Automatic waste collection device of stamping die

A technology for automatically collecting and stamping dies, applied in the field of stamping dies, can solve the problems of carrying damaged products, time-consuming and laborious cleaning of scraps, cracking knife edges, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

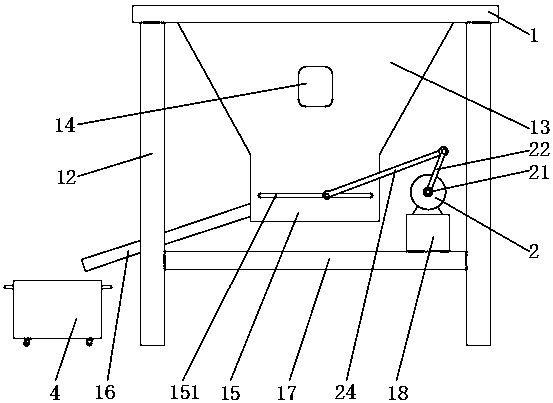

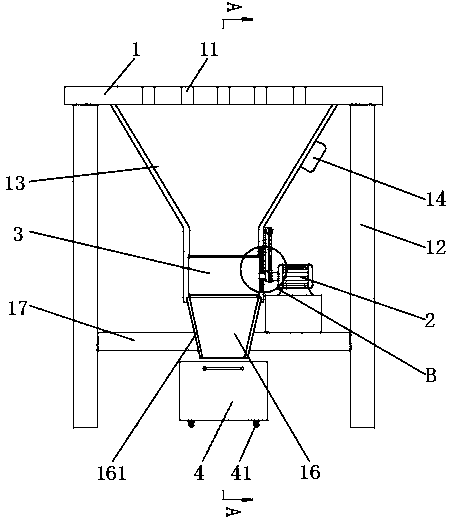

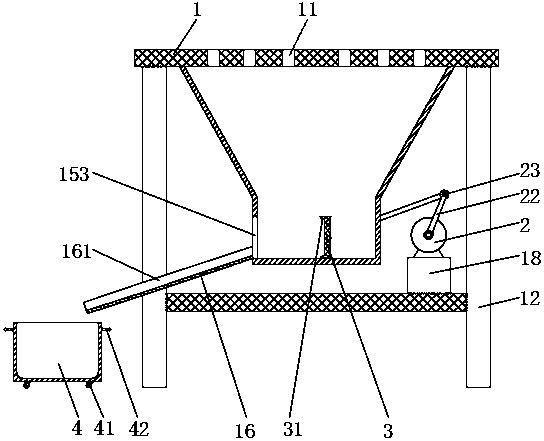

[0028] Example 1, see Figure 1-4 , the present invention provides a technical solution: a stamping die automatic waste collection device, including a stamping platform 1, a motor 2, a push plate 3 and a waste box 4, the top of the stamping platform 1 is 1.2 meters away from the ground, and the top of the stamping platform 1 is installed There is a stamping mold, and a mold punching hole 11 is provided inside the stamping platform 1. The mold punching hole 11 corresponds to the position where the lower mold of the mold installed on the top of the stamping platform 1 is impacted and pierced by the upper mold of the mold fixed on the top of the press. To accept the metal block punched out after piercing, the four ends of the bottom of the stamping platform 1 are fixed with support legs 12 by welding, and the inner sides of the four support legs 12 are horizontally fixed with a horizontal plate 17, which can support the four support legs 12 , other tools needed for stamping can a...

Embodiment 2

[0039] Example 2, see Figure 5 , in Embodiment 1, the top and bottom of both sides of the pusher plate 3 are provided with a block 31 inclined inwardly, and the two sides perpendicular to the material receiving box 15 and the slide hole 151 are provided with a discharge port 153, The motor 2 drives the second connecting rod 24 to push the push plate 3 to reciprocate left and right, and the waste materials can be pushed out from the discharge ports 153 on both sides of the material receiving box 15 respectively, and then enter the conveying plates 16 on both sides and be transported to both sides waste bin 4.

Embodiment 3

[0040] Embodiment 3. In Embodiment 1, a fixed head 21 is fixed at the output end of the motor 2, a transmission shaft is fixed on the other side of the fixed head 21, and first connecting rods 22 are respectively fixed on both sides of the transmission shaft. The connecting rod 22 will rotate along with the output end of the motor 2, and the end of the first connecting rod 22 is rotated to connect the second connecting rod 24 through the rotating shaft 23 respectively, and the two sides of the chute 152 are opened in the receiving box 15 respectively. Sliding hole 151 is opened, and cylinder 32 is respectively fixed in the middle of both sides of pushing plate 3 close to sliding hole 151, and both sides of cylinder 32 pass through sliding hole 151 and second connecting rod 24 are rotated and connected respectively. By turning on the motor 2, the motor 2 will drive the two first connecting rods 22 to rotate together, and the first connecting rod 22 will drive the second connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com