Catalyst for addition type silicone rubber cured at low temperature and preparation method thereof

A catalyst and silicone rubber technology, applied in the low temperature curing catalyst for addition type silicone rubber and its preparation field, can solve problems such as easy leakage, and achieve the effects of avoiding reaction, convenient use and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

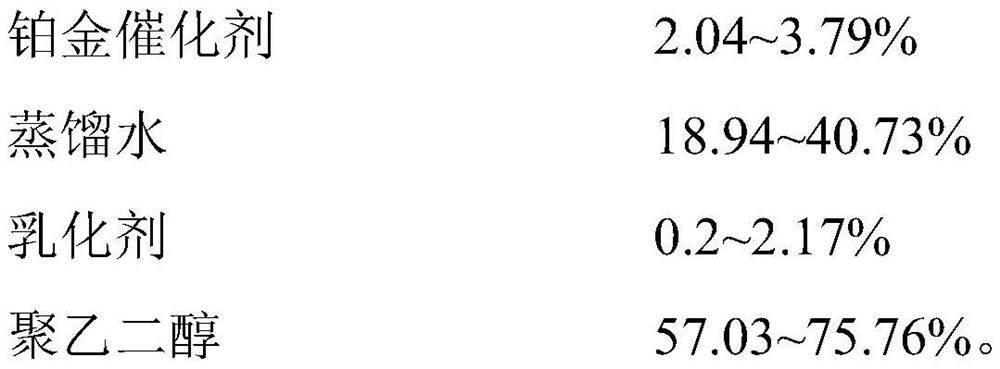

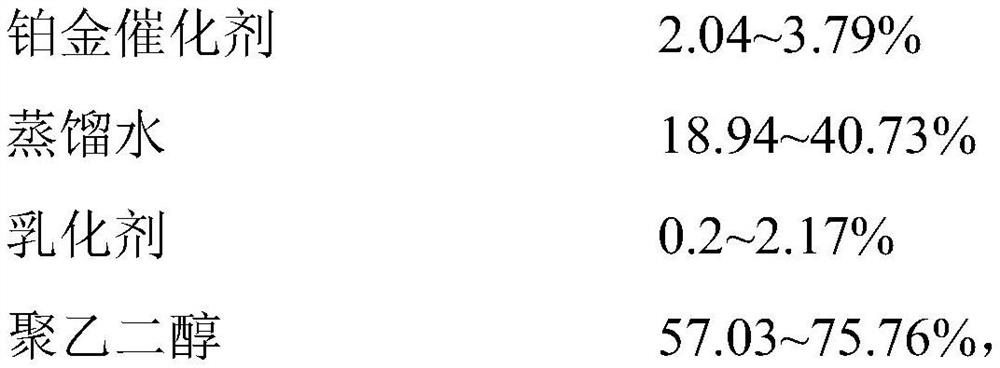

Embodiment 1

[0027] Platinum catalyst emulsification: 10 grams of Custer platinum catalyst of 1000 ppm, 100 grams of distilled water and 6 grams of gum arabic are placed in a three-necked flask with a stirrer, and stirred for 1.5 hours at a speed of 1500 rpm to obtain oil- water emulsion;

[0028] Composite with polyethylene glycol: put the oil-water emulsion in a water bath and heat up to 65°C, keep the stirring speed at 1500 rpm, gradually add 160 grams of polyethylene glycol with an average molecular weight of 18000 to the oil-water emulsion alcohol;

[0029] Distillation under reduced pressure: raise the reaction temperature to 97°C, vacuumize and reduce pressure, and distill and stir for 1 hour until the reactant appears milky white;

[0030] Cooling and stirring: Stop heating and vacuum decompression, reduce the stirring speed to 300 rpm, and continue stirring for 3 hours. When the reaction temperature drops below 40°C, add ice cubes to the water bath until the reaction temperature ...

Embodiment 2

[0036] Platinum catalyst emulsification: 8 grams of Custer platinum catalysts with a concentration of 1500ppm, 100 grams of distilled water and 4 grams of gum arabic are placed in a three-necked flask with a stirrer, and stirred for 1 hour at a speed of 2000 rpm to obtain oil- water emulsion;

[0037] Composite with polyethylene glycol: put the oil-water emulsion in a water bath and heat up to 70°C, keep the stirring speed at 2000 rpm, gradually add 200 grams of polyethylene glycol with an average molecular weight of 15000 to the oil-water emulsion alcohol;

[0038] Distillation under reduced pressure: raise the reaction temperature to 95°C, vacuumize and reduce pressure, and distill and stir for 1.5 hours until the reactant appears milky white;

[0039] Cool down and stir: Stop heating and vacuum decompression, reduce the stirring speed to 500 rpm, and continue stirring for 2 hours. When the reaction temperature drops below 40°C, add ice cubes to the water bath until the rea...

Embodiment 3

[0045] Platinum catalyst emulsification: 3 grams of Custer platinum catalyst with a concentration of 5000ppm, 100 grams of distilled water and 2 grams of gum arabic were placed in a three-necked flask with a stirrer, and stirred for 0.5 hour at a speed of 3500 rpm to obtain oil- water emulsion;

[0046] Composite with polyethylene glycol: put the oil-water emulsion in a water bath and heat up to 75°C, keep the stirring speed at 3500 rpm, gradually add 300 grams of polyethylene glycol with an average molecular weight of 5000 to the oil-water emulsion alcohol;

[0047] Distillation under reduced pressure: raise the reaction temperature to 90°C, vacuumize and reduce pressure, and distill and stir for 2.5 hours until the reactant appears milky white;

[0048] Cool down and stir: Stop heating and vacuum decompression, reduce the stirring speed to 800 rpm, and continue stirring for 1.5 hours. When the reaction temperature drops below 40°C, add ice cubes to the water bath until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com