to obtain a water-soluble imidazoline gluconate mixture.

[0049] 2) Mix 10 parts by weight of the water-soluble imidazoline gluconate mixture obtained in 1), with 3 parts by weight of zinc citrate, 6 parts by weight of sodium borate, 3 parts by weight of polyaspartic acid, 2 parts by weight Sodium tungstate, 6 parts by weight of sodium molybdate, 4 parts by weight of zinc acetate, 2 parts by weight of ethylenediamine tetramethylene phosphoric acid, 1 part by weight of pentasodium diethylenetriaminepentamethylene phos...

Embodiment 3

[0054] 1. Preparation of open-type high-oxygen circulating cooling water corrosion inhibitor and detection of corrosion inhibition effect:

[0055] 1) Catalyze reaction of hydroxyethylethylenediamine and ethylene oxide at a molar ratio of 1:1 under alkaline conditions at 70°C for 2 hours. After the reaction is completed, add gluconic acid in a molar ratio and react at a temperature of 140°C 4h, and then the temperature was raised to 200°C, and reacted for 8 hours to obtain a water-soluble imidazoline gluconate mixture.

[0056] 2) Mix 8 parts by weight of the water-soluble imidazoline gluconate mixture obtained in 1), with 2 parts by weight of zinc citrate, 7 parts by weight of sodium borate, 2 parts by weight of polyaspartic acid, 2 parts by weight Sodium tungstate, 5 parts by weight of sodium molybdate, 3 parts by weight of zinc acetate, 1 part by weight of ethylenediaminetetramethylene phosphoric acid, 2 parts by weight of pentasodium diethylenetriaminepentamethylene phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com