Lithium ion battery consistency screening and grouping method based on internal characteristics

A lithium-ion battery and grouping method technology, which is applied in the field of electric vehicle battery production and management, can solve problems such as poor screening and grouping methods, and achieve the effects of reducing inconsistency, improving safety, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

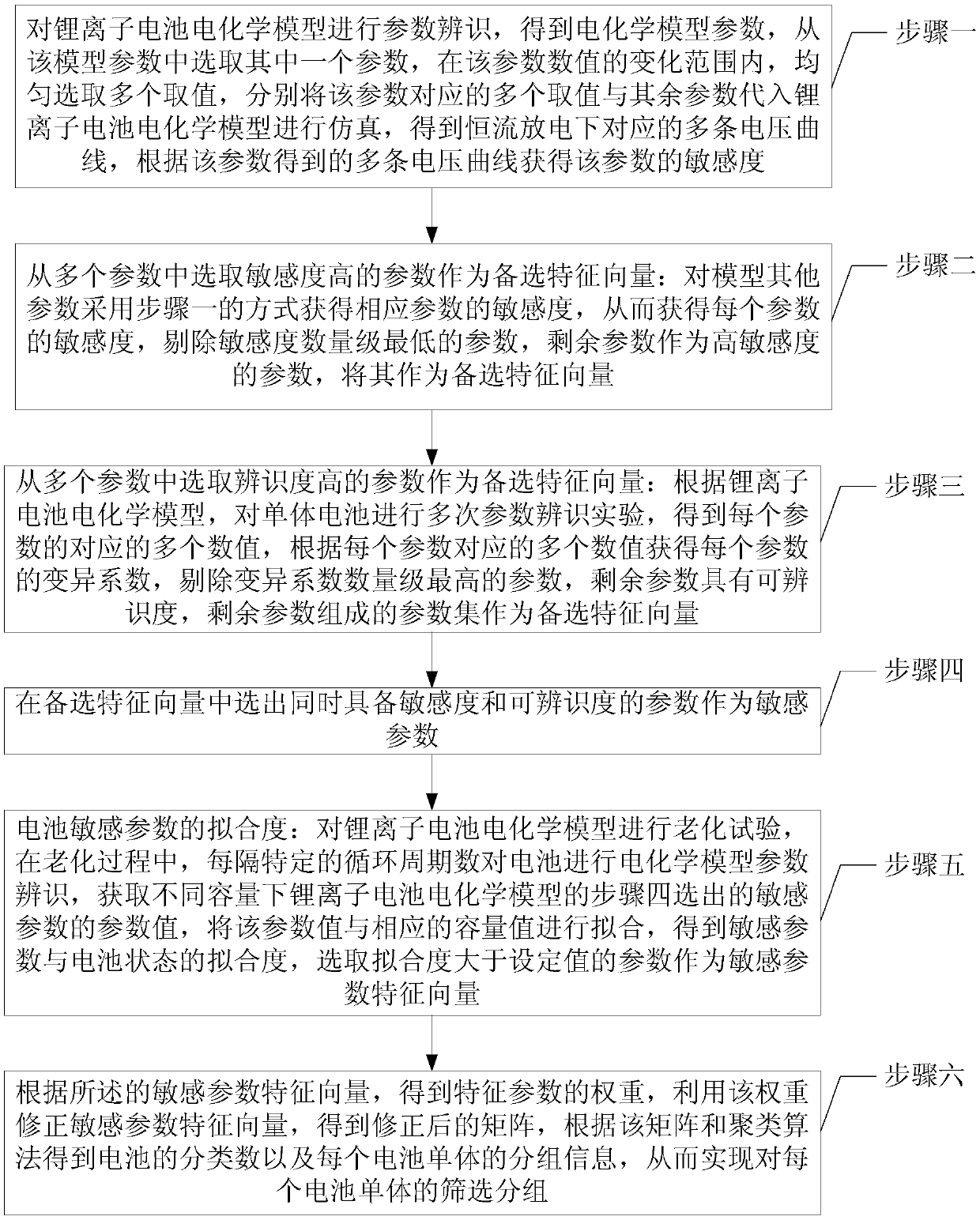

[0020] Specific implementation mode one: refer to figure 1 value Figure 4 Specifically explain this embodiment, the lithium-ion battery consistency screening and grouping method based on internal characteristics described in this embodiment, the method includes the following steps:

[0021] The method comprises the steps of:

[0022] Step 1: Carry out parameter identification on the electrochemical model of the lithium-ion battery to obtain the electrochemical model parameters, select one of the parameters from the model parameters, and select multiple values evenly within the variation range of the parameter value, and respectively select the parameter The corresponding multiple values and other parameters are substituted into the electrochemical model of the lithium-ion battery for simulation, and multiple voltage curves corresponding to constant current discharge are obtained, and the sensitivity of the parameter is obtained according to the multiple voltage curves ob...

specific Embodiment approach 2

[0087] Specific embodiment 2: This embodiment is to further explain the lithium-ion battery consistency screening and grouping method based on internal characteristics described in specific embodiment 1. In this embodiment, in step 1, the sensitivity of each parameter is obtained. for:

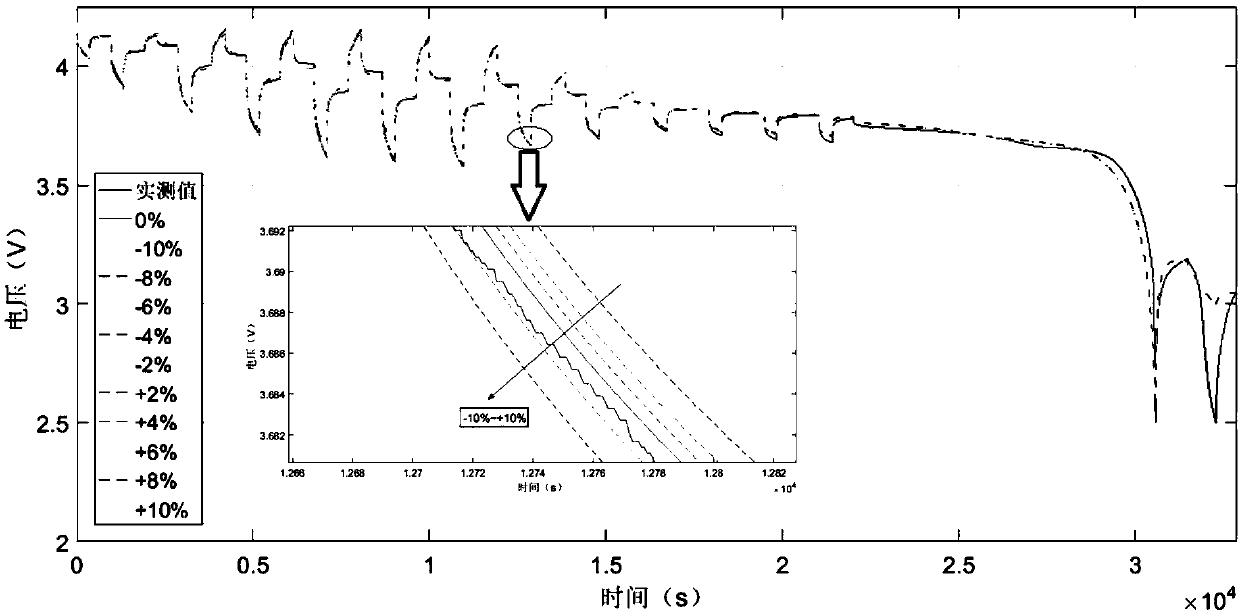

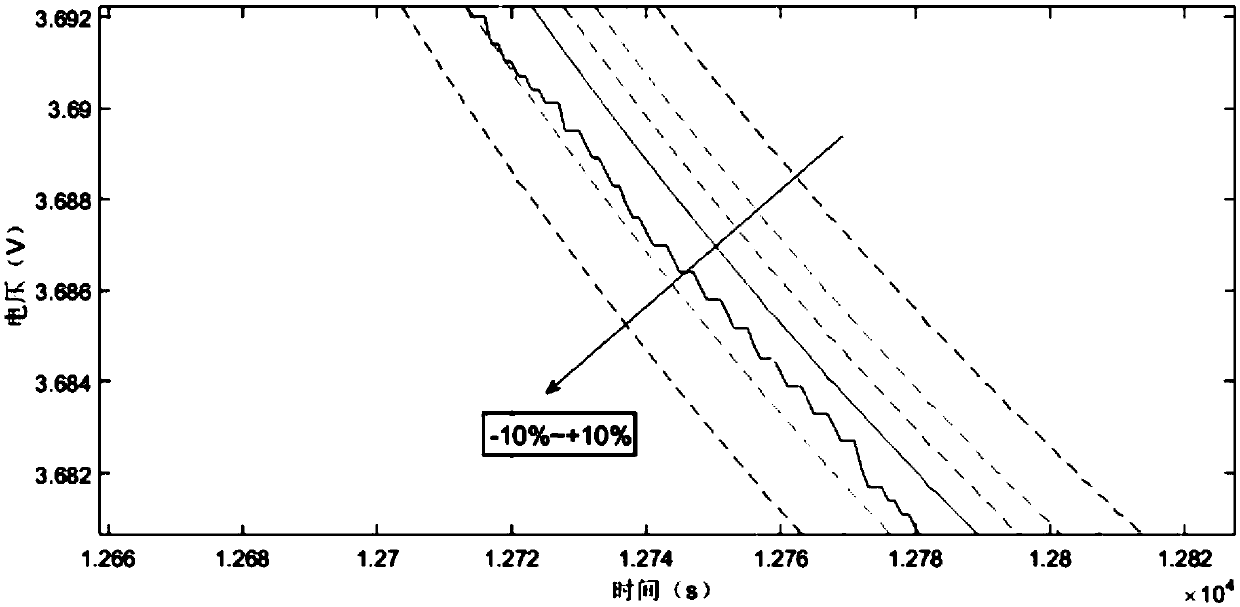

[0088] From the multiple voltage curves obtained by each parameter, N time points are evenly selected, and each time point corresponds to multiple voltage values. Value and the voltage corresponding to a certain value of this parameter at a certain time point, the sensitivity of obtaining this parameter is:

[0089]

[0090] In the formula, σ j Represents the sensitivity of the jth model parameter of the battery, i represents the ith value of the model parameter within the range of ±10%, n represents the number of sampling points for the voltage curve family, the maximum value is N, V nij Indicates the battery terminal voltage corresponding to the i-th value of the j-th model parameter at...

specific Embodiment approach 3

[0091] Specific embodiment three: This embodiment is to further explain the lithium-ion battery consistency screening and grouping method based on internal characteristics described in specific embodiment one. In this embodiment, in step three, the coefficient of variation c v The acquisition process is:

[0092] Obtain the mean value and standard deviation of the parameter according to multiple values corresponding to each parameter, and obtain the coefficient of variation c of the parameter according to the mean value of each parameter and the standard deviation of the parameter v for:

[0093]

[0094] In the formula, σ is the standard deviation of multiple values of the same parameter, and μ is the average value of multiple values of the same parameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com