Adjustable-temperature inflatable cushion core and manufacturing method thereof

A manufacturing method and cushion core technology are applied to liquid-filled cushions, other seating furniture, beds, etc., which can solve the problems of insufficient structural strength and stability, inability to meet the needs of use, and only inflatable air cavities, etc., to achieve flexible softness. Hardness and temperature, short production cycle, and easy exhaust storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

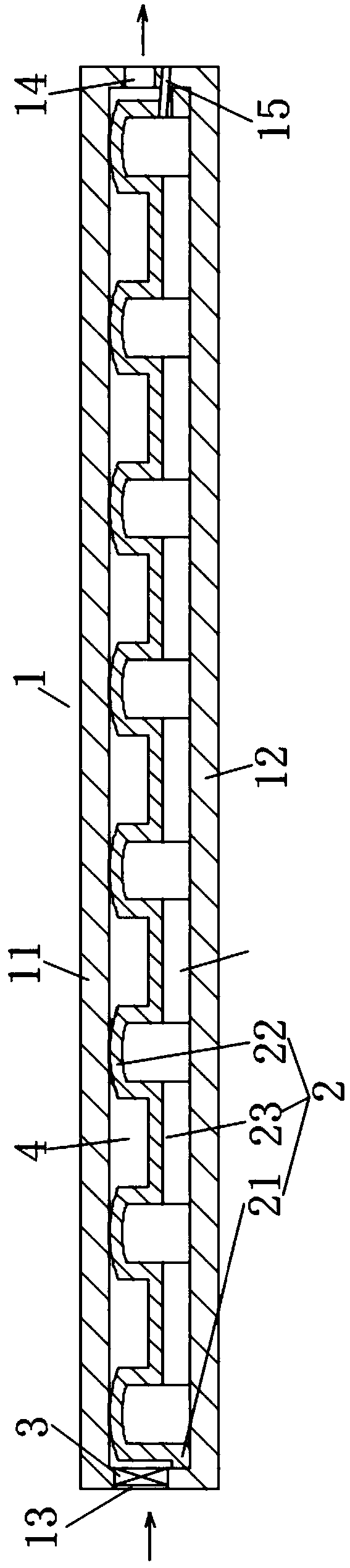

[0037] Embodiment one: if figure 1 As shown, the temperature-adjustable inflatable cushion core of this embodiment includes a cushion body 1, an inflatable inner core 2 and an airflow heating and cooling device 3;

[0038] The above-mentioned pad body 1 is composed of a flexible surface layer 11 and a bottom layer 12, and the surrounding edges of the above-mentioned surface layer 11 and the bottom layer 12 are bonded to each other;

[0039] The above-mentioned inflatable inner core 2 is composed of a flexible inflatable flat layer 21 and a plurality of inflatable columns 22 evenly spaced on one side of the above-mentioned inflatable flat layer 21. The adjacent two above-mentioned inflatable columns 22 are connected through an air channel 23, and the above-mentioned inflatable The column 22 and the air channel 23 are respectively formed by the above-mentioned inflatable flat layer 21 protruding to one side thereof;

[0040] The above-mentioned inflatable flat layer 21 is arran...

Embodiment 2

[0052] Embodiment 2: This embodiment provides a method for manufacturing the temperature-adjustable inflatable cushion core as described in Embodiment 1, including the following steps:

[0053] Step 1, bonding the prefabricated inflatable inner core 2 to the surface layer 11, specifically, bonding the end of each inflatable column 22 of the inflatable inner core 2 away from the inflatable flat layer 21 to the above-mentioned surface layer 11;

[0054] Step 2, bonding the bottom layer 12 to the side of the inflatable flat layer 21 away from the inflatable column 22;

[0055] Step 3, opening a hole on at least one inflation column 22 or air channel 23 close to the edge of the inflation inner core 2 and sealingly installing the inflation port 15;

[0056] Step 4, align the peripheral edges of the surface layer 11 and the bottom layer 12, and make the inflation port 15 pass through the connection between the two, and then bond the surface layer 11 and the bottom layer 12 to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com