Spliced foldable protective device applied to building construction

A technology for building construction and protective devices, applied in the field of spliced foldable protective devices, can solve the problems of the guardrail mesh exceeding the edge of the working area, the difficulty of placing the guardrail stably, and the non-folding of the guardrail, so as to improve the protection efficiency and improve the protection. Effects, quick-release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

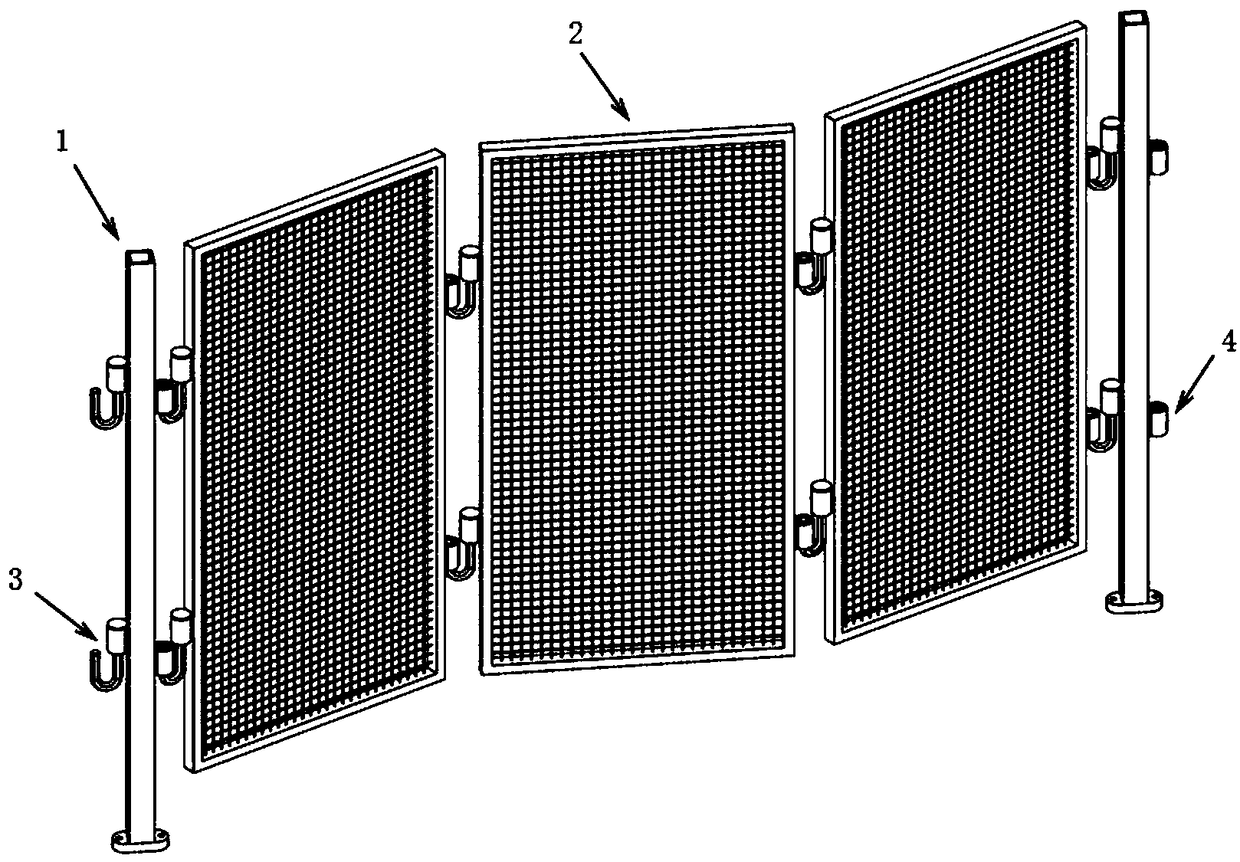

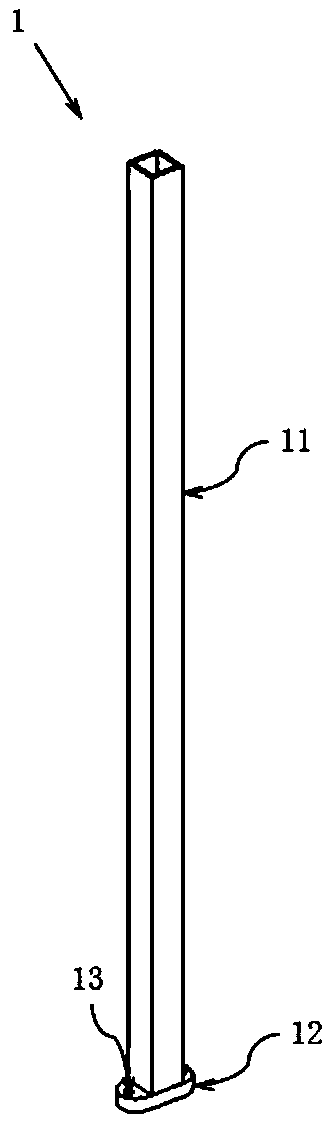

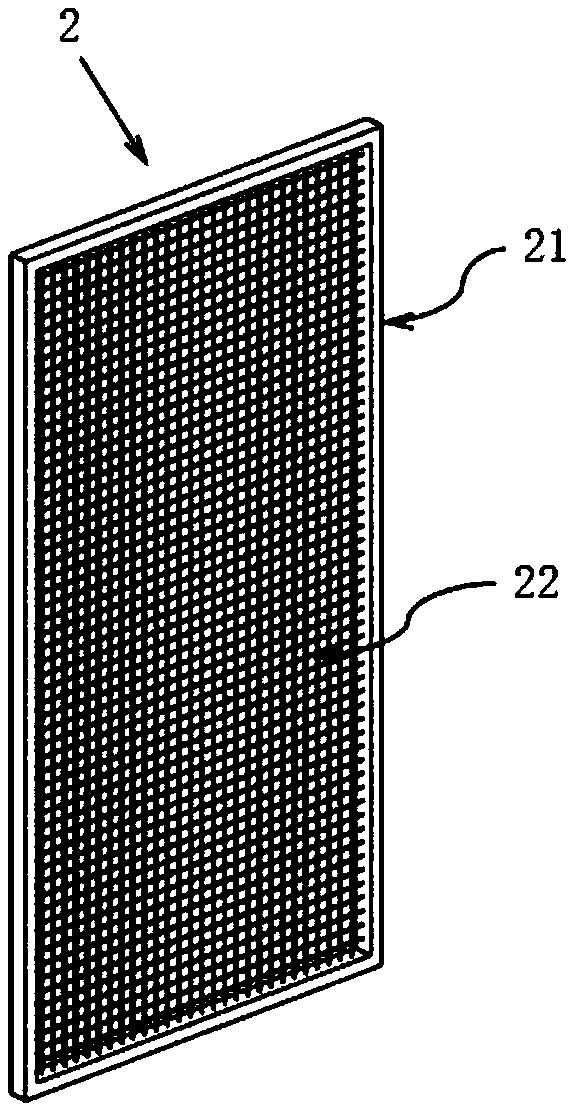

[0029] Shown in conjunction with the accompanying drawings is the first specific implementation of a spliced foldable protective device applied to building construction according to the present invention. First, in combination with figure 1 As shown, the protective device includes two columns 1 distributed at intervals, and three pieces of guardrail mesh 2 arranged between the two columns 1, specifically as figure 2 , image 3 As shown, the column 1 includes a pole 11 and a base 12 arranged at the bottom of the pole 11. The base 12 is provided with a through hole 13 that penetrates up and down and connects with the construction area through the through hole 13. The pre-embedded bolts are connected to fix the column 1, and the through holes 13 have two and are symmetrically distributed on both sides of the column 11; the guardrail mesh 2 includes a support frame 21 and a barbed wire 22.

[0030] The protection device also includes a connection mechanism connecting the colu...

Embodiment 2

[0040] Embodiment 2: The main difference between this embodiment and Embodiment 1 is that: the left and right sides of the middle piece of guardrail mesh 2 are respectively provided with two connecting female heads 4, and the left and right sides of the adjacent guardrail mesh 2 The sides are respectively provided with two connecting male heads 3 .

Embodiment 3

[0041] Embodiment 3: The main difference between this embodiment and Embodiment 2 is that: the two outermost columns 1 are respectively provided with four connection sockets 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com