A green vegetable processing automatic processing equipment

A vegetable processing and processing equipment technology, applied in the field of green vegetable processing automation processing equipment, can solve the problems of increasing labor force usage, unable to meet vegetable classification processing, low degree of automation, etc., and achieves improved efficiency, uniform support, and improved practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

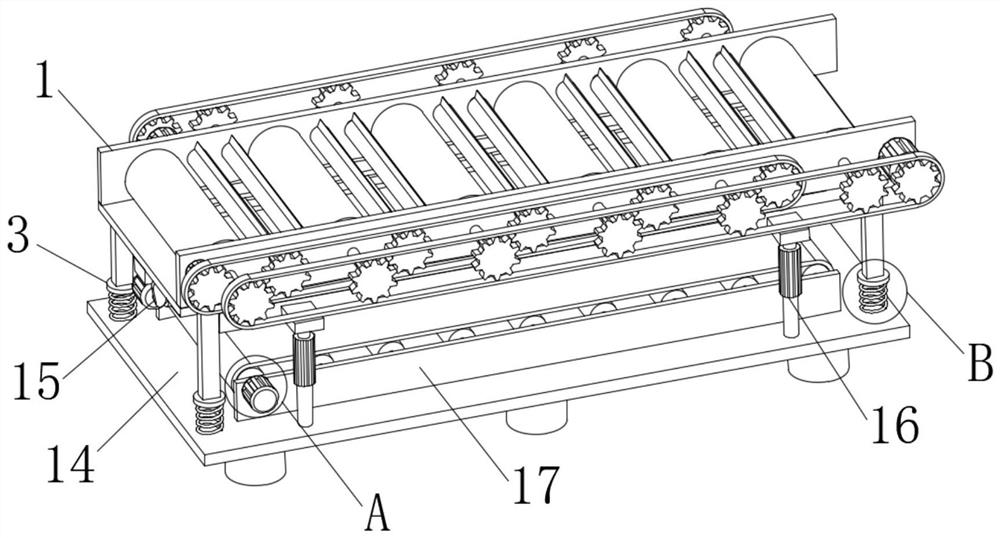

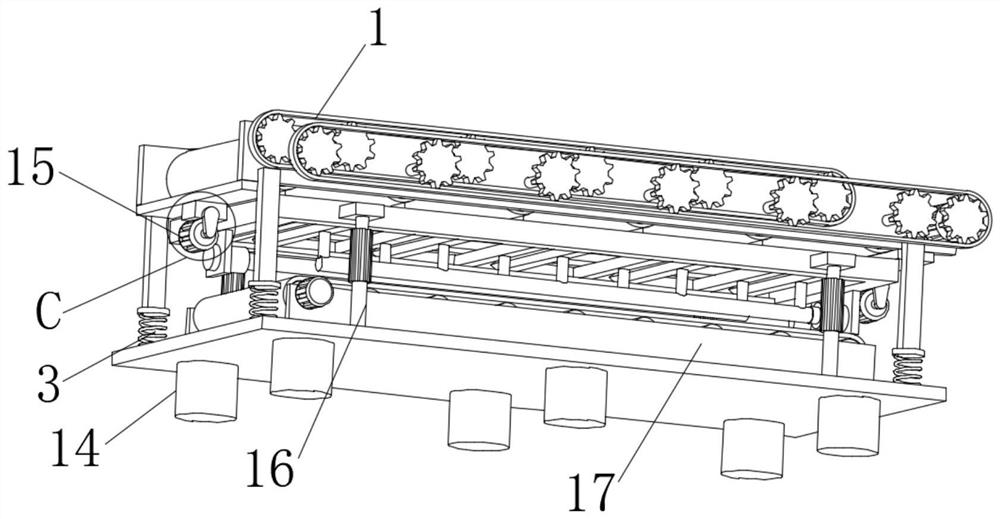

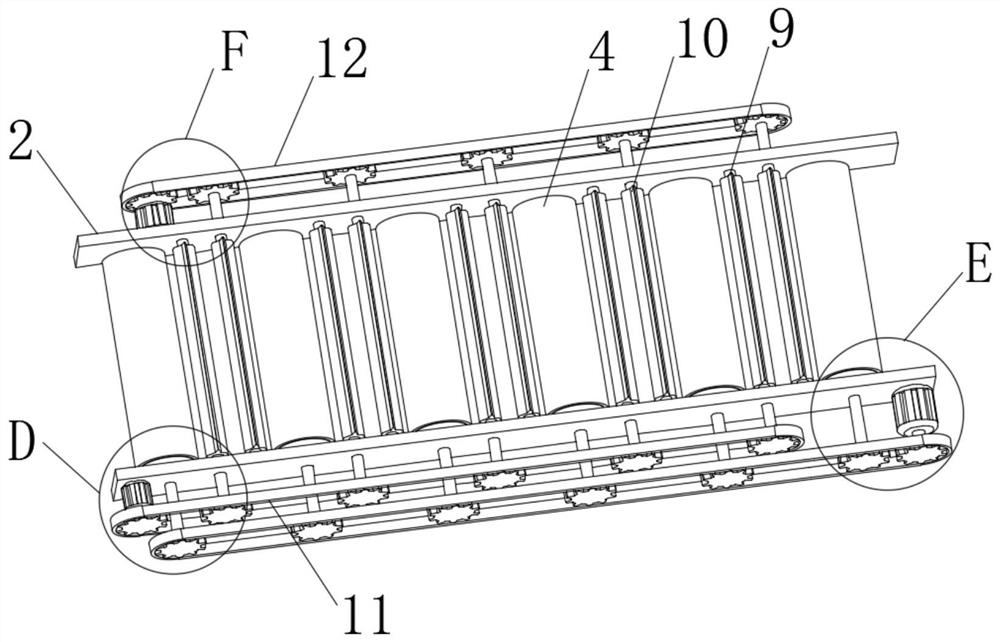

[0037] Example 1, see Figure 1-4 , the present invention provides a technical solution: an automatic processing equipment for green vegetables, including a conveying device 1 and a support table 14, the conveying device 1 includes a supporting plate 2, a buffer 3, a conveying roller 4, a first gear 5, The first gear chain 6, the second gear 7, the transmission motor 8, the first shearing roller 9, the second shearing roller 10, the first driving member 11, the second driving member 12 and the first shearing tool 13, the The outer side of the bottom of the support plate 2 is fixed to the support platform 14 through the buffer member 3, and the two ends of the transmission roller 4 are respectively connected to the support plate 2 through bearings, and one end of the transmission roller 4 passes through the support plate 2 and the first gear 5 Fixed, the first gear 5 is connected to the second gear 7 through the first gear chain 6, the second gear 7 is fixed to the output shaft...

Embodiment 2

[0041] Example 2, see Figure 5 , the first drive member 11 includes a first drive motor 18, a third gear 19, a second gear chain 20 and a fourth gear 21, and one end of the first shear roller 9 passes through the support plate 2 and the third gear 19 is fixed, the third gear 19 is meshed with the fourth gear 21 through the second gear chain 20, and the fourth gear 21 is fixed with the output shaft of the first drive motor 18, and the first drive motor 18 is fixed on the support The outer side of the plate 2 can drive the first shearing roller 9 to rotate through the first driving member 11 .

Embodiment 3

[0042] Example 3, see Figure 6 , the second drive member 12 includes a second drive motor 22, a fifth gear 23, a third gear chain 24 and a sixth gear 25, and the end of the second shearing roller 10 away from the second gear chain 20 passes through the support The plate 2 is fixed with the fifth gear 23, and the fifth gear 23 is meshed with the sixth gear 25 through the third gear chain 24, and the sixth gear 25 is fixed with the output shaft of the second driving motor 22, and the second The driving motor 22 is fixed on the supporting plate 2 at the end of the conveying roller 4 away from the first driving motor 18 , and the second driving member 12 can drive the rotation of the second shearing roller 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com