Efficient energy-saving gas boiler

A gas-fired boiler, high-efficiency and energy-saving technology, applied in the direction of wind power generation, engine function, wind engine consistent with the wind direction, etc., can solve the problems of energy waste and low power generation efficiency, and achieve the effect of solving energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

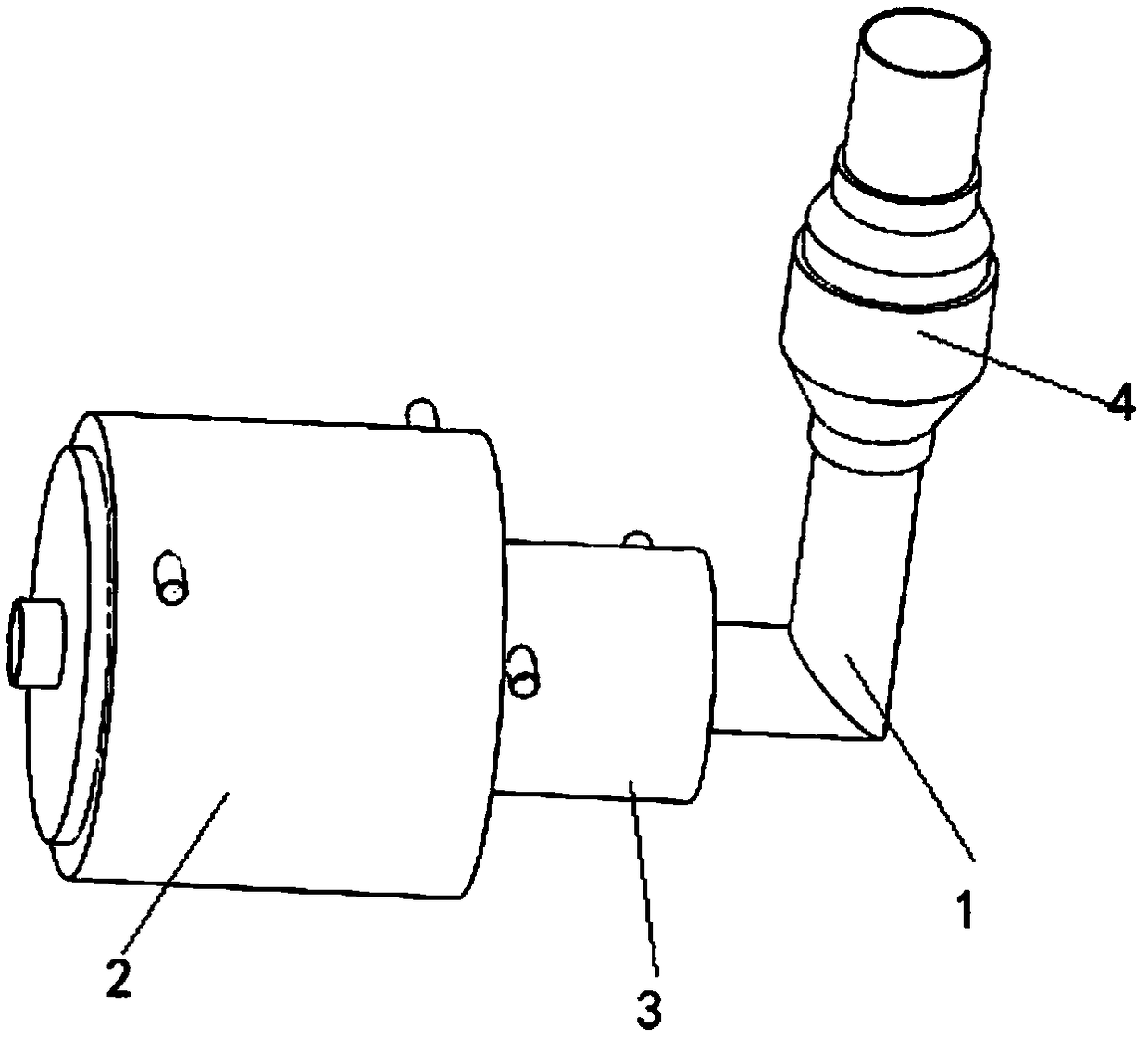

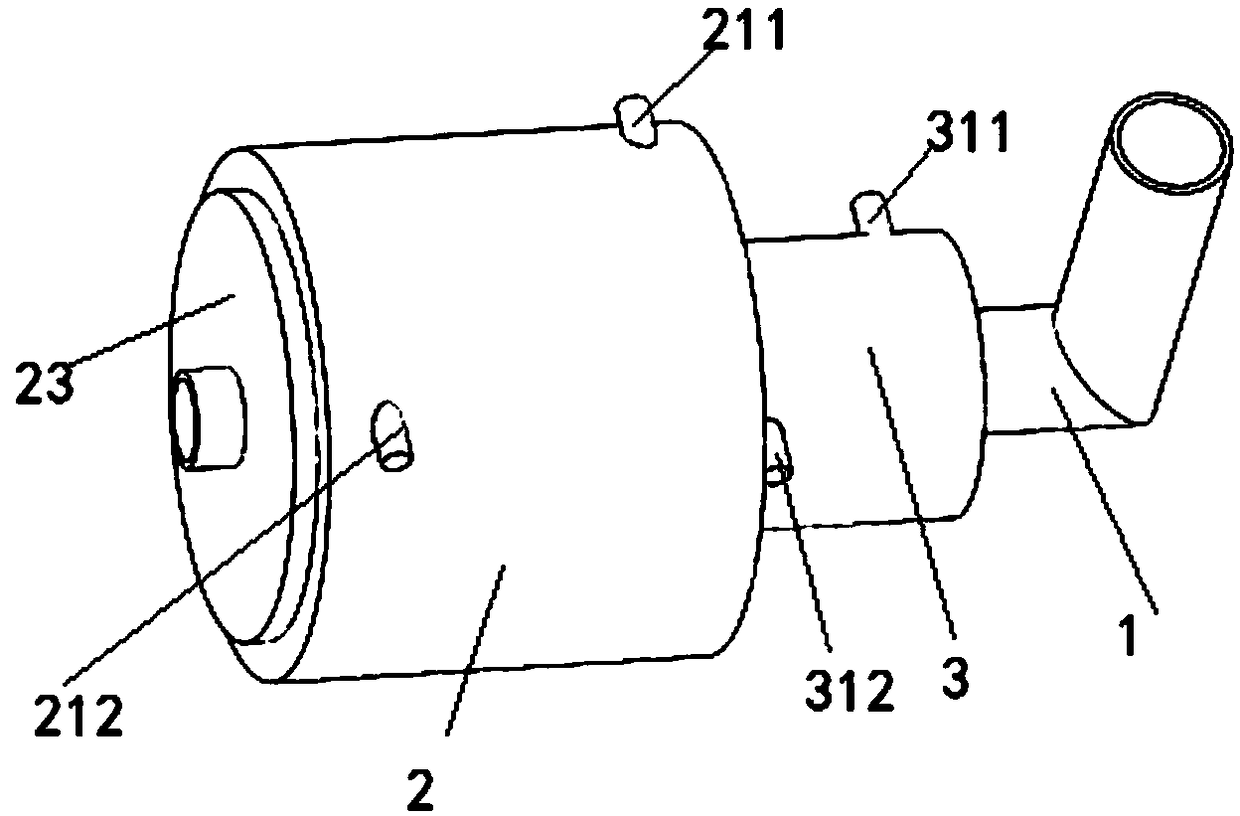

[0037] A high-efficiency energy-saving gas boiler, such as figure 1 , figure 2 As shown, it includes a gas furnace and a smoke outlet pipe 1 connected with the gas furnace, and the smoke outlet pipe 1 is provided with an amplified power generation mechanism 4;

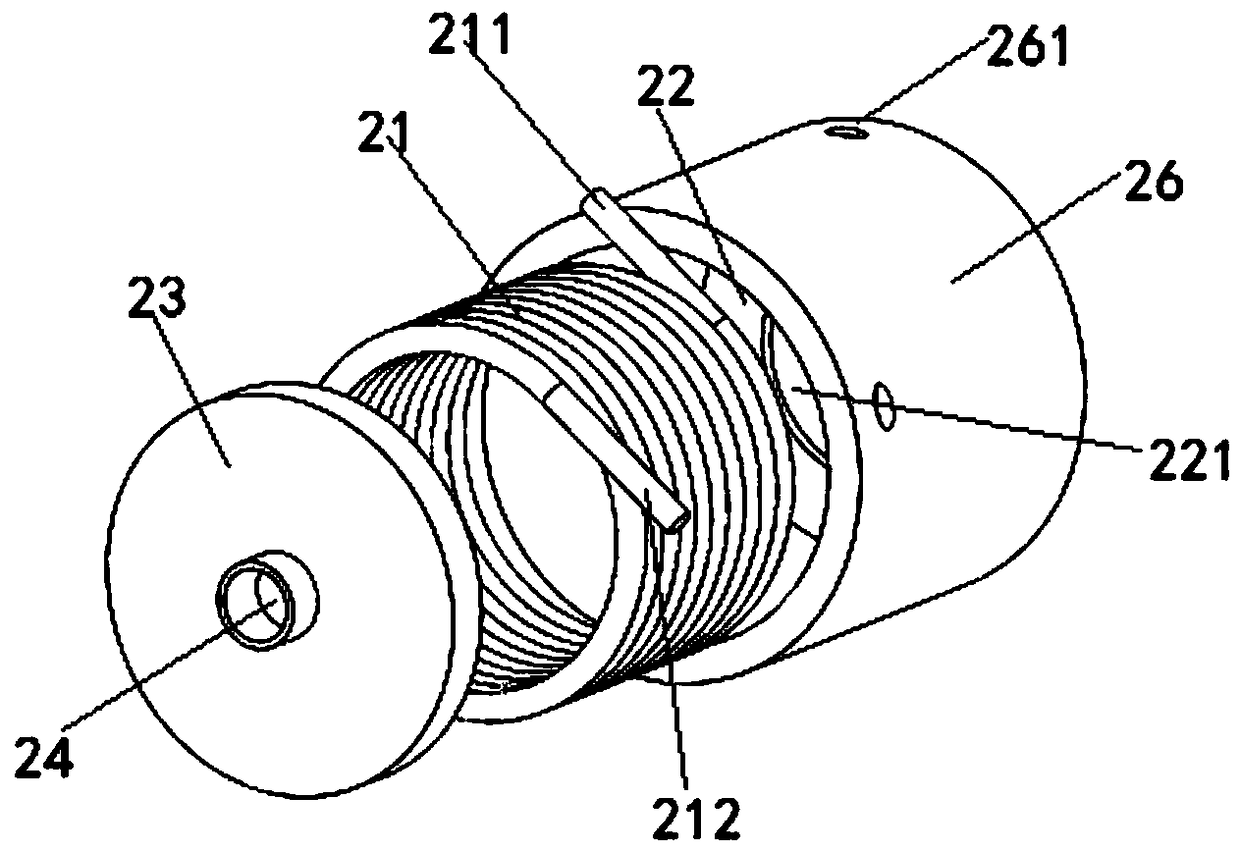

[0038]The gas furnace includes a combustion furnace 2 and a waste heat furnace 3 connected to each other. The inner surfaces of the side walls of the combustion furnace 2 and the waste heat furnace 3 are respectively sleeved with a first heating pipe 21 and a second heating pipeline 31. The second heating pipeline 31 The first water inlet pipe 311 is connected to the water inlet valve, the first water outlet pipe 312 of the second heating pipeline 31 is connected to the second water inlet pipe 211 of the first heating pipe 21 through a water pipe, and the second water outlet pipe 212 of the first heating pipe 21 is connected to Hot water outlet pipeline; water enters the second heating pipe 31 through the water inlet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap