Centrifugal solid-liquid separator

A solid-liquid separator, centrifugal technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of low separation efficiency, solid residues cannot be sent out in time, and the separator cannot operate continuously, etc. Wide range of applications and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

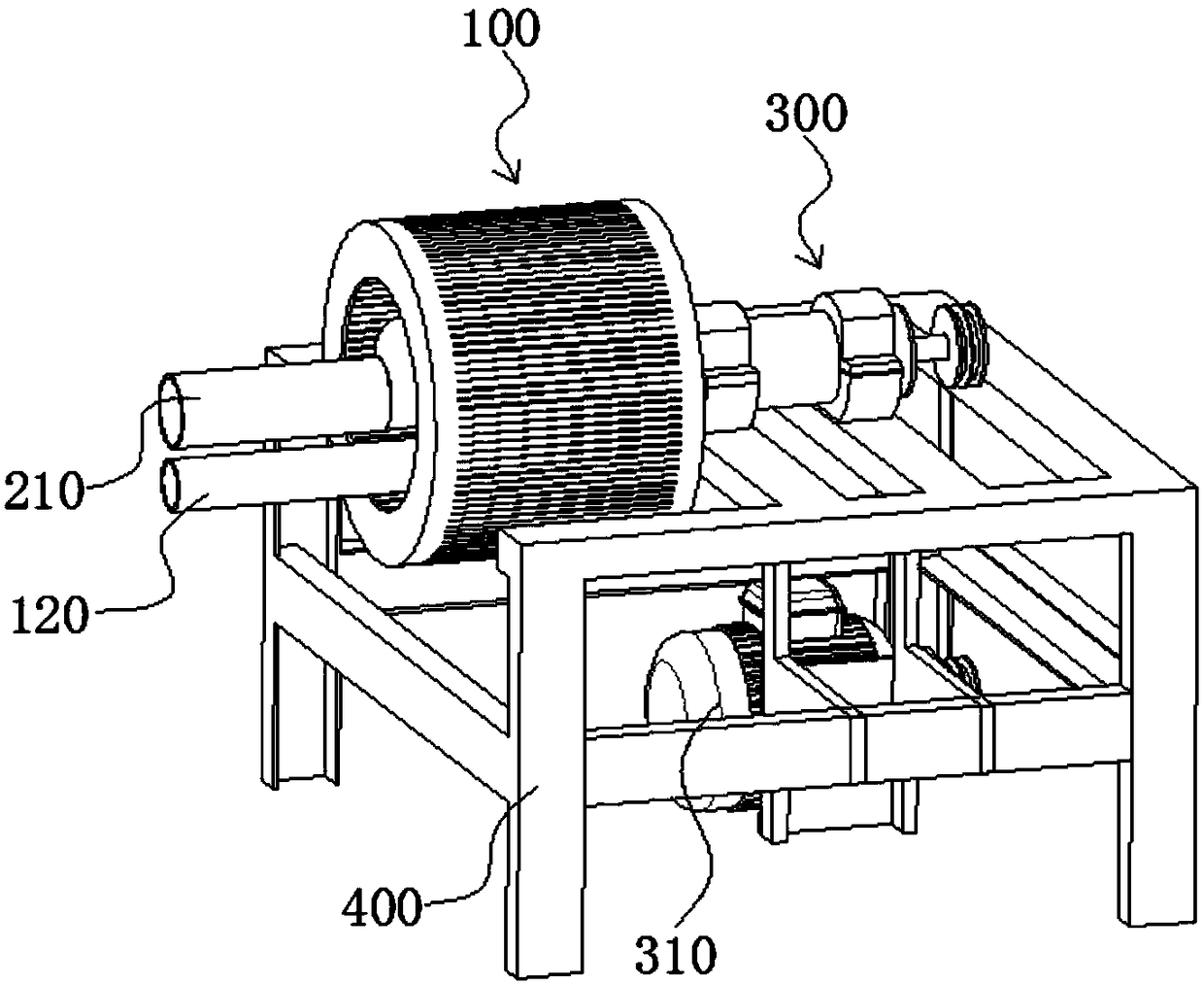

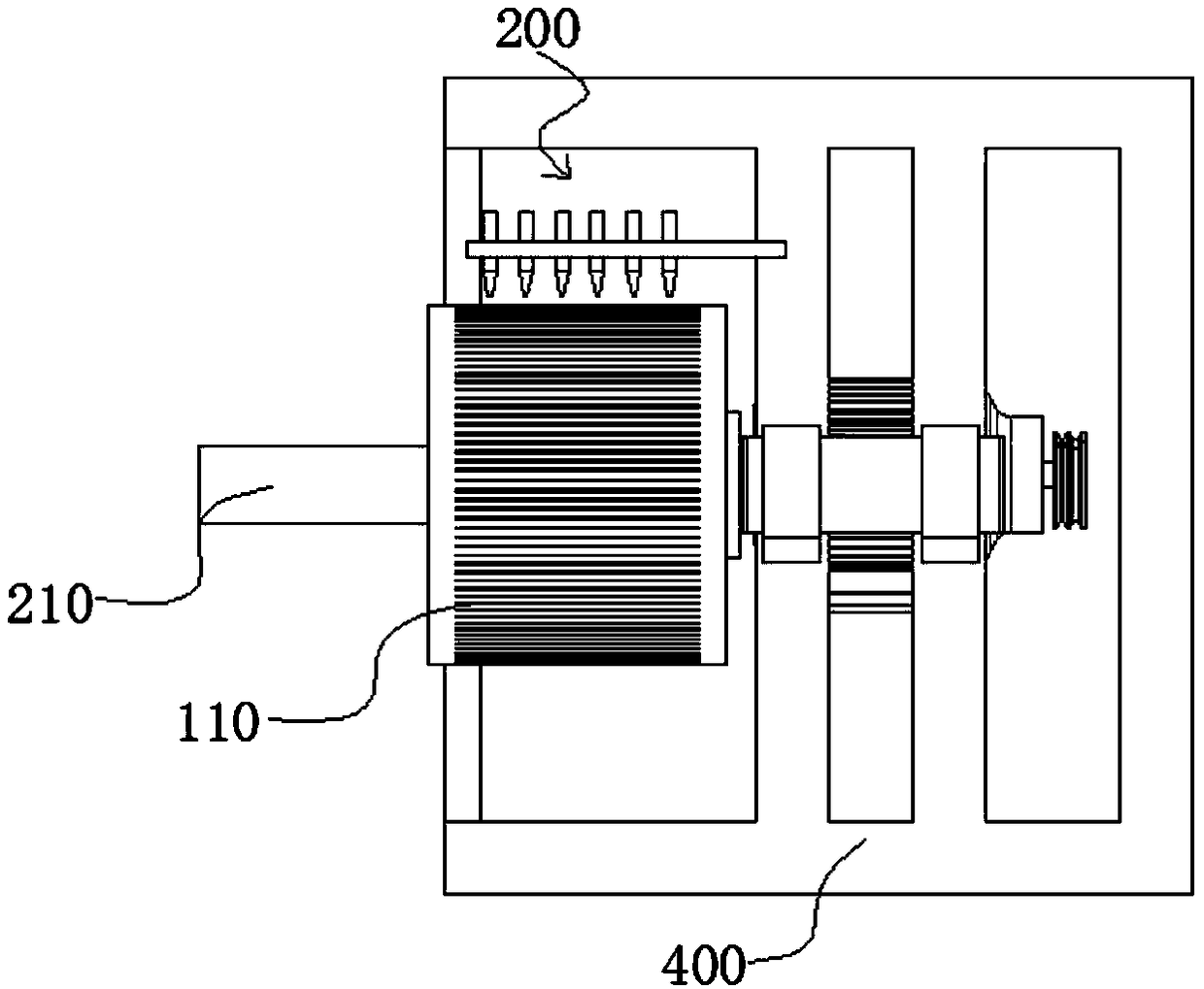

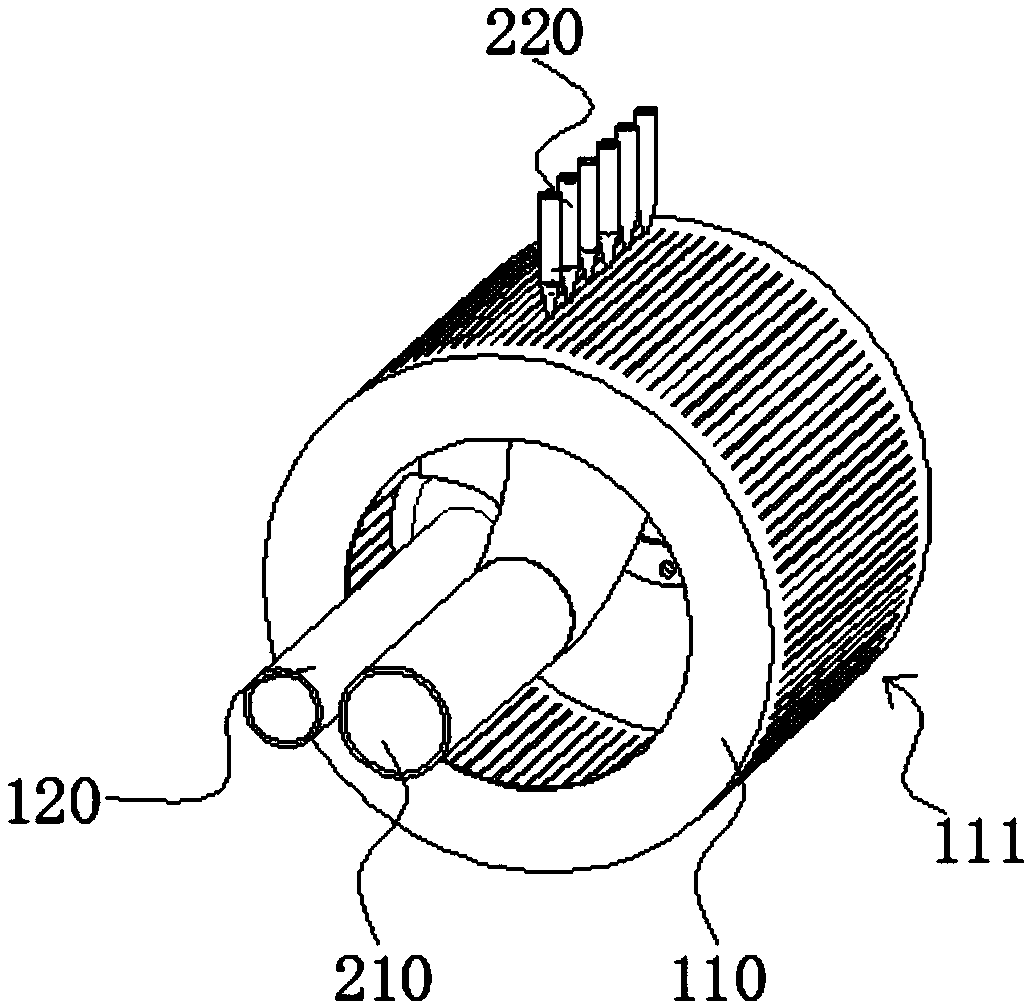

[0045] Such as Figure 1 to Figure 5 As shown, the first embodiment provides a centrifugal solid-liquid separator, including: a centrifuge body 100, a feed port for feeding solid-liquid mixture materials and a discharge device 200 for discharging solid materials; The machine body 100 includes a filter cylinder 110, the filter cylinder 110 is connected with a power assembly 300 for driving its rotation, and the filter cylinder 110 is provided with a water filtering structure 111 for filtering out the liquid material in the filter cylinder 110; The discharge device 200 includes a pneumatic assembly and a discharge pipe 210, and the air pressure assembly can provide high-speed air flow to blow the solid material in the filter cylinder 110 to the discharge pipe 210, and output through the discharge pipe 210; It communicates with the filter cylinder 110.

[0046] In the centrifugal solid-liquid separator, the solid-liquid mixture enters the filter screen cylinder 110 through the f...

Embodiment 2

[0067] Such as Figure 6 to Figure 9 As shown, the second embodiment also provides a centrifugal solid-liquid separator, the centrifugal solid-liquid separator includes parts and components with the same names and working principles as those in the first embodiment, and its structure is the same as that of the above-mentioned embodiment A centrifugal solid-liquid separator is basically the same, the differences are as follows.

[0068] In the second embodiment, the centrifuge body 100 also includes an outer cylinder 130, the outer cylinder 130 is arranged on the outside of the screen cylinder 110, and a water-holding annular cavity for accommodating liquid materials can be formed between the two; the water filtering structure 111 It communicates with the water-holding ring cavity, and the outer cylinder 130 is provided with a liquid outlet, and the liquid outlet communicates with the water-holding ring cavity.

[0069] Since the outer cylinder 130 is provided on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com