Preparation method of well site environment-friendly toilet degradation product and method for treating water-based solid waste

A degradable and biological treatment technology, which is applied in the field of water-based solid waste treatment and the preparation of degraded products of well-site environmental protection toilets, can solve the problems of high disposal costs, high transportation costs, increased safety and environmental protection risks, and achieves reduction in use and transfer. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In an exemplary embodiment of the present invention, the preparation method of the degradation product of the environmental protection toilet at the well site includes the steps of: treating the domestic wastewater and human feces produced by the environmental protection toilet at the well site with biological agents, and then filtering and drying to a water content of 30-55% , to obtain the degradation product of the well site environmental protection toilet. Wherein, the biological agent is Bacillus velezensis B3-4 or its bacterial suspension or its culture solution or its fermentation product, and the degradation product of the environmental protection toilet at the well site may include 40-62% wt of organic matter, 0.5- 1.0%wt nitrogen, 1.2-1.5%wt phosphorus, 0.8-1.2%wt potassium. The degraded products of environmental protection toilets on the well site contain nutrients such as organic matter, nitrogen, phosphorus, and potassium. They are high-quality raw material...

example 1

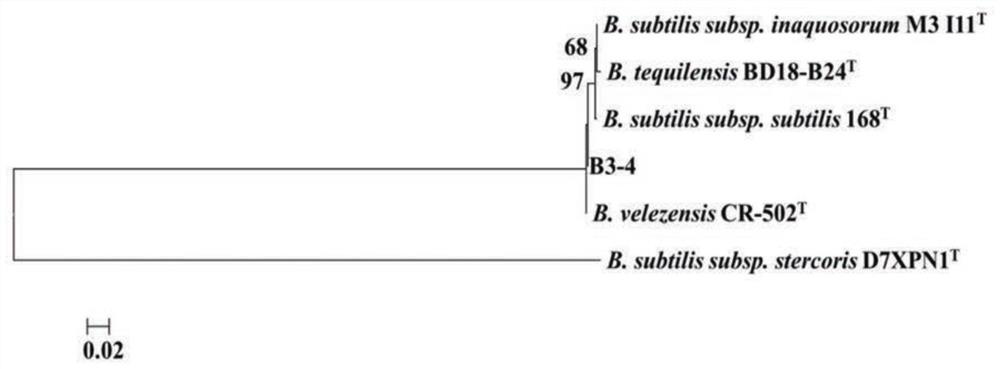

[0037] (1) Isolation, purification and preservation of Bacillus velezensis B3-4 (referred to as "strain B3-4")

[0038] The collected human feces samples were cryopreserved and brought back to the laboratory. Take 5 g of feces samples, use the gradient dilution method, spread on the beef extract peptone medium, and incubate at a constant temperature of 30°C. After the colonies grew out, the colonies with different shapes were selected from the plate and streaked on the beef extract peptone plate. After culturing for 16 hours, pick a ring for repeated streak culture, combined with microscopic observation, until purification. The purified strains were stored in the test tube slant medium of beef extract peptone medium.

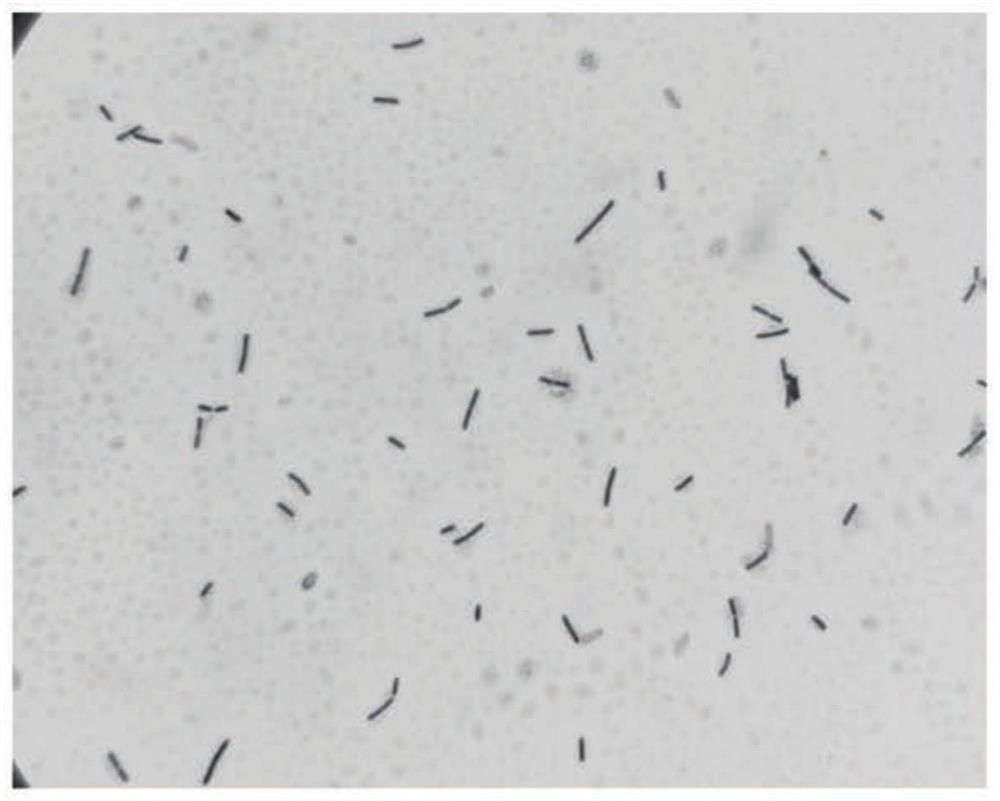

[0039] As shown in Figure 1, the isolated and purified strain B3-4 obtained in this example was cultured on beef extract peptone medium, and after 48 hours of culture, the colony was round, white, with a diameter of 0.5-1 mm, irregular edges, flat and moist. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com