Six-axis robot

A six-axis robot, the sixth technology, applied in the field of robotics, can solve the problems of high production process and stability requirements, insufficient connection relationship, high production cost, etc., and achieve the effects of reduced production cost, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

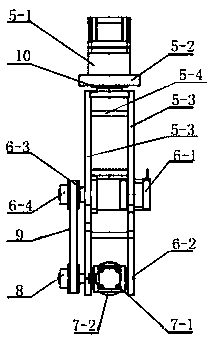

[0019] Such as Figure 1 to Figure 6 As shown, the present invention discloses a six-axis robot, including a general control center, a base 1, a first-axis mechanical arm 2 sequentially installed on the base 1, and a second-axis mechanical arm 3 connected to the first-axis mechanical arm 2 , the third-axis robotic arm 4 connected to the second-axis robotic arm 3, the fourth-axis robotic arm 5 connected to the third-axis robotic arm 4, the fifth-axis robotic arm 6 connected to the fourth-axis robotic arm 5, and The fifth-axis mechanical arm 6 is connected to the sixth-axis mechanical arm 7. The fourth-axis mechanical arm 5 includes a motor A5-1, a connecting plate A5-2 arranged on the motor A5-1, and on the right side of the connecting plate A5-2. A pair of parallel arms A5-3 is arranged on the side, and a connecting column 5-4 is arranged between the pair of parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com