Graded broken stone repeated load experiment elastoplasticity yield point stress determining method

A technology of graded crushed stone and load test, applied in the direction of applying repeated force/pulsation force to test material strength, strength characteristics, measuring devices, etc., can solve the lack of instructions and guidance, unclear status, and evaluation of long-term performance of structures and forecasting, etc., to achieve the effects of clear representative meaning, convenient test method and parameter acquisition method, and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

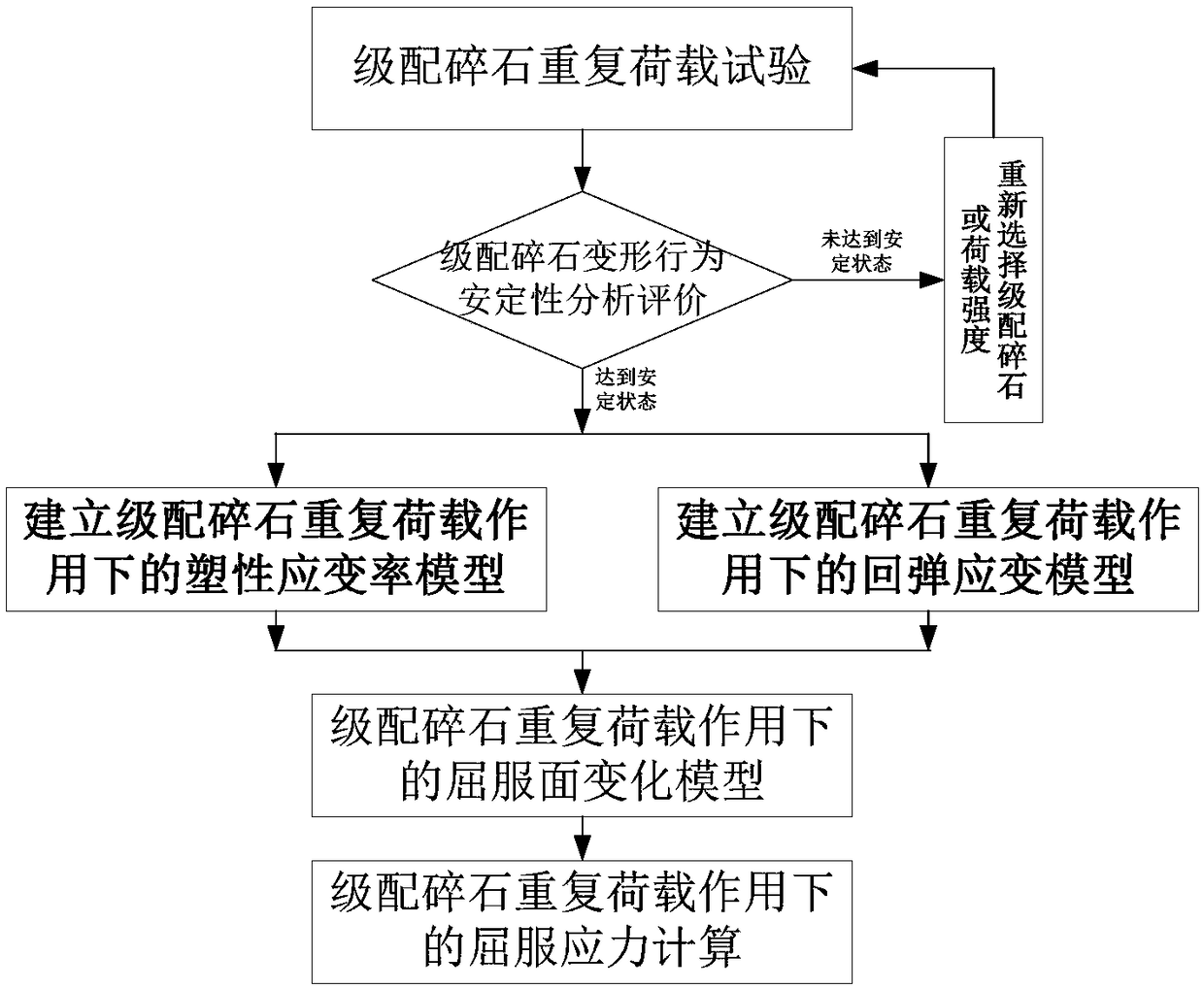

Method used

Image

Examples

Embodiment

[0053] Taking the graded gravel with interlocking dense skeleton structure as an example, the confining pressure is 10kPa, the axial load strength is 80kPa, 160kPa, 240kPa and 320kPa respectively, and 20000 repeated load tests are carried out respectively.

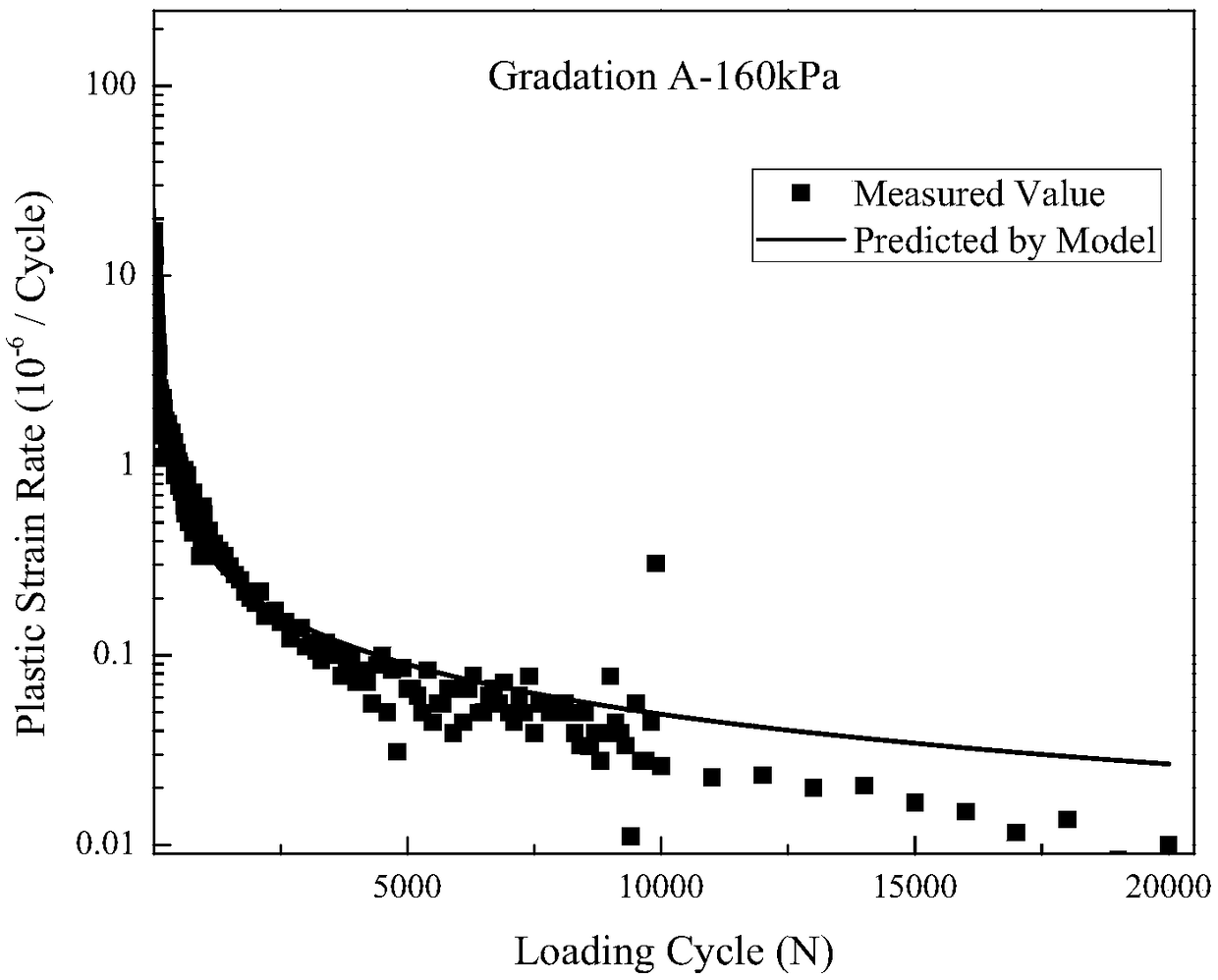

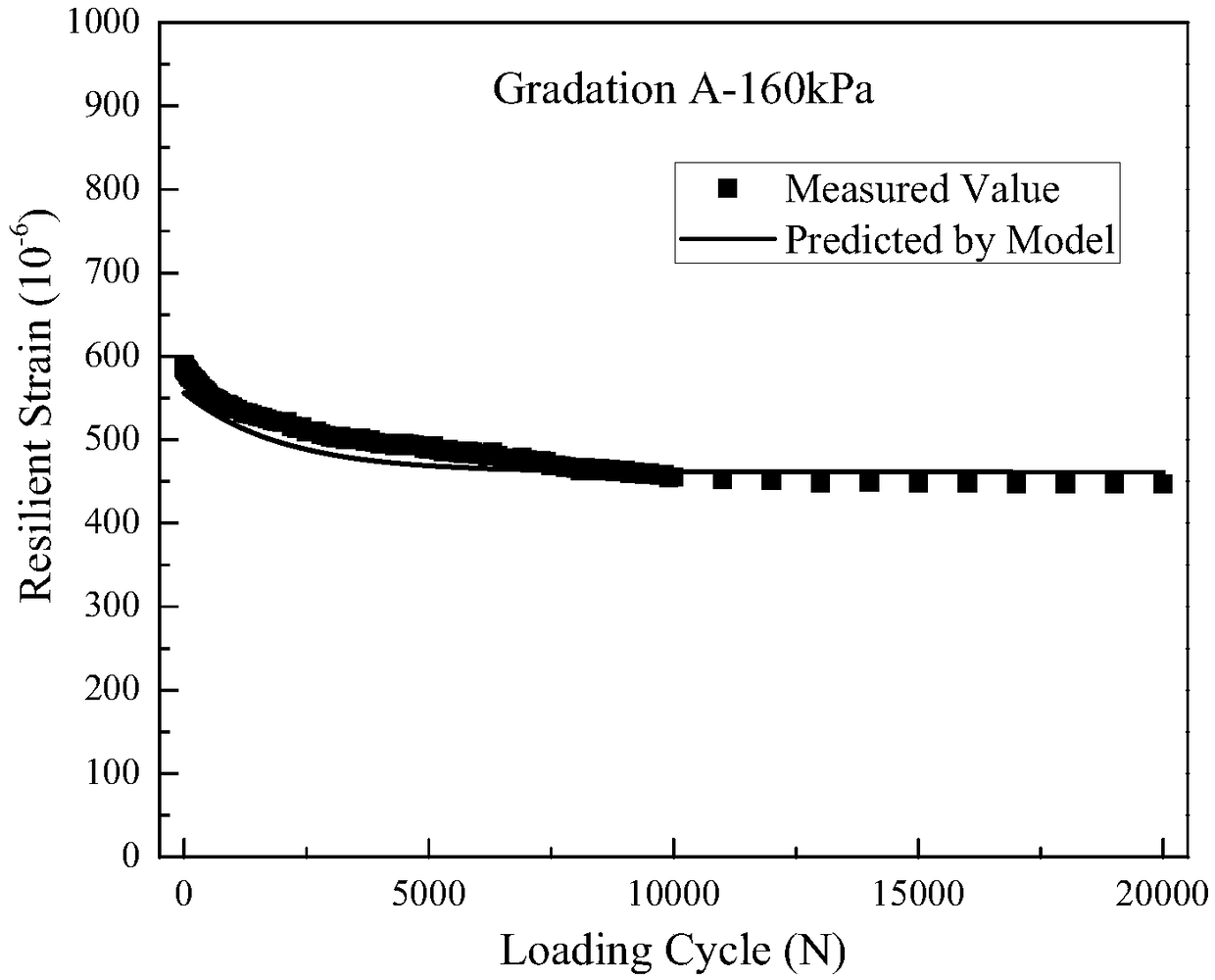

[0054] According to the calculation method of plastic strain rate and springback strain, the plastic strain rate and springback strain under different load intensities and load times are calculated.

[0055] The plastic strain is judged according to the stability, and the plastic cumulative strain during the period of 3000 to 5000 loads is judged. The judgment results meet the stability requirements, indicating that the graded crushed stone will be in a stable state after a certain number of repeated loads.

[0056] The calculation models of plastic strain rate and springback strain under different load intensities and load times are established. In an embodiment, the calculation model of the plastic strain rate is: The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com