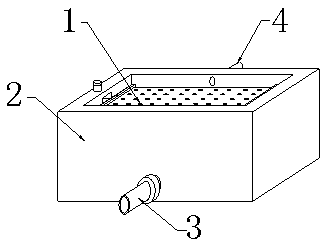

Silk soaking device

A technology of silk and soaking box, which is applied in the equipment configuration of processing textile materials, liquid/gas/vapor yarn/filament processing, processing textile material carriers, etc. problem, to achieve the effect of strong practicability, reasonable structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

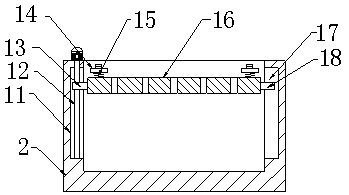

[0020] Specific implementation method: when in use, the operator first transports the soaking liquid into the soaking tank 2 through the liquid inlet pipe 4, and then the operator pulls the handle at the same time, and the handle simultaneously drives two sets of pressure plates 14 to move upward, and the two sets of pressure plates 14 simultaneously pull Stretch two groups of springs 15, the two groups of springs 15 are elastically deformed, then another operator places the left end and the right end of the silk respectively on the upper end surface of the carrier plate 16 directly below the two groups of pressure plates 14, and then releases the handle, the springs 15 Under the action of resilience, the pressing plate 14 is closely attached to the silk, and the pressing plate 14 fixes the silk on the carrier plate 16, and then the operator connects the driving motor circuit through the control switch, and the driving motor drives the screw rod 12 in the groove 11. Turn, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com