Multiple casing pipe spliced screw pump

A screw pump and casing technology, applied in the field of screw pumps, can solve the problems of difficult splicing of screw pump tubes, prone to leakage, accumulation of large sludge at the inlet of screw pumps, etc., so as to reduce the probability of sludge blockage, increase firmness, and reduce deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

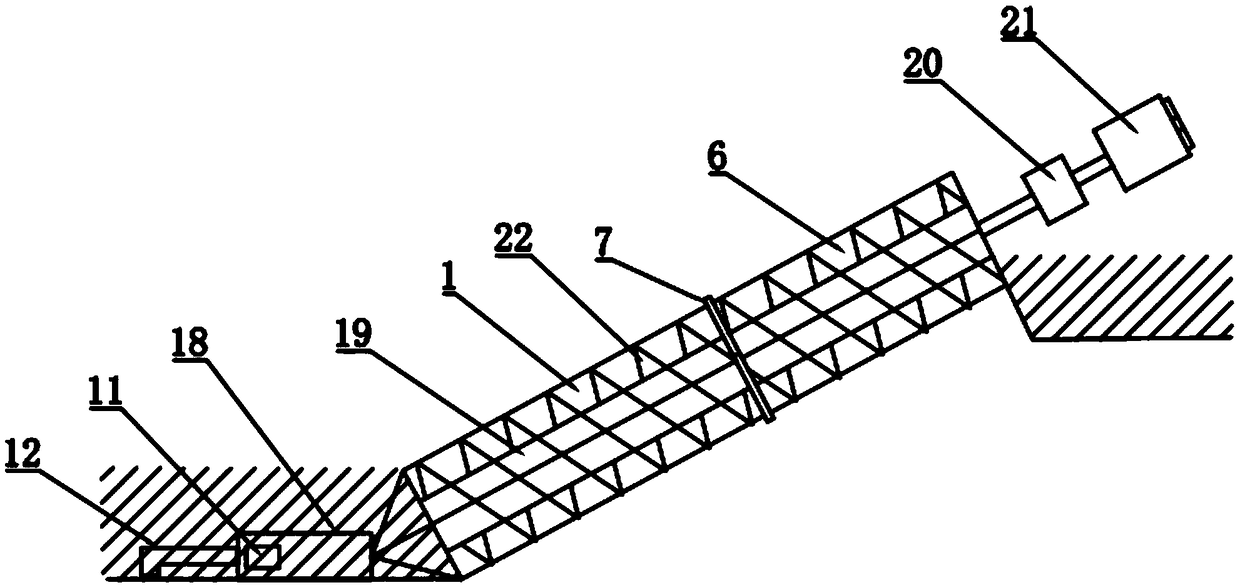

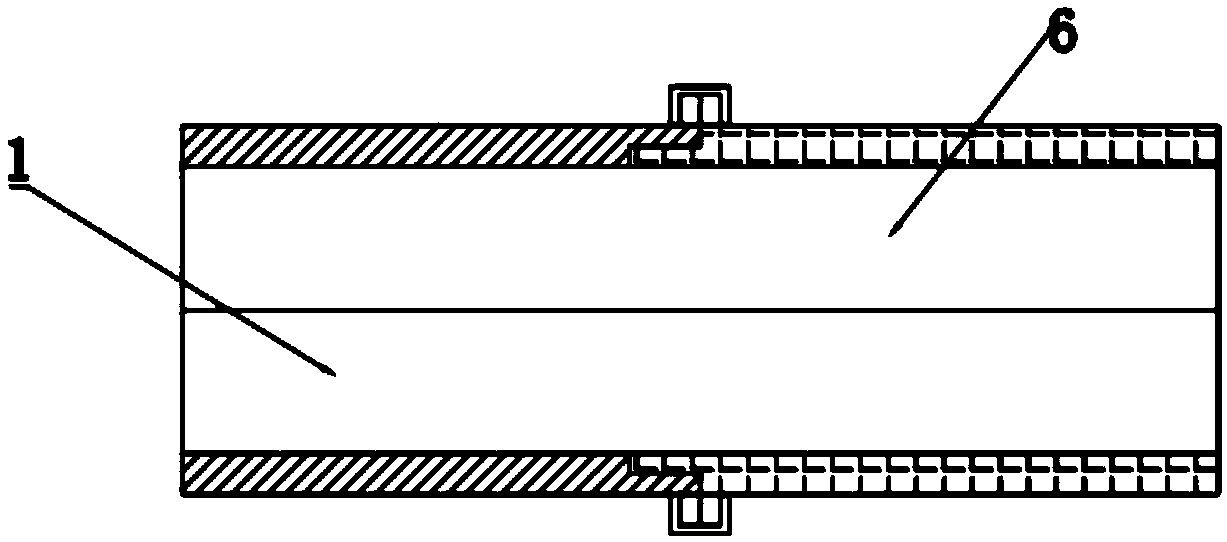

[0025] Such as figure 1 As shown, the screw pump with multiple sleeves spliced includes a left sleeve (1), a right sleeve (6), a screw (19), a reducer (20) and a motor (21), and the screw pump with multiple sleeves spliced A stirring device (18) is provided at the bottom, a screw (22) is provided on the screw rod (19), and the left sleeve (1) and the right sleeve (6) are connected together by snap rings (7). When the screw pump spliced with multiple sleeves needs to use multiple sleeves due to work, multiple left sleeves (1) and right sleeves (6) are spliced end to end to form a sleeve of sufficient length.

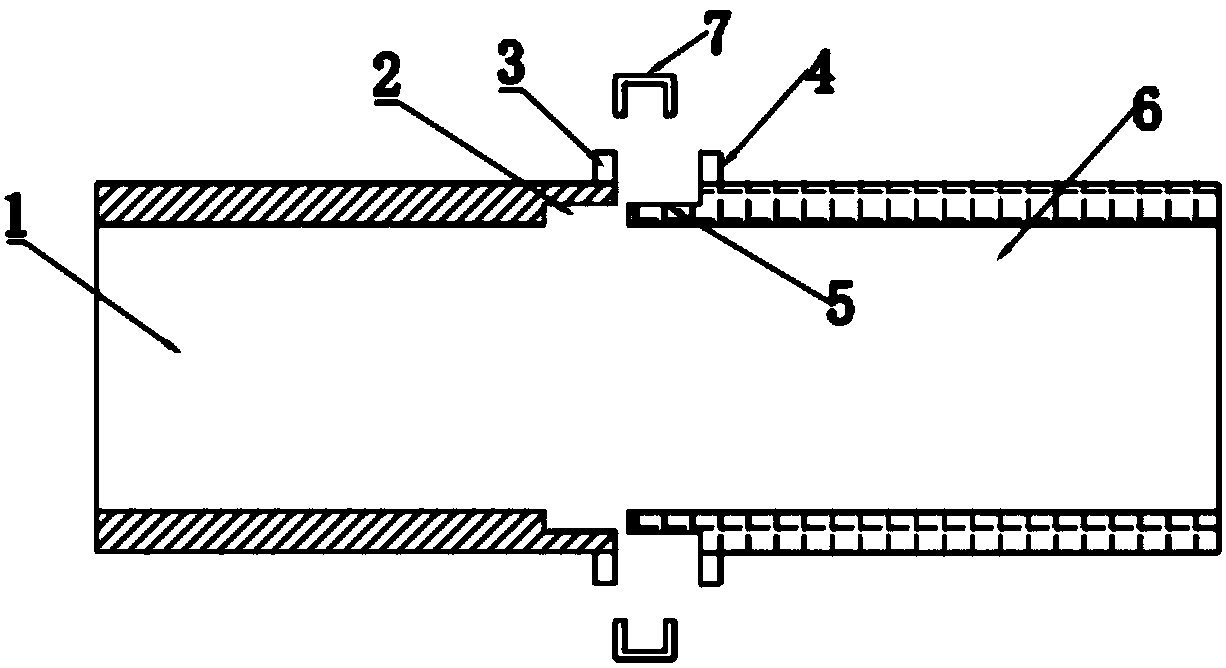

[0026] Such as figure 2 As shown, in order to quickly connect the left sleeve (1) and the right sleeve (6), a left connecting ring (3) is provided on the right side of the left sleeve (1), and the left connecting ring (3) The lower side is provided with a connecting groove (2) equivalent to half the wall thickness of the sleeve. The depth of the connecting groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com