An automatic shrimp-removing robot

A robot and shrimp line technology, which is applied in the fields of shrimp/lobster processing, slaughtering, food science, etc., can solve the problems of cumbersome process, affecting the taste of eating, and the inability to complete the work of removing shrimp lines automatically, so as to achieve a wide range of control and improve The effect of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

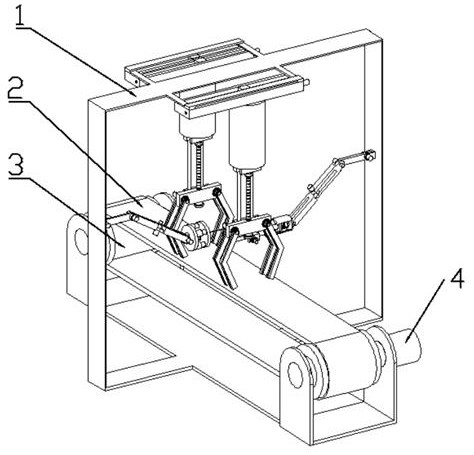

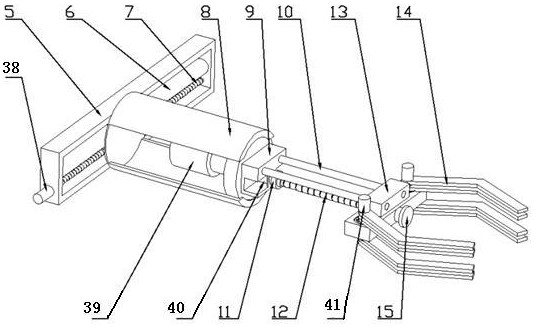

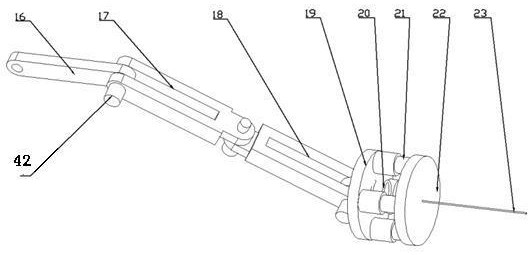

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4Shown, a kind of robot that automatically removes shrimp line is characterized in that: comprise main frame 1, sprocket shaft 3, belt 2, first stepping motor 4 grasping part, pick-up part, thread lifting part; Grabbing part comprises: Stepping motor 4, screw rack 5, translation guide rail 6, translation screw rod 7, rotating motor rack 8, rotation screw seat 9, claw telescopic guide rail 10, coupling 11, claw telescopic screw rod 12, claw seat 13. Claw part 14, screw sleeve 15, second stepping motor 38, third stepping motor 39, fourth stepping motor 40, fifth stepping motor 41; thread take-up part includes: sixth stepping motor 42 , needle connecting rod 16, the first up and down adjustment rod 17, the first left and right adjustment rod 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com