Conveying equipment

A technology for conveying equipment and conveyor belts, which is applied in the field of transmission and can solve problems such as insufficient conveyance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

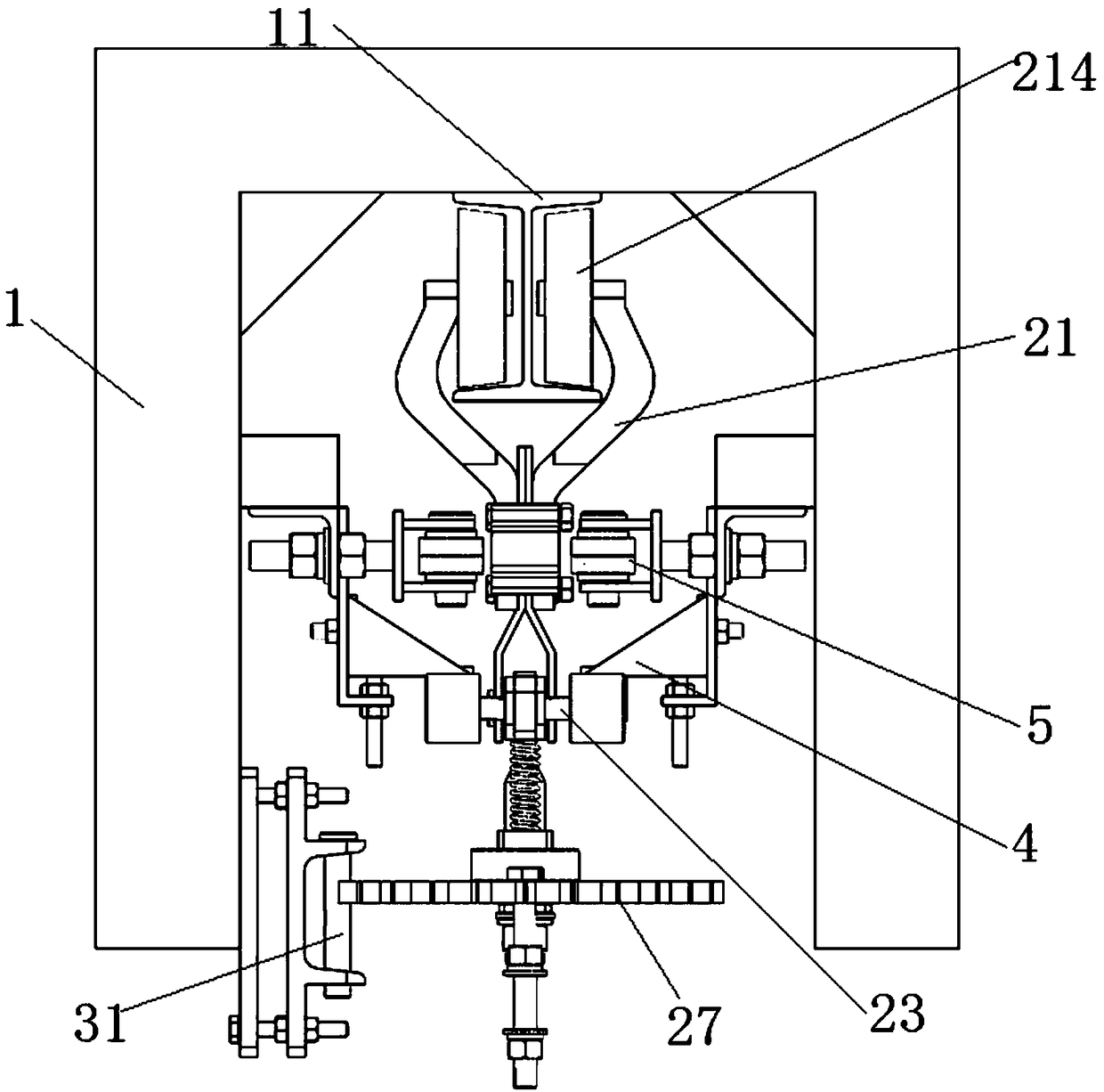

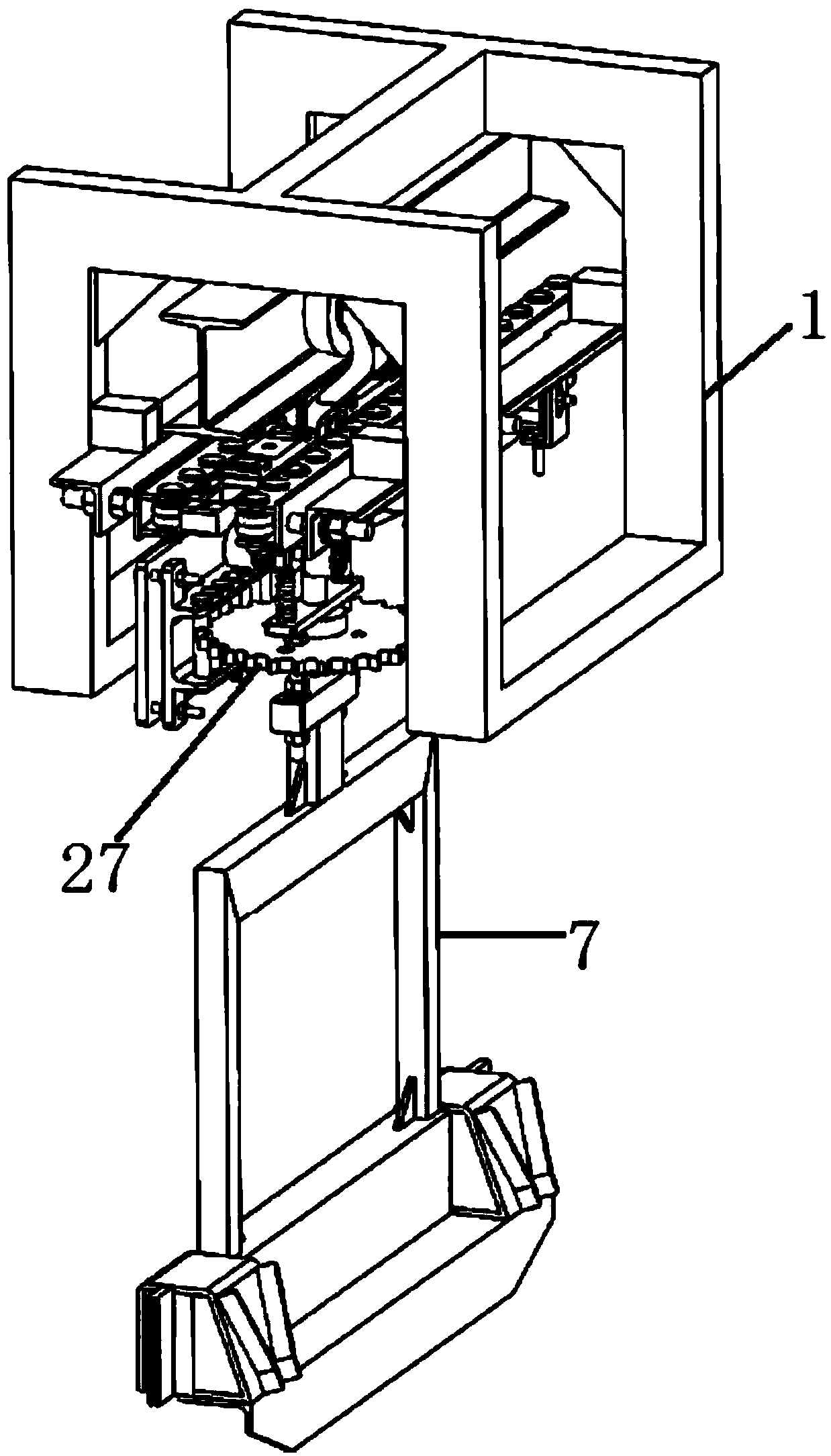

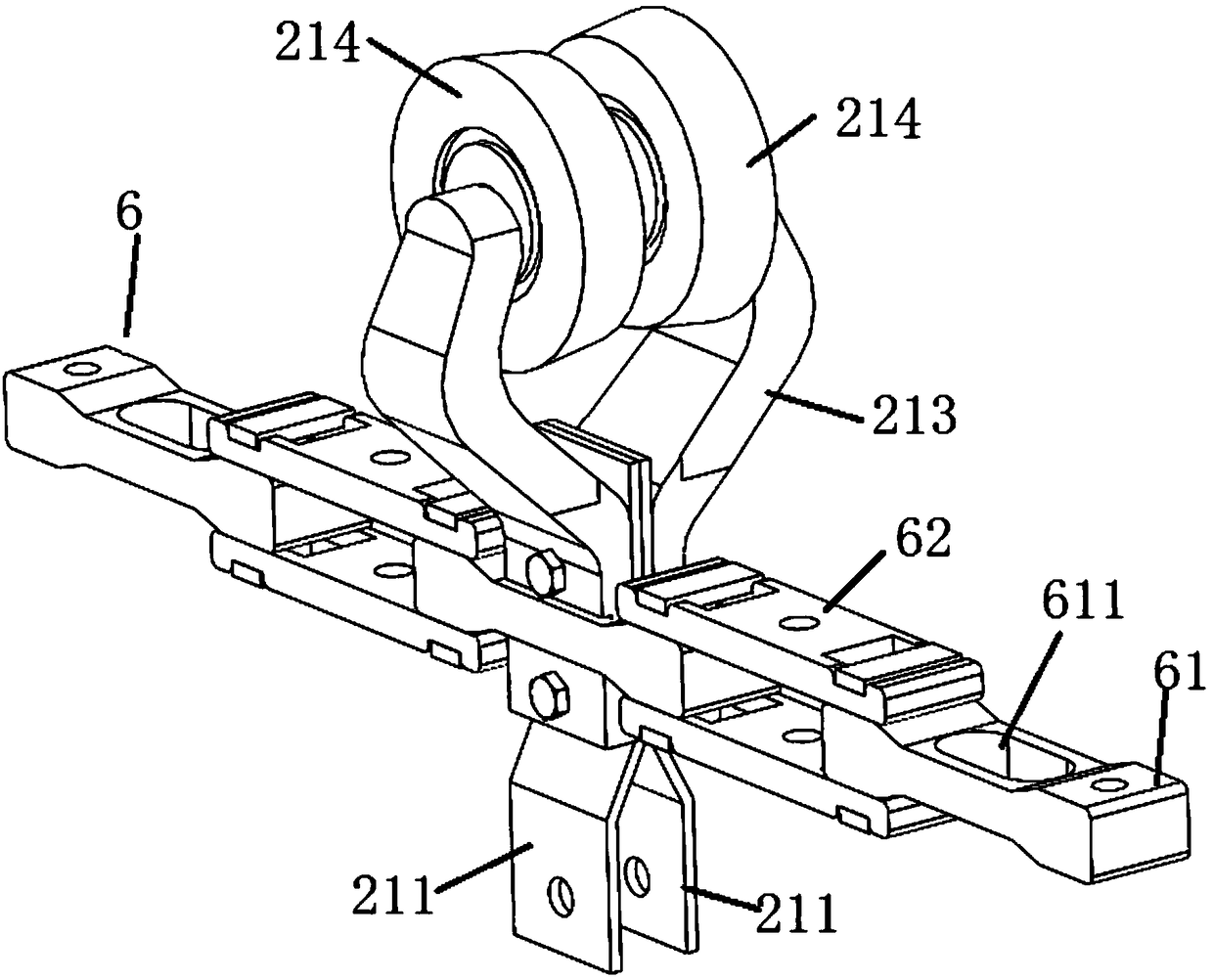

[0079] This embodiment provides a conveying device, which includes a base frame 1 , a transmission chain 6 and a plurality of suspension structures 2 . Wherein, the transmission chain 6 is a closed loop and is slidably arranged on the base frame 1 . For example, the transmission chain 6 is a chain, and the two ends of the pedestal 1 are respectively provided with a driving wheel and a driven wheel. The transmission chain 6 is wound around the outside of the driving wheel and the driven wheel. The driving wheel is driven to rotate, and the driven wheel is driven to rotate through the transmission chain 6 to realize the slidable arrangement of the transmission chain 6 on the base frame 1 .

[0080] A plurality of suspension structures 2 are vertically suspended on the transmission chain 6 , a required gap is reserved between two adjacent suspension structures 2 , and the transmission chain 6 drives the suspension structures 2 to slide linearly on the base frame 1 . like figure...

Embodiment 2

[0119] This embodiment provides a conveying device, which is different from the conveying device provided in Embodiment 1 in that:

[0120] The rack 31 is not provided on the base frame 1, and the rotating member 27 may or may not be a gear. For example, a turntable is used instead of a gear, or a rotating member 27 of any shape. For example, the rotating part 27 is a square, T-shaped, S-shaped rotating wheel or a rotating disk, and only the hanger 7 needs to be installed on the rotating part 27 to get final product. The hanger 7 can be directly fixed on the rotating member 27 , or can be suspended or detachably installed on the rotating member 27 . When the rack 31 is not provided on the base frame 1, a separate driver, such as a rotating motor, is required to drive the rotating member 27 to rotate. Other structures of the conveying equipment in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0122] This embodiment provides a conveying device, which is different from the conveying device provided in Embodiment 1 or Embodiment 2 in that:

[0123] The abutment surface 43 may not be a horizontal plane, the first slope surface 41 and the second slope surface 42 may be asymmetrical, and the abutment surface 43 may be an uneven surface. Since the abutment surface 43 is located below the first slope surface 41, as long as the When the roller 235 in the positioning mechanism abuts against the abutting surface 43, the bottom of the limiting member 22 can be kept completely away from the rotating member 27, and the limiting effect on the rotating member 27 can be released. Whether the abutting surface 43 is a horizontal plane is not limited.

[0124] As a second alternative implementation of Example 2, in the horizontal direction, the sum of the length of the abutting surface 43 and the length of the second slope 42 is greater than the arc length of the angle required for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com