Floor opening protective structure and installation method thereof

A technology for protective structures and floors, applied in building construction, construction, and building materials processing, etc., can solve the problems of less use, high manufacturing costs, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

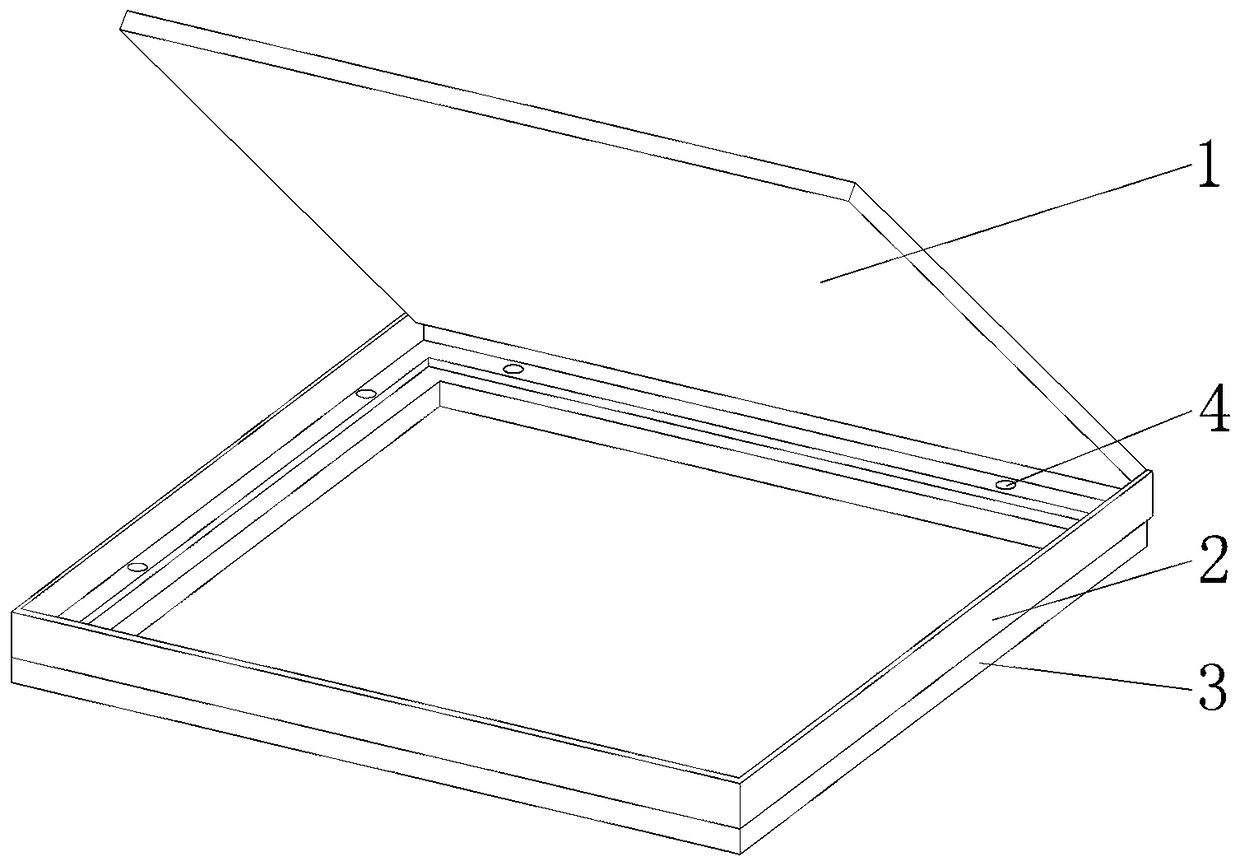

[0017] Such as figure 1 As shown, in this embodiment, the present invention is installed at the opening of the floor. It includes a cover plate 1, a protective frame 2 and a soft waterproof rubber strip 3 arranged from top to bottom. The cover plate 1 and the protective The frame 2 is matched, the protective frame 2 is fixedly matched with the soft waterproof rubber strip 3, and the protective frame 2 is provided with a reserved hole 4. The cover plate 1 is hingedly matched with the protective frame 2. The soft waterproof rubber strip 3 fits closely with the floor at the floor opening. The cover plate 1 is provided with a handle.

[0018] The method for installing a protective structure for a floor opening includes the following steps:

[0019] a. During the concrete pouring process, a nut tube is buried in advance on the edge of the hole at a position corresponding to the reserved hole 4, the nut tube is adapted to the reserved hole 4, and the nut tube is arranged With filler;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com