Pressure-keeping coring method for marine drilling

A coring and marine technology, which is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems of coring failure, affecting the coring efficiency, and high construction risk, so as to expand the ability of coring and improve the success of coring rate, avoid the effect of deformation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

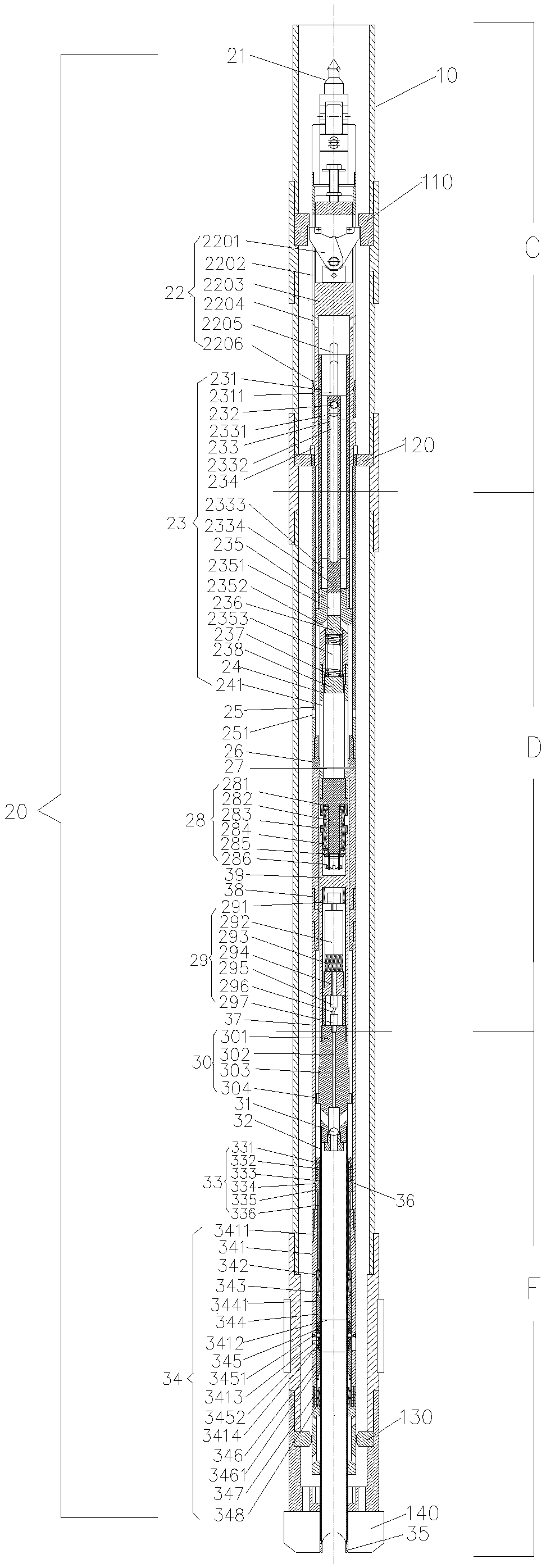

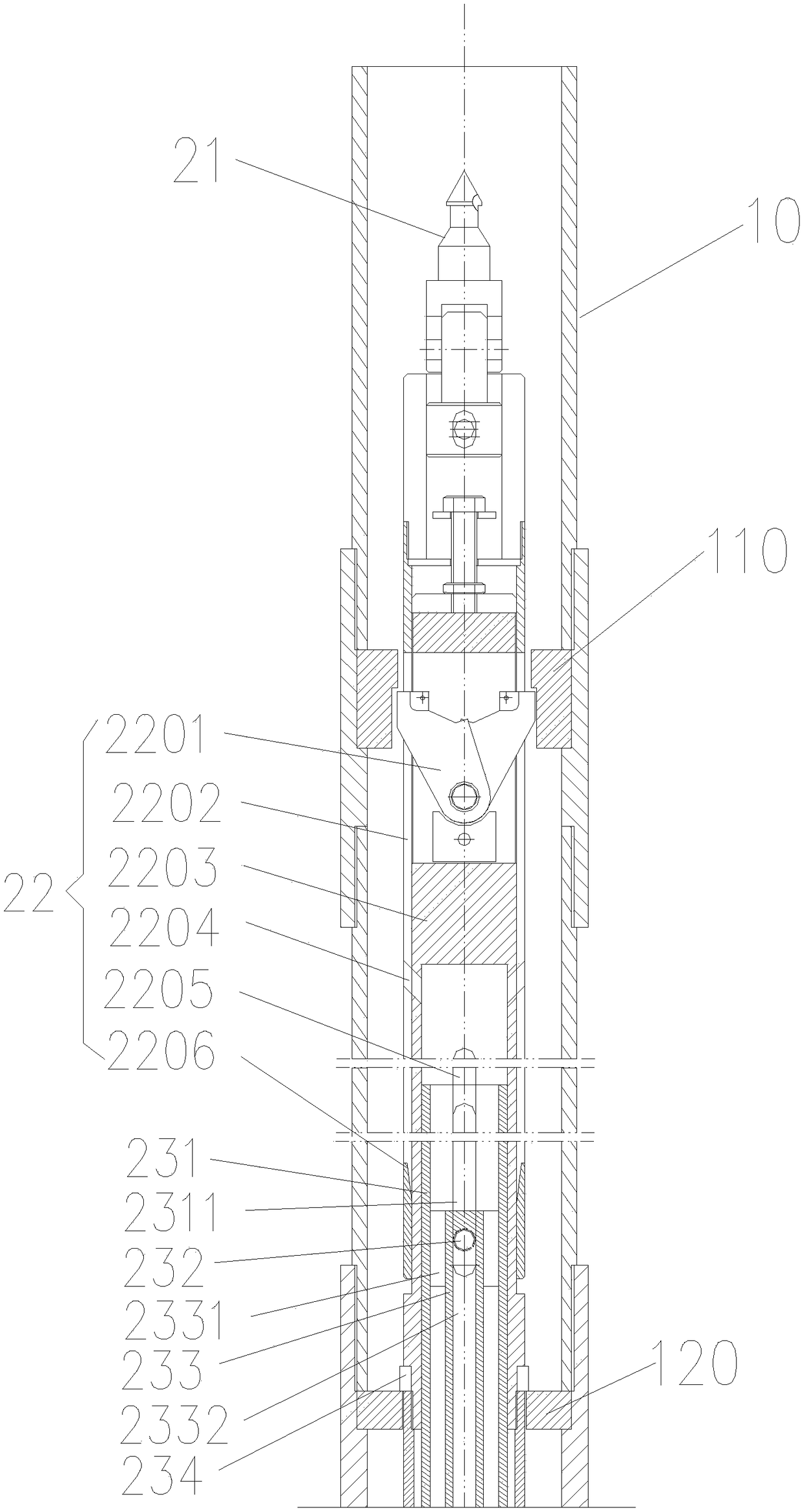

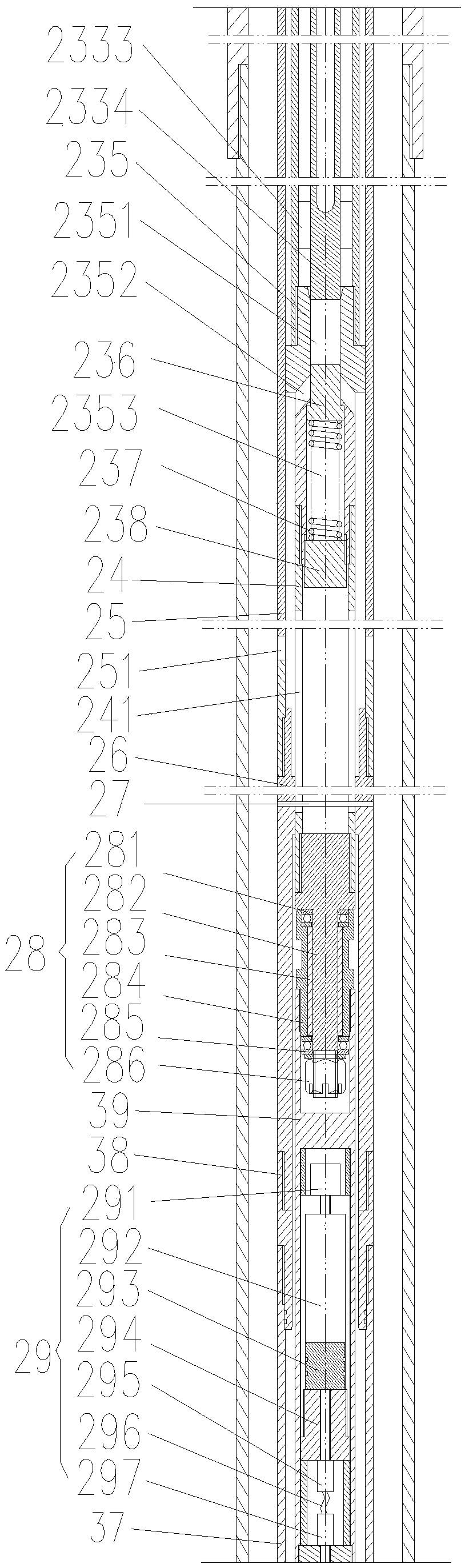

[0041] like Figures 1 to 17 Shown, a kind of marine drilling pressure-holding coring method is characterized in that: comprises the following steps:

[0042] 1) Putting the outer pipe assembly 10 to the bottom of the hole in advance, and putting the inner pipe assembly 20 into the outer pipe assembly 10 at the bottom of the hole through the salvage spearhead 21, and after putting it in place, carry out rotary coring at the bottom of the ocean;

[0043] 2) Keep the drilling fluid circulation, the drilling fluid makes the piston compensation and balance mechanism 23 push the core tube 32 to extend forward, the penetrating cutter head 35 is pressed down and does not rotate, the penetrating cutter head 35 stretches forward to press the bottom of the hole, and the penetrating cutter head 35 After penetrating into the formation, start to rotate the outer pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com