Polyurethane modified polylol and polyurethane foam plastic prepared from polyurethane modified polylol

A polyurethane modification and polyurethane foam technology, which is applied in the field of polyurethane foam plastics, can solve the problems of high semi-rigid foam, reduced mechanical strength, and low mechanical strength, and achieve high porosity, small shrinkage, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

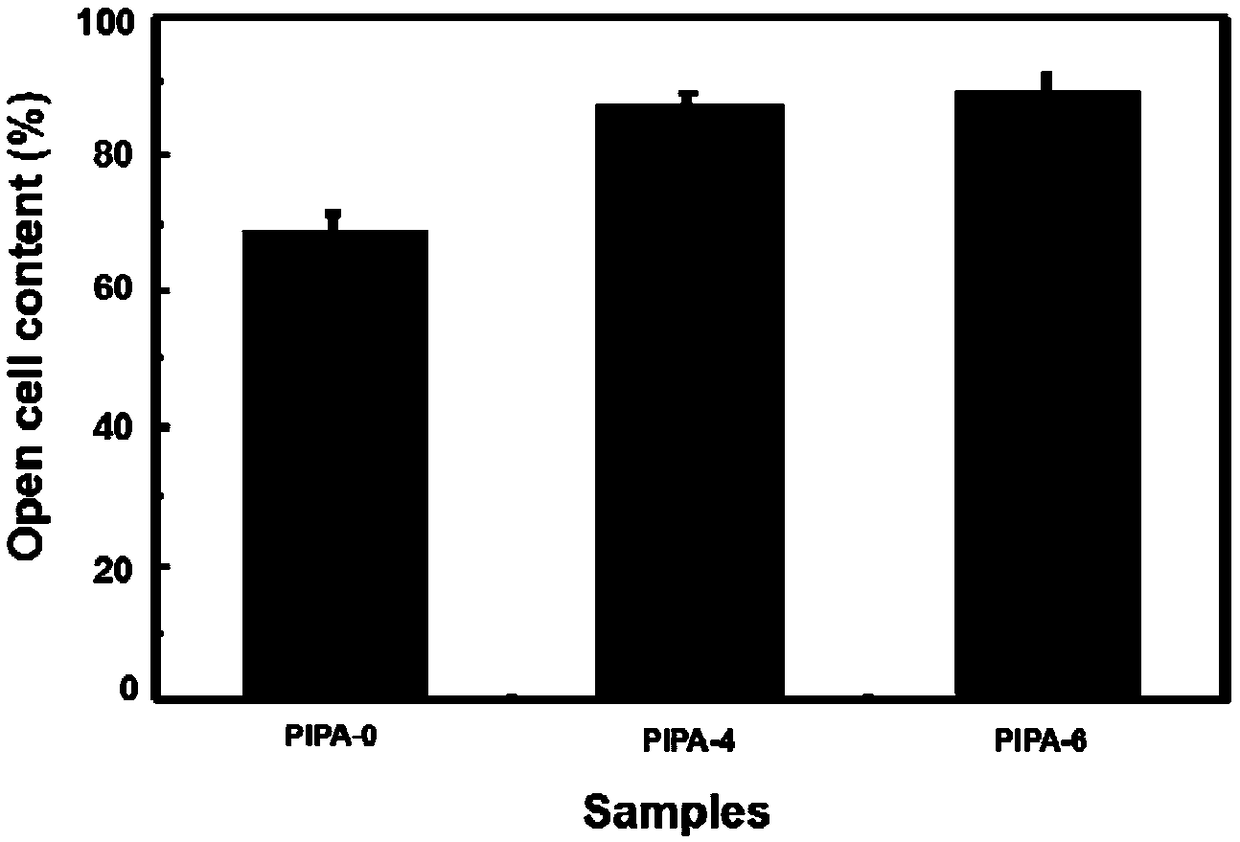

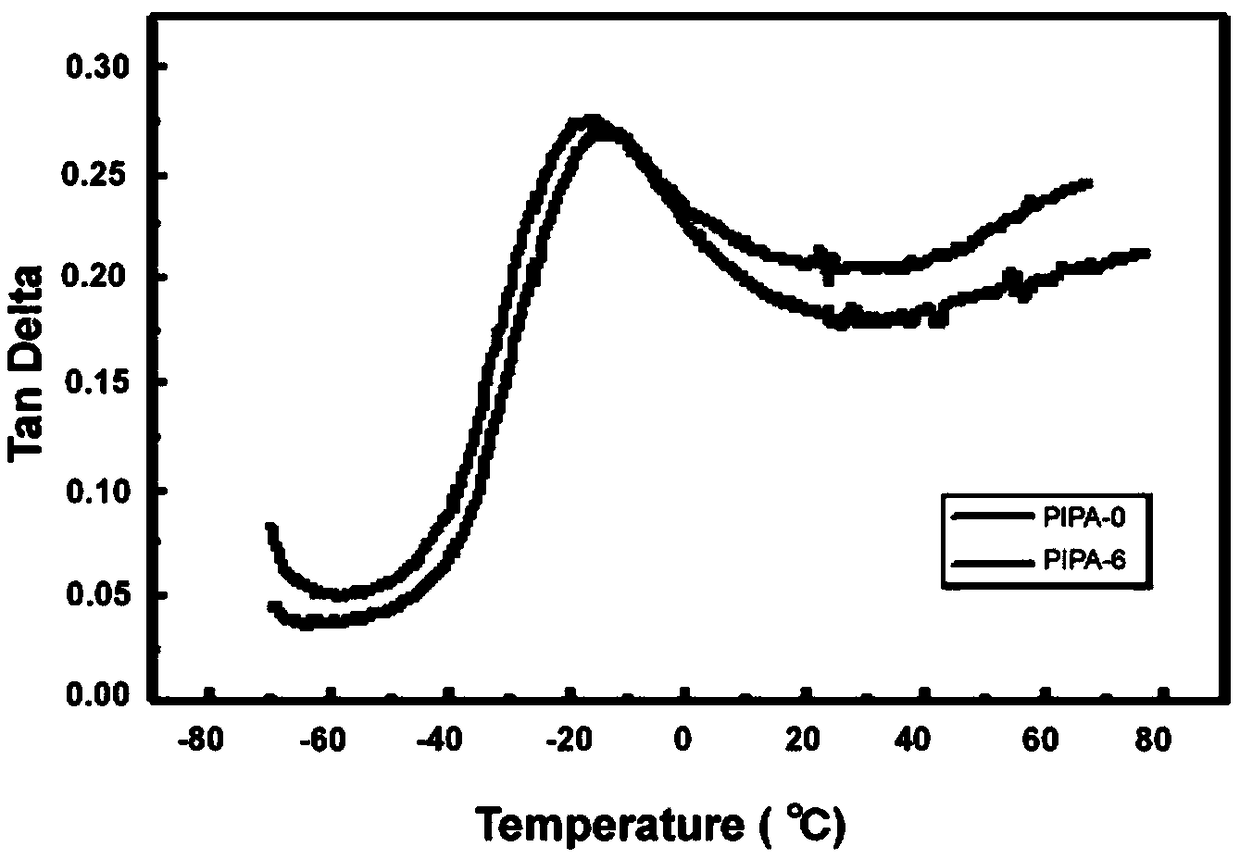

[0030] Embodiment 1 The preparation of polyurethane modified polyol and polyurethane foam of the present invention

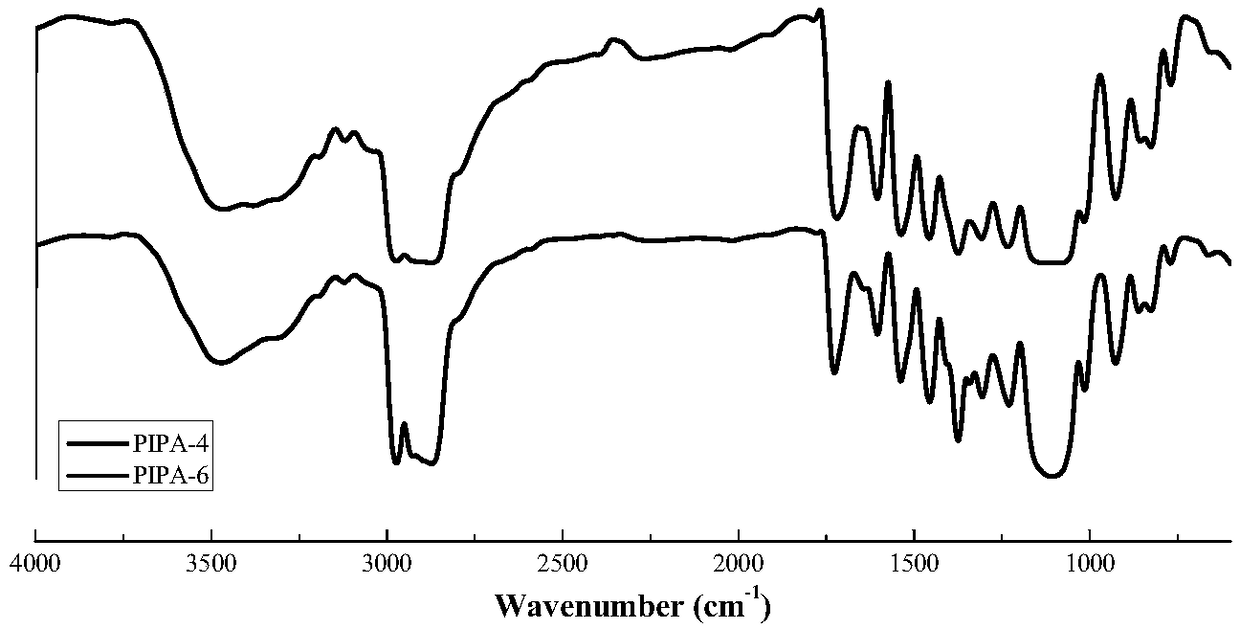

[0031] 1. Preparation of polyurethane modified polyol PIPA-4

[0032] Take 100g of polyether polyol (3050A), 4g of 1,4-butanediol and 0.2g of dibutyltin dilaurate, control the speed of electric stirrer not higher than 500rpm, stir and mix for 2min, then add diphenylmethane diisocyanate (MDI) 5.0-15.0g, control the rotational speed not higher than 500rpm, stir and mix for 5 minutes, vacuumize to remove air bubbles, and obtain polyurethane modified polyol (PIPA-4).

[0033] 2. Preparation of polyurethane foam A-1

[0034] Take polyether polyol (3050A) 160g, PIPA-4 40g, 1,4-butanediol 4~8g, foaming agent (water) 2.8g, dibutyltin dilaurate 0.1~0.8g, 33% triethylenediol 1.0-3.0g of amine solution (dipropylene glycol as the solvent), 3g of foam stabilizer (L580), stir and mix with an electric mixer at high speed for 60s at a speed of 3000rpm, then add MDI 110-135g, ...

Embodiment 2

[0035] Embodiment 2 The preparation of polyurethane modified polyol and polyurethane foam of the present invention

[0036] 1 Preparation of Polyurethane Modified Polyol PIPA-6

[0037] Take 100g of polyether polyol (3050A), 6g of 1,4-butanediol and 0.2g of dibutyltin dilaurate, control the speed of electric stirrer not higher than 500rpm, stir and mix for 2min, then add diphenylmethane diisocyanate (MDI) 5.0-15.0g, control the rotational speed not higher than 500rpm, stir and mix for 5 minutes, vacuumize to remove air bubbles, and obtain polyurethane modified polyol (PIPA-6).

[0038] 2. Preparation of polyurethane foam A-2

[0039] Take 160g of polyether polyol (3050A), 40g of PIPA-6, 4-8g of 1,4-butanediol, 2.8g of foaming agent (water), 0.1-0.8g of dibutyltin dilaurate, 33% triethylenediol 1.0-3.0g of amine solution (dipropylene glycol as the solvent), 3g of foam stabilizer (L580), stir and mix with an electric mixer at high speed for 60s at a speed of 3000rpm, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com