Feeding mechanism of intermediate-frequency inversion spot welder

A technology of spot welding machine and intermediate frequency, which is applied in the field of feeding mechanism of intermediate frequency inverter spot welding machine, which can solve the problems of too many welding parts and the inability of spot welding machine to complete high-quality welding work, and achieve high positioning and conveying accuracy, Effect of improving welding quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

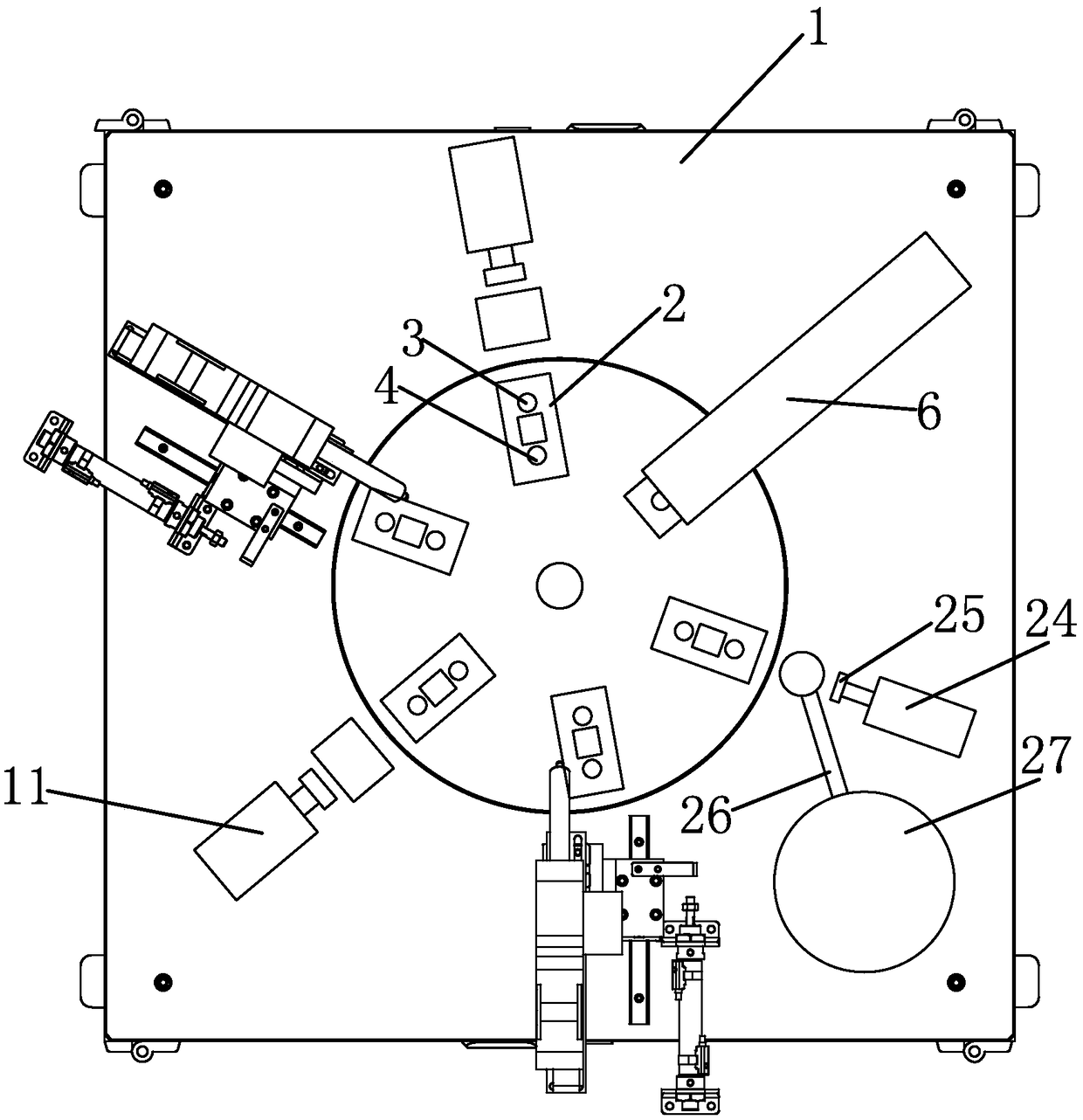

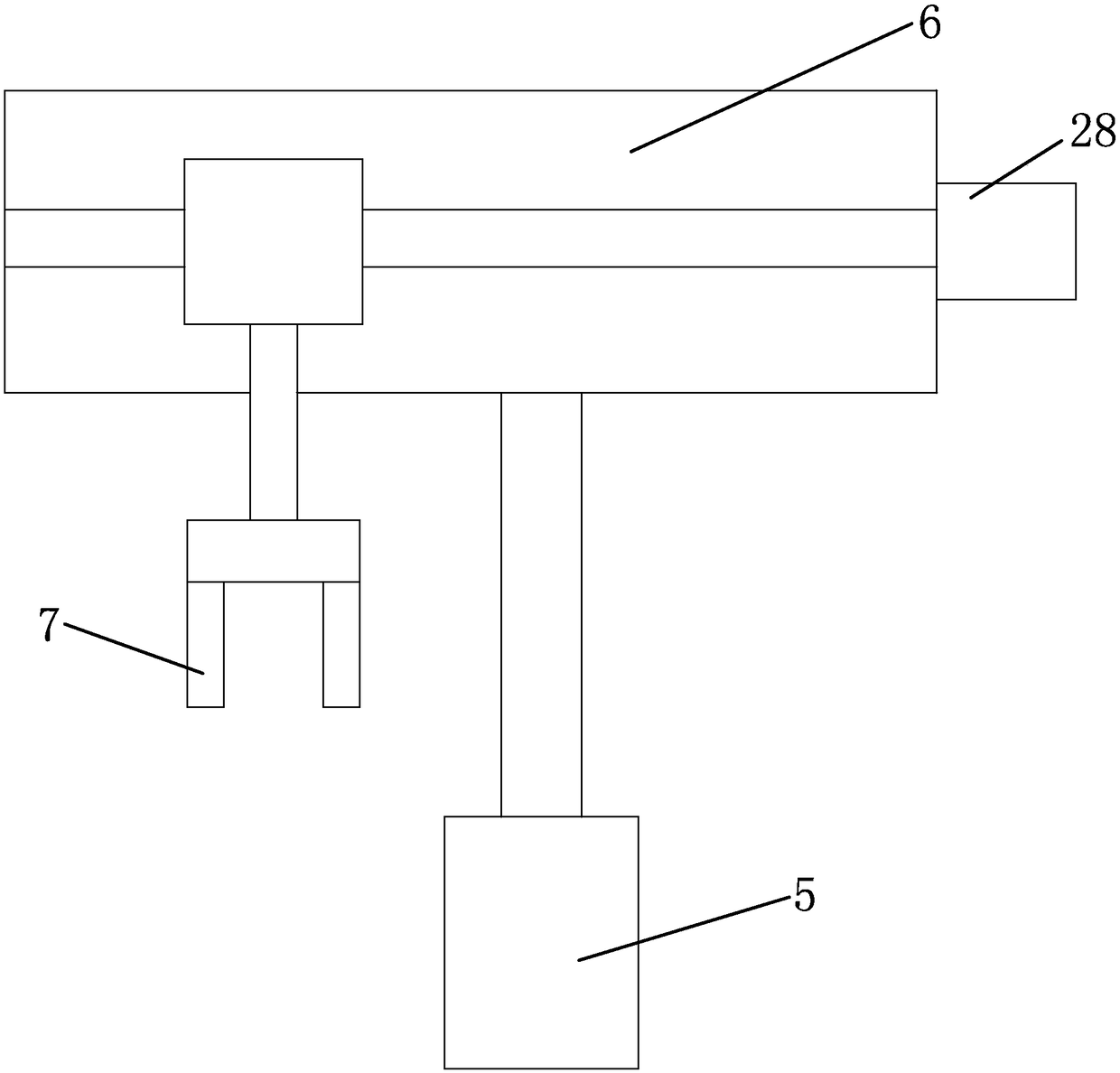

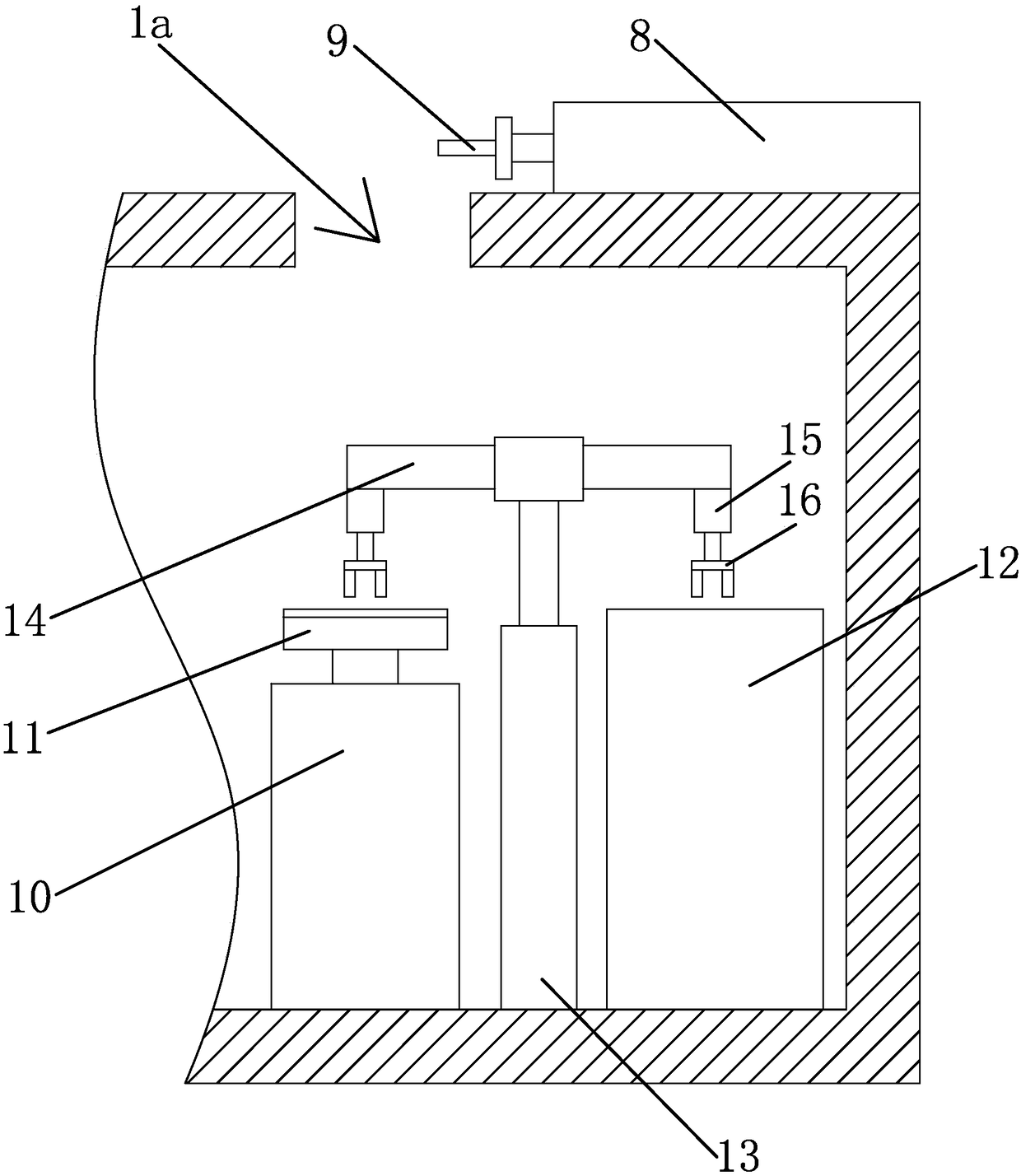

[0026] Such as Figure 1-4 As shown, an intermediate frequency inverter spot welding machine includes a working box 1, which has a cavity, and the top of the working box 1 is provided with a turntable, and the turntable is provided with six welding stations 2, six welding stations 2 Divided in a ring with equal intervals, the welding table 2 is equipped with the lower electrode 1 3 and the lower electrode 2 4, and the outer periphery of the turntable is sequentially provided with a feeding mechanism that can place the part 1 on the welding table 2, and can place the part 2 on the welding table. The feeding mechanism on 2, the welding mechanism 1 that can weld part 1 and part 2, the feeding structure that can place part 3 o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap