Median bundle core and packaging pipe

A technology for packaging tubes and beam cores, which is applied in the field of packaging tubes and can solve problems such as the use of middle beam cores alone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

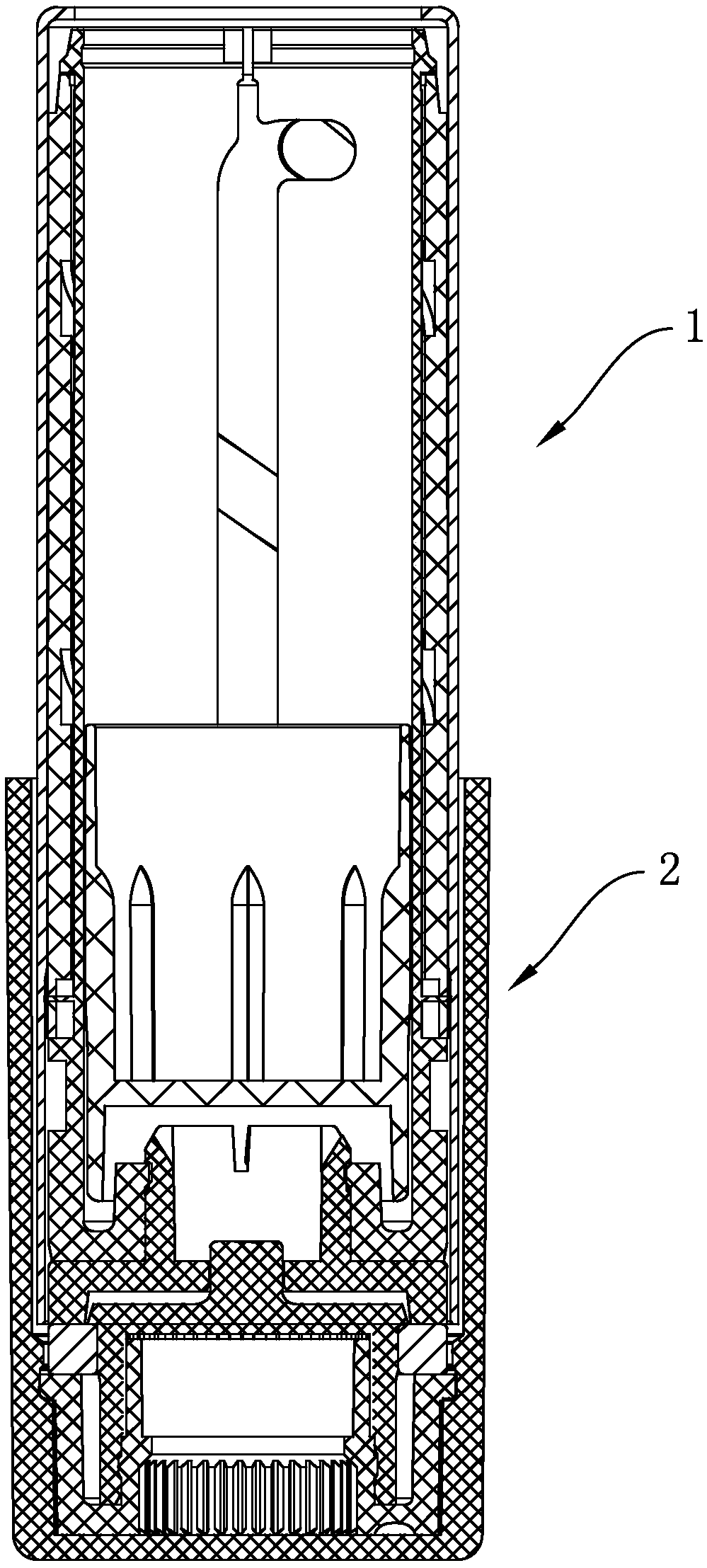

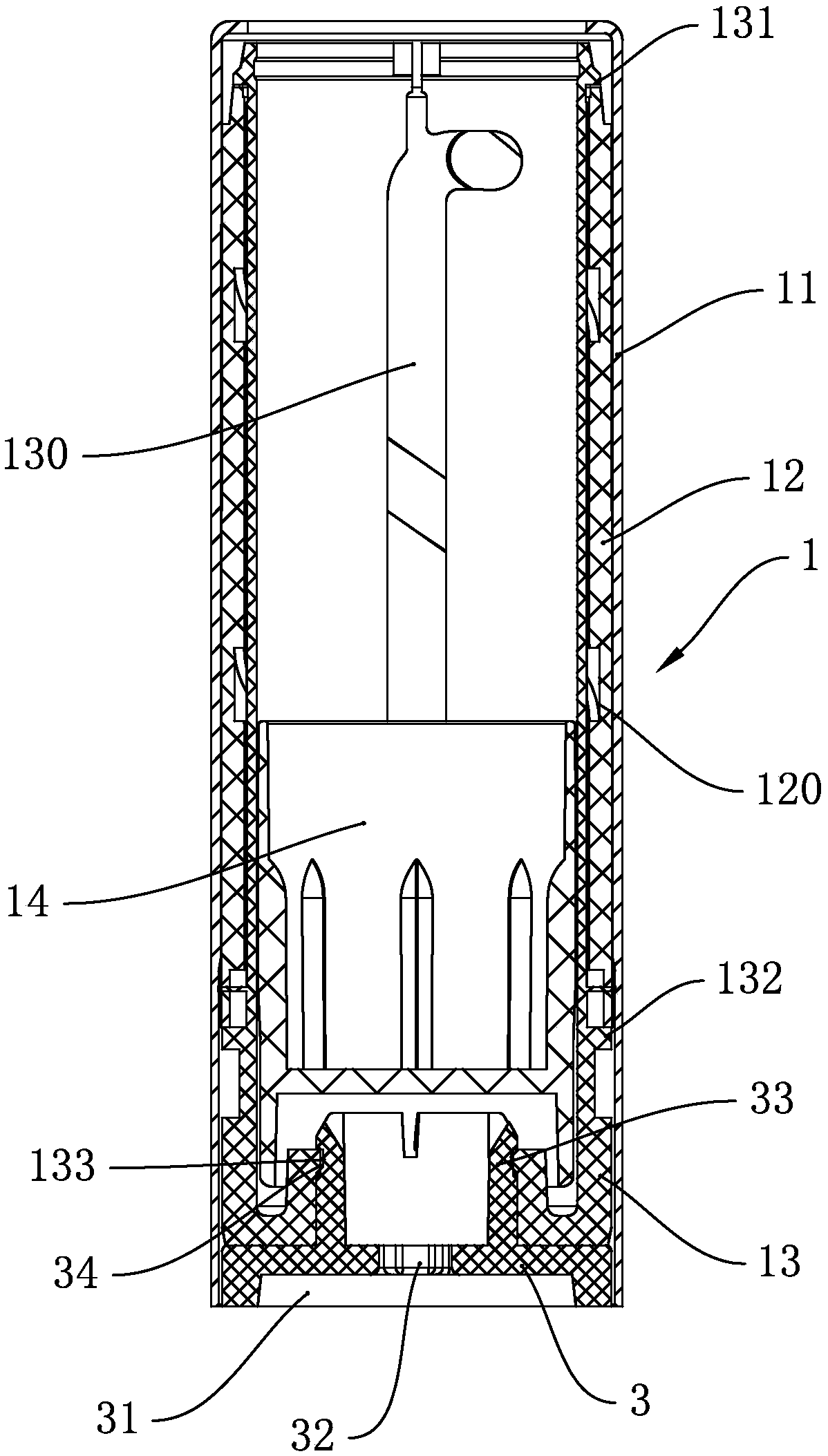

[0033] Such as figure 1 As shown, a packaging tube includes a center beam core 1 and a base 2 , the bottom of the center beam core 1 is inserted into the inner cavity of the base 2 , and the top of the base 2 is exposed. A cover (not shown in the figure) is generally provided on the top, and the cover cooperates with the base 2 to form a cavity surrounding the center beam core 1 .

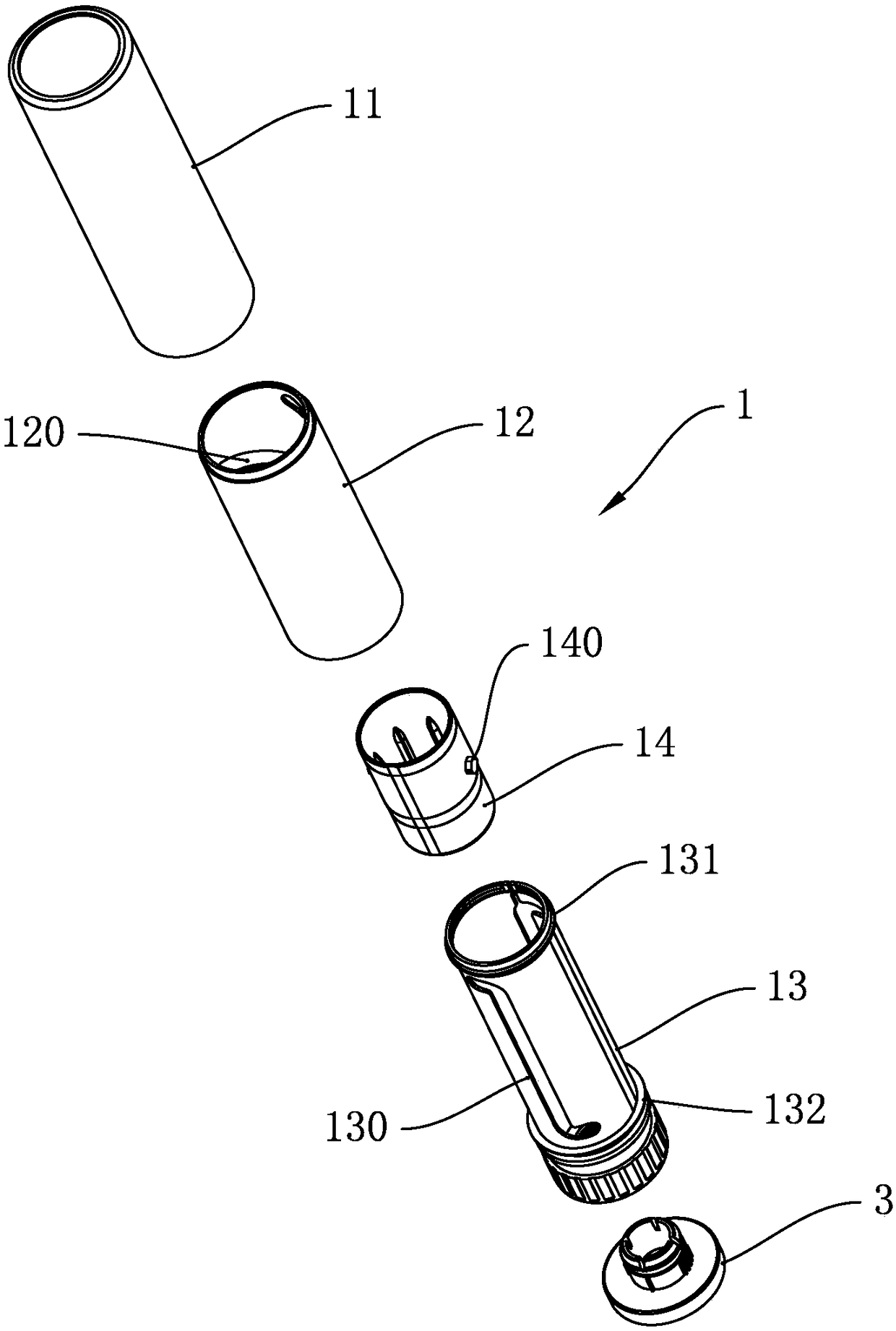

[0034] Such as figure 2 and 3 As shown, the center beam core 1 includes a center beam 11, a helix 12, a fork 13 and a bead 14 coaxially and sequentially threaded. The arranged guide groove 130 and the beads 14 are used to hold the lipstick paste, and the outer surface thereof has a protrusion 140 extending through the guide groove 130 into the spiral groove 120 , and the middle bundle 11 is fixedly connected with the spiral 12 .

[0035] The outer peripheral surface of the fork 13 is provided with limiting steps 131, 132 matched with the end surfaces of both ends of the helix 12, so that it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com