Kitchen ventilator with oil-smoke separation device and noise reduction device and noise reduction method

A technology of oil fume separation and range hood, which is applied in the direction of oil fume removal, heating methods, lighting and heating equipment, etc., which can solve the problems of increasing the difficulty of noise reduction in three-dimensional space, inability to adapt to high-order sound, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

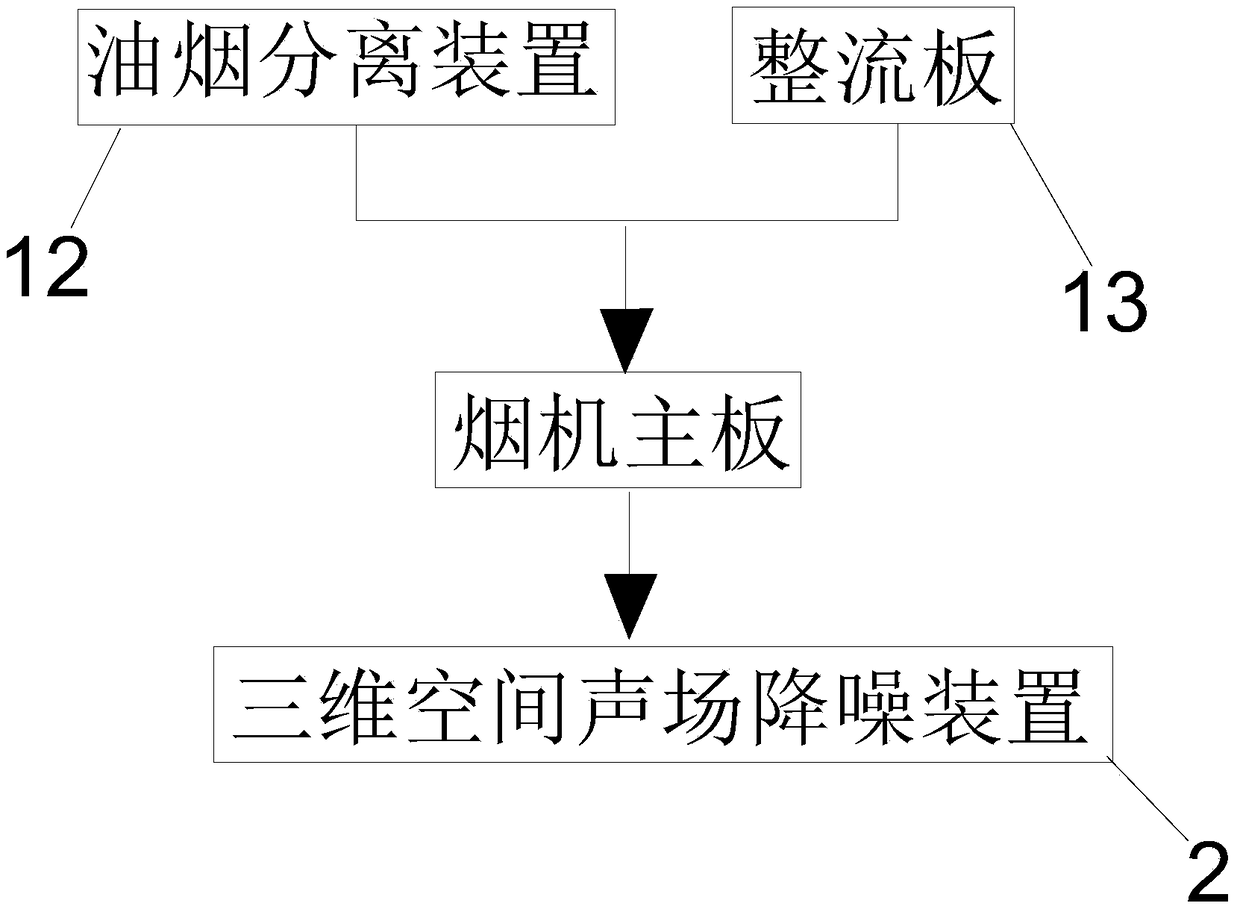

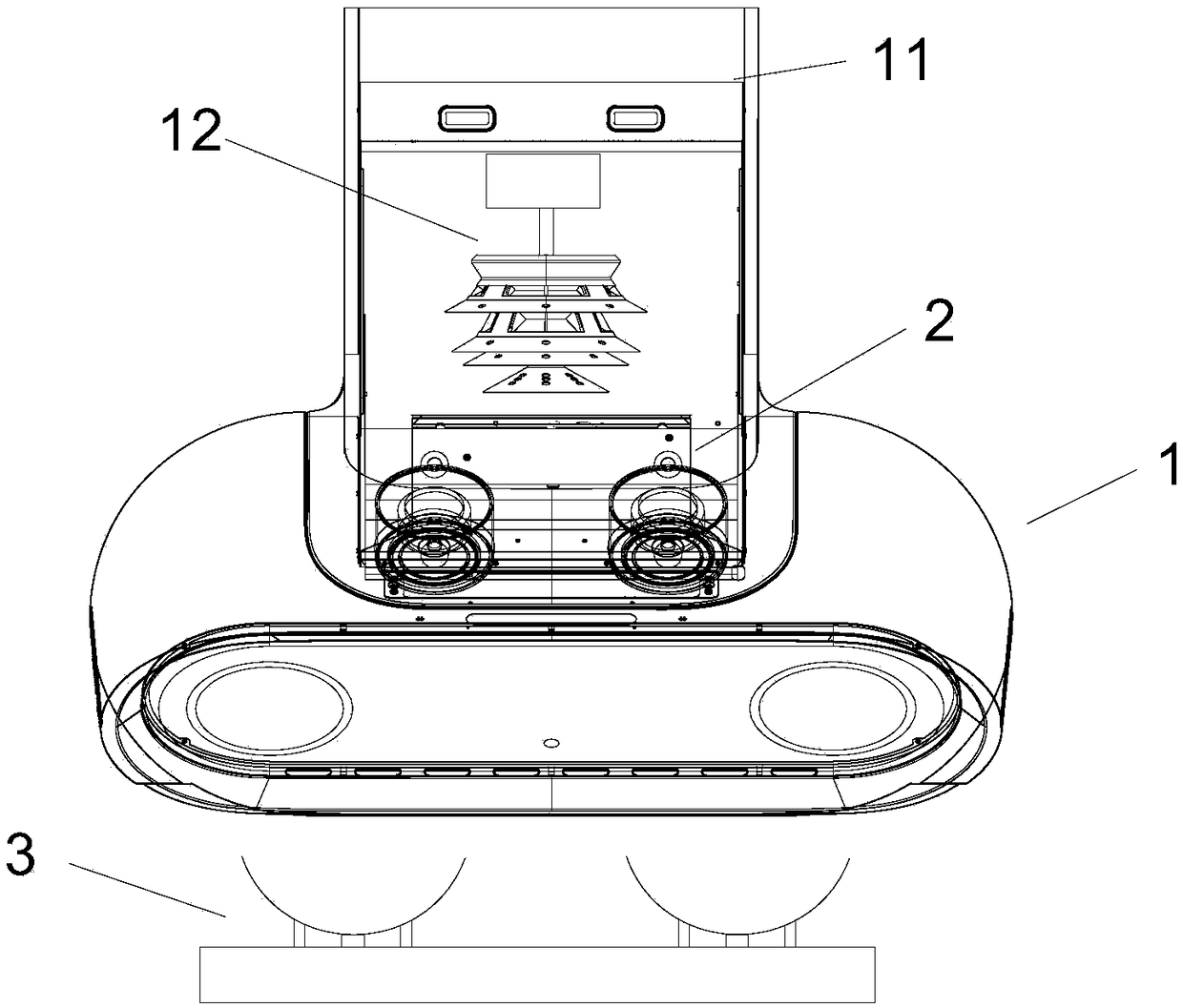

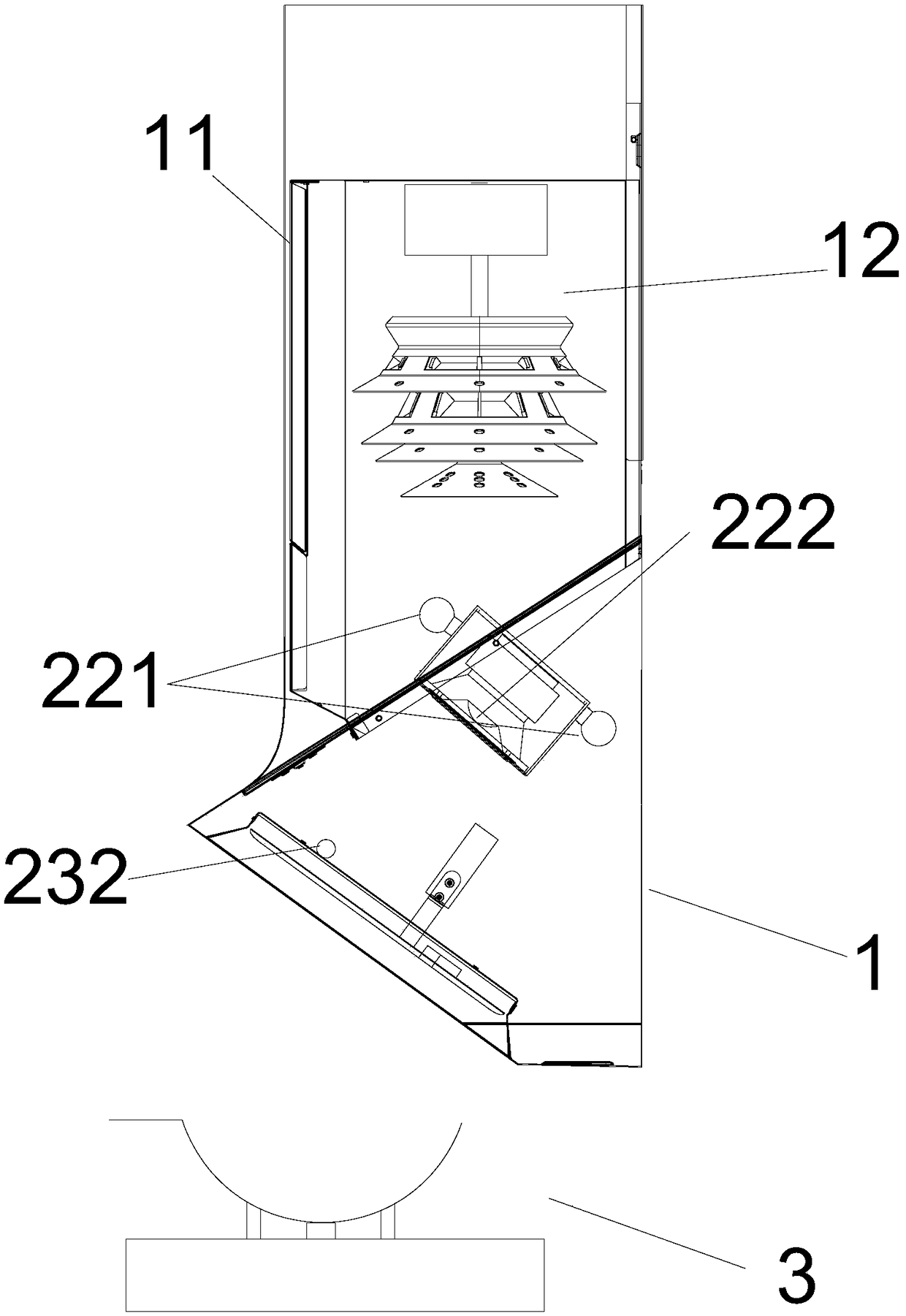

[0096] A range hood with an oil fume separation device 12 and a noise reduction device, such as Figures 1 to 10 As shown, there are a hood main body 1, a three-dimensional sound field noise reduction device 2 for active noise reduction, and an oil fume separation device 12 for absorbing and separating oil fume particles. The three-dimensional sound field noise reduction device 2 is assembled on the hood main body 1 Inside, the oil fume separation device 12 is driven and assembled inside the main body 1 of the hood. The hood main body 1 is provided with a hood main board to control the operation of the range hood, and the hood main board is electrically connected to the three-dimensional sound field noise reduction device 2 .

[0097] The main board of the hood detects the working state of the main body of the hood 1. When the working state is higher than the threshold value, the main board of the hood transmits an indication signal to the three-dimensional sound field noise r...

Embodiment 2

[0122] A range hood with an oil fume separation device 12 and a noise reduction device, other features are the same as in Embodiment 1, the difference is that the outer surface of the low-damping bellows 11 of this embodiment is equipped with a foam board.

[0123] It should be noted that the outer surface of the low-damping bellows 11 of the present invention may be equipped with a foam board, or any one of a foam board or a rubber board.

[0124] The role of the foam board, foam board or rubber board is to block the noise from spreading to the outside, thereby reducing the noise level.

[0125] Compared with Embodiment 1, the noise reduction effect of the range hood of this embodiment is better.

Embodiment 3

[0127] A range hood with an oil fume separation device 12 and a noise reduction device, other features are the same as in Embodiment 1, the difference is that the oil fume separation device 12 of this embodiment is located in the air inlet formed by a filter screen 115 and a low damping bellows 11 The inside of the fully enclosed structure and the three-dimensional sound field noise reduction unit 22 is located outside the fully enclosed structure, such as Figure 11 A in and Figure 11 Shown in B.

[0128] Compared with Embodiment 1, the seamless all-enclosed structure of this embodiment can prevent noise sound waves from propagating to the outside, and better improve the noise reduction effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com