Variable cross-section high pier turnover formwork structure and construction method

A variable cross-section, high pier technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult control of construction, affecting the force of high pier and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

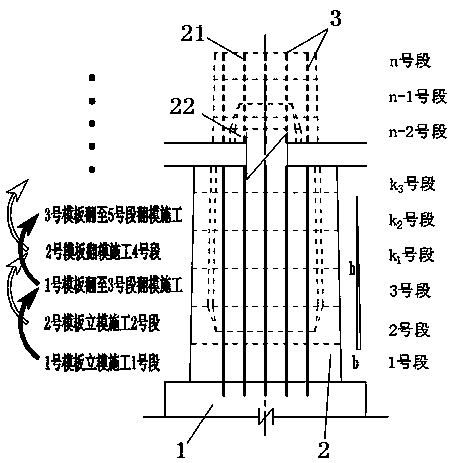

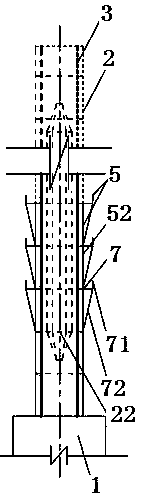

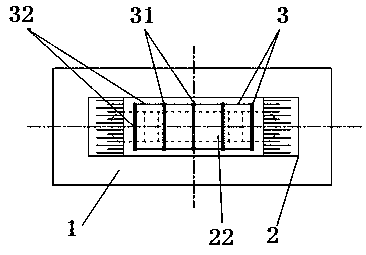

[0105] Such as Figure 1~Figure 6 As shown, 1. Foundation cap, 2. Pier body, 21. Concrete, 22. Empty stomach, 3. Rigid skeleton, 31. Sectional steel, 32. Ties, 4. Pier body reinforcement, 5. External formwork system, 51 .Outer horizontal formwork, 52. Outer longitudinal formwork, 53. Back corrugated, 54. Longitudinal tie rod, 55. Transverse tie rod, 56. Adjusting bolt, 57. Bolt, 6. Inner formwork system, 7. Steel working platform, 71. Railing, 72. diagonal brace.

[0106] The overturned formwork structure and construction method of variable cross-section high bridge piers, such as Figure 1~Figure 3 As shown, it involves the construction field of high concrete piers in bridges, and its structure is mainly composed of a foundation cap 1, a multi-section inner formwork system 6, a multi-section outer formwork system 5 and a stiff skeleton 3.

[0107] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com