Asymmetrical wedge-shaped vortex generator applied to flow control over compressor cascade and design method thereof

A vortex generator and cascade flow technology, applied in mechanical equipment, gas turbine devices, machines/engines, etc., can solve the problems of inability to efficiently reduce compressor flow loss, unreasonable structure, and weak compressor flow loss, etc. The effect of low total pressure loss, reduced airflow separation, and reduced form resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0027] An asymmetric wedge-shaped vortex generator method applied to flow control of a compressor cascade in this embodiment includes the following steps:

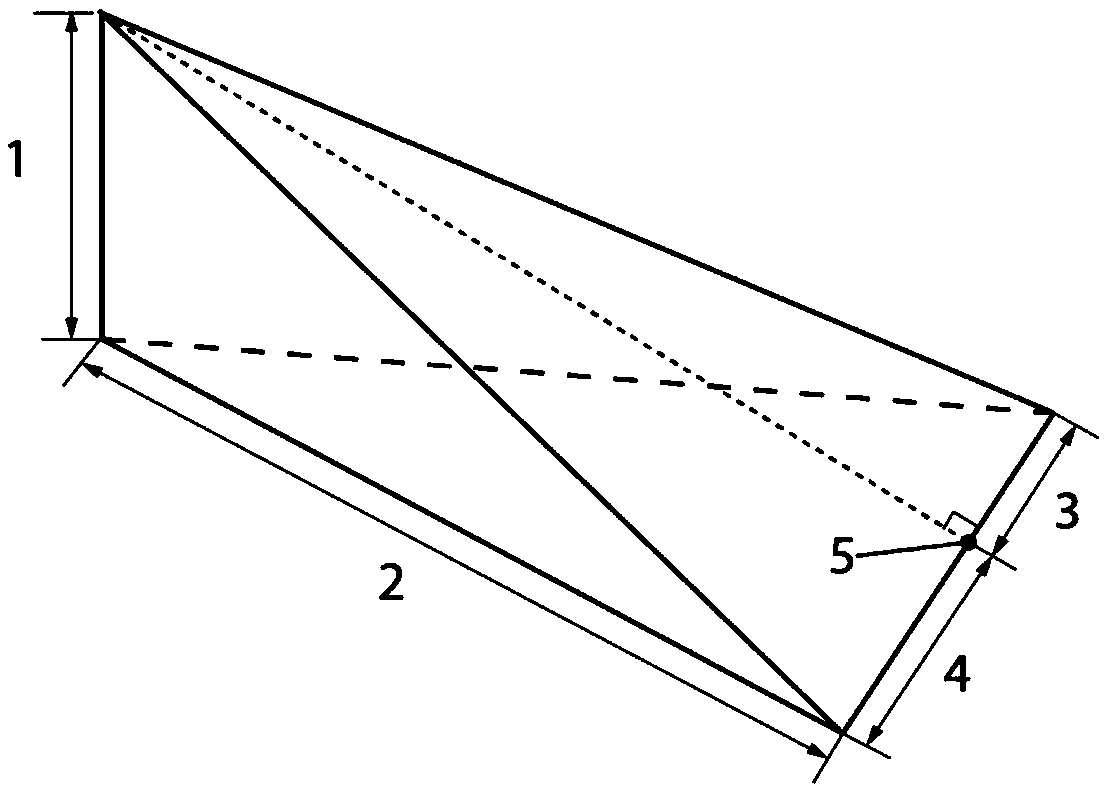

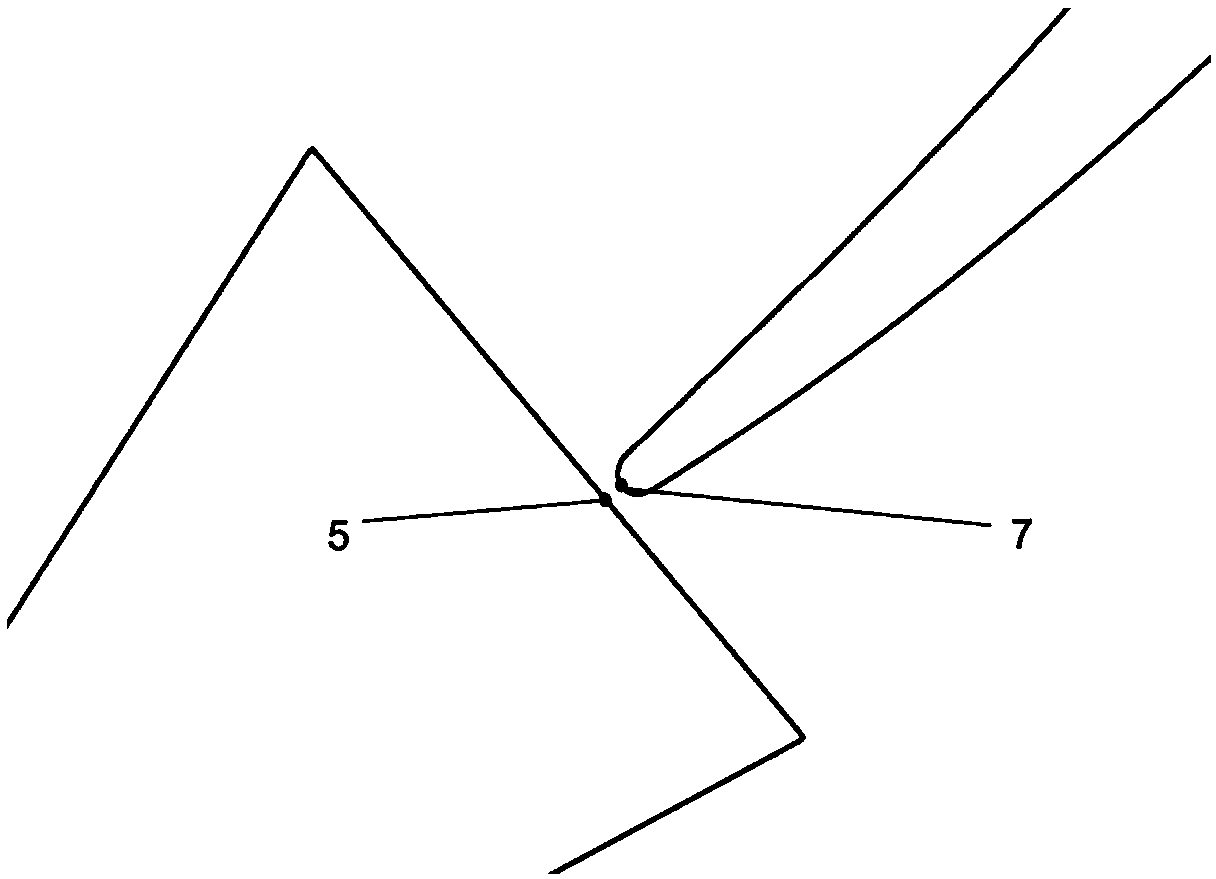

[0028] Step 1: Determine the design parameters of the geometric structure of the wedge-shaped vortex generator as radial height, axial length, suction side width and pressure side width. refer to figure 1 , the asymmetric wedge-shaped vortex generator has a tetrahedral structure as a whole. The geometric dimensions are determined by radial height 1, axial length 2, suction side width 3, and pressure side width 4. 5 is the vertical point of the bottom edge of the triangle on the top surface of the asymmetric wedge-shaped vortex generator. The radial height 1 is perpendicular to the bottom end wall.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial height | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com