Waterproof construction method of multi-layer combined type expansion joint of underground structure

A technology of underground structure and construction method, applied in the layout of foundation structure joints or in the field of structure, can solve the problems of temporary solution, high cost of plugging, failure to fundamentally eliminate leakage, etc., achieve wide application range, avoid Leakage repair cost, waterproof quality and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

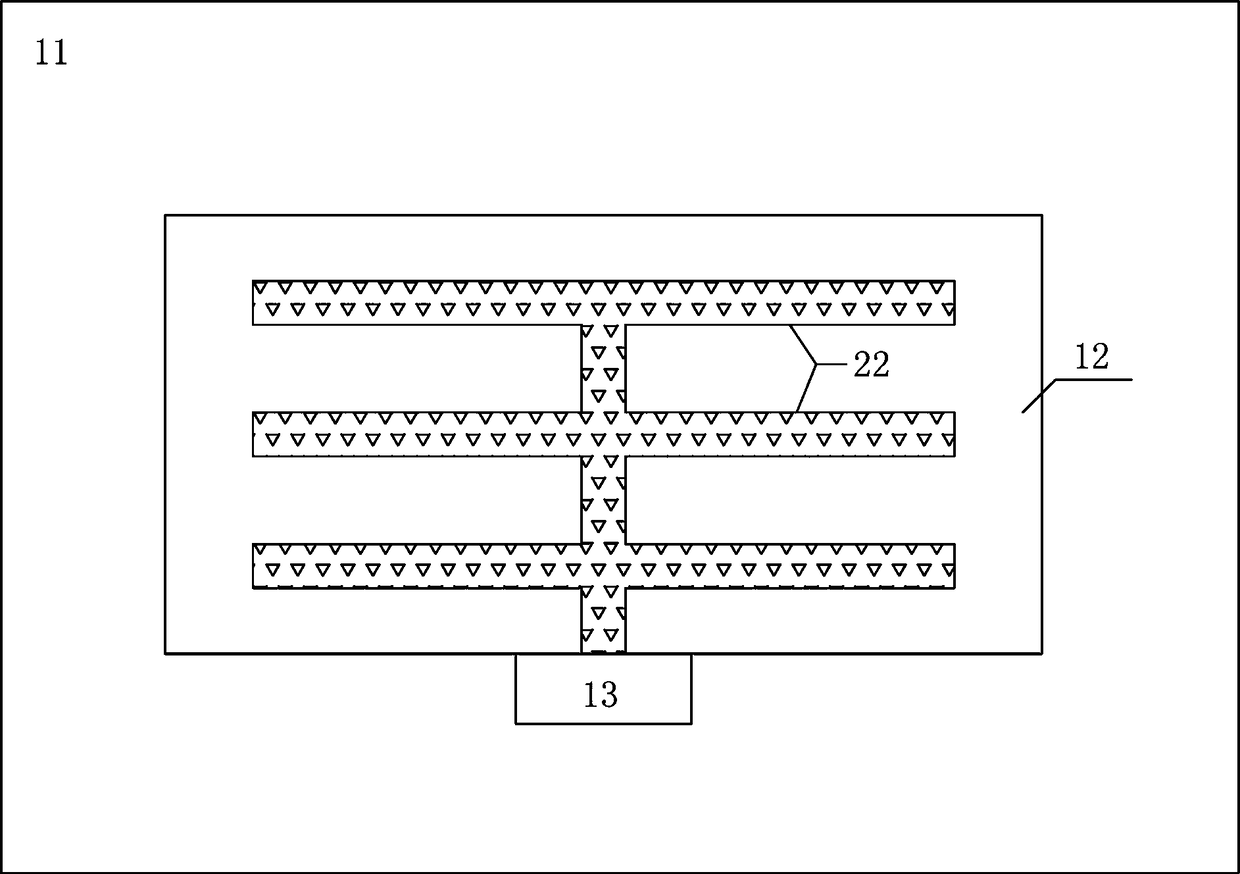

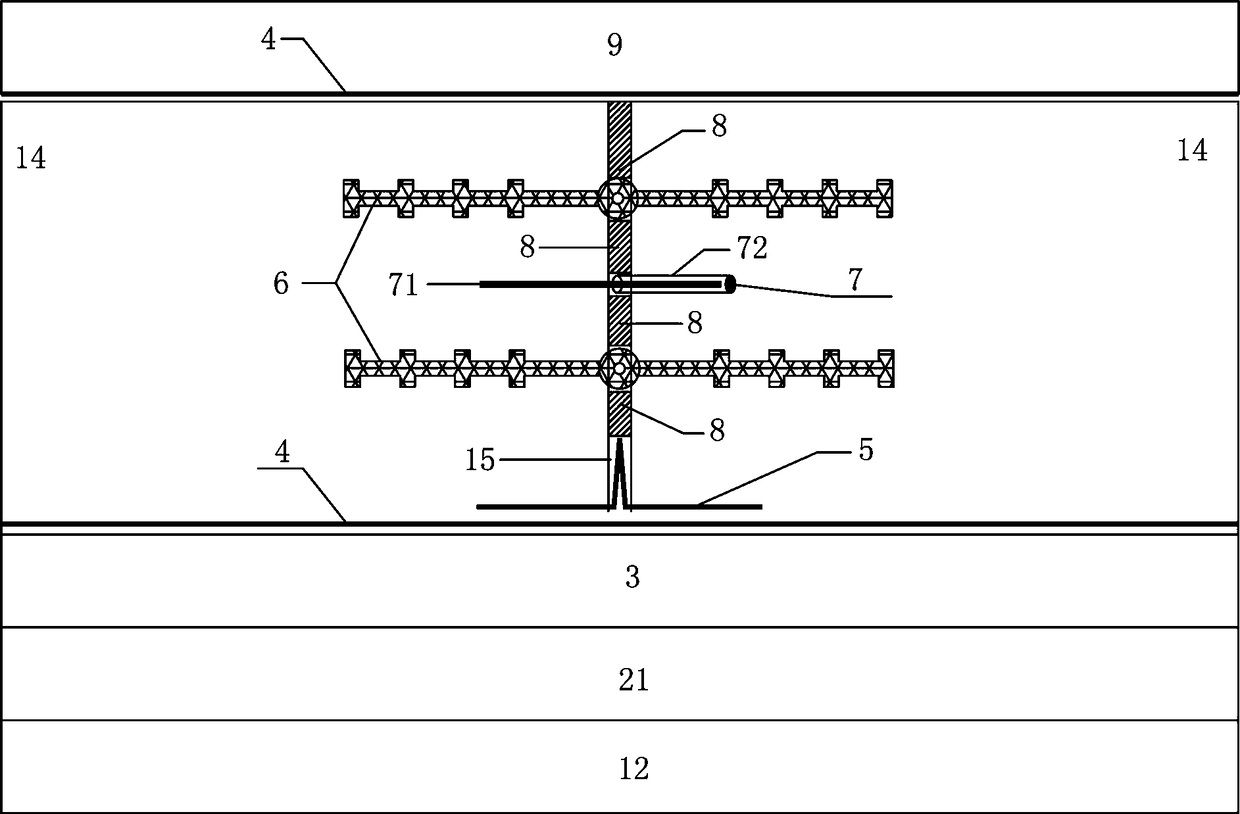

[0033] A multi-layer combined expansion joint waterproof construction method for underground structures, such as figure 1 and figure 2 As shown, implement in sequence as follows:

[0034] a. Excavate the blind ditch layer: if figure 1 As shown: the underground structure 11 is excavated to the foundation trench surface 12, and a blind ditch layer 21 with a depth of not less than 30 cm is excavated on the foundation trench surface 12, and a blind ditch 22 is buried in the blind ditch layer 21 as a drainage ditch, and the blind ditch 22 Including at least one horizontal blind ditch 22 and at least one longitudinal blind ditch 22, the horizontal blind ditch 22 is parallel to each other, the longitudinal blind ditch 22 is parallel to each other, and the horizontal blind ditch 22 and the longitudinal blind ditch 22 are connected to each other , at least one blind ditch 22 flows into the water inlet of the water pump house 13; there is no special requirement for the setting form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com