Anti-collision dustproof novel magnetic ABS gear ring

A new type of ABS ring gear technology, applied in the field of ABS ring gear, can solve the problems of increased manufacturing cost, deformation, and high requirements for magnetic ring surface protection, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

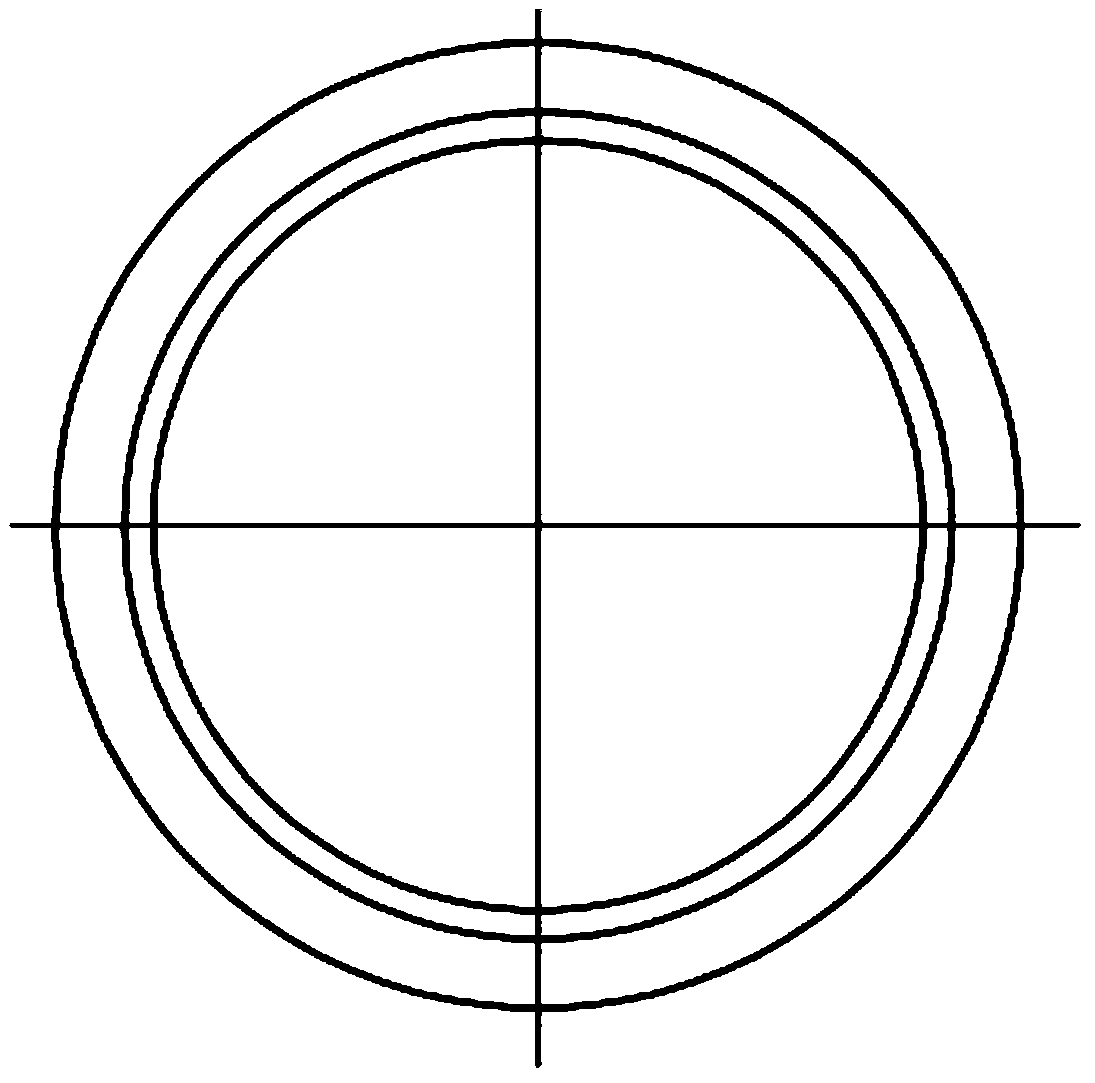

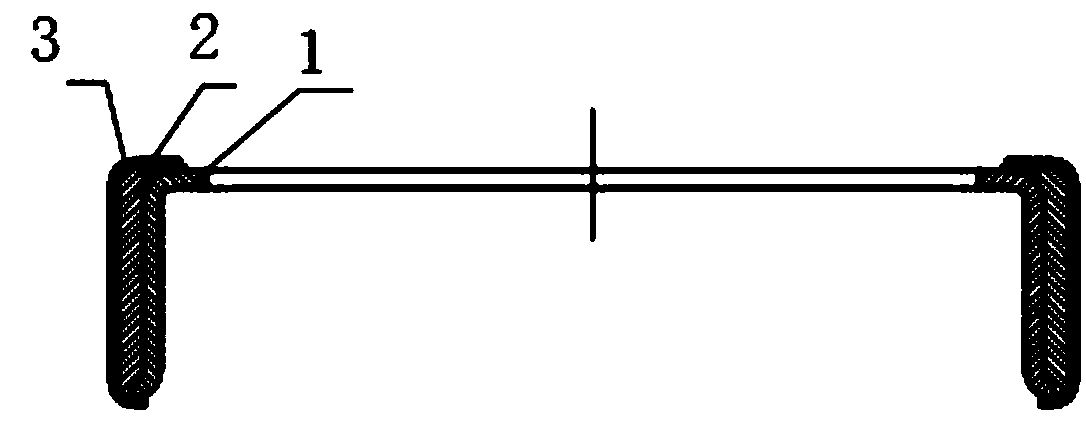

[0014] Such as figure 1 and figure 2 As shown, a new type of magnetic ABS ring gear with anti-collision and dust resistance includes a ring gear body and a magnetic rubber 2 arranged on the ring gear body. Between the ring gear body and the magnetic rubber 2 there is a Magnetic rubber 2 and an inner metal bracket 1 that is isolated from the ring gear body. The magnetic rubber 2 is provided with metal protection for protecting the magnetic rubber 2 from external force damage to the surface of the magnetic rubber 2 and causing poor signal caused by dust pollution. Circle 3.

[0015] Add a layer of metal protective ring 3 on the outer surface of the original magnetic ABS ring, which is beneficial to the protection of the metal material with high hardness and excellent magnetic conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com