Vibration-reducing buffer bearing

A technology for bearings and inner rings, applied in the field of vibration reduction and shock reduction bearings, can solve the problems of vibration reduction and shock reduction, etc., and achieve the effects of improving service life and stability, preventing wear and tear, and simple bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

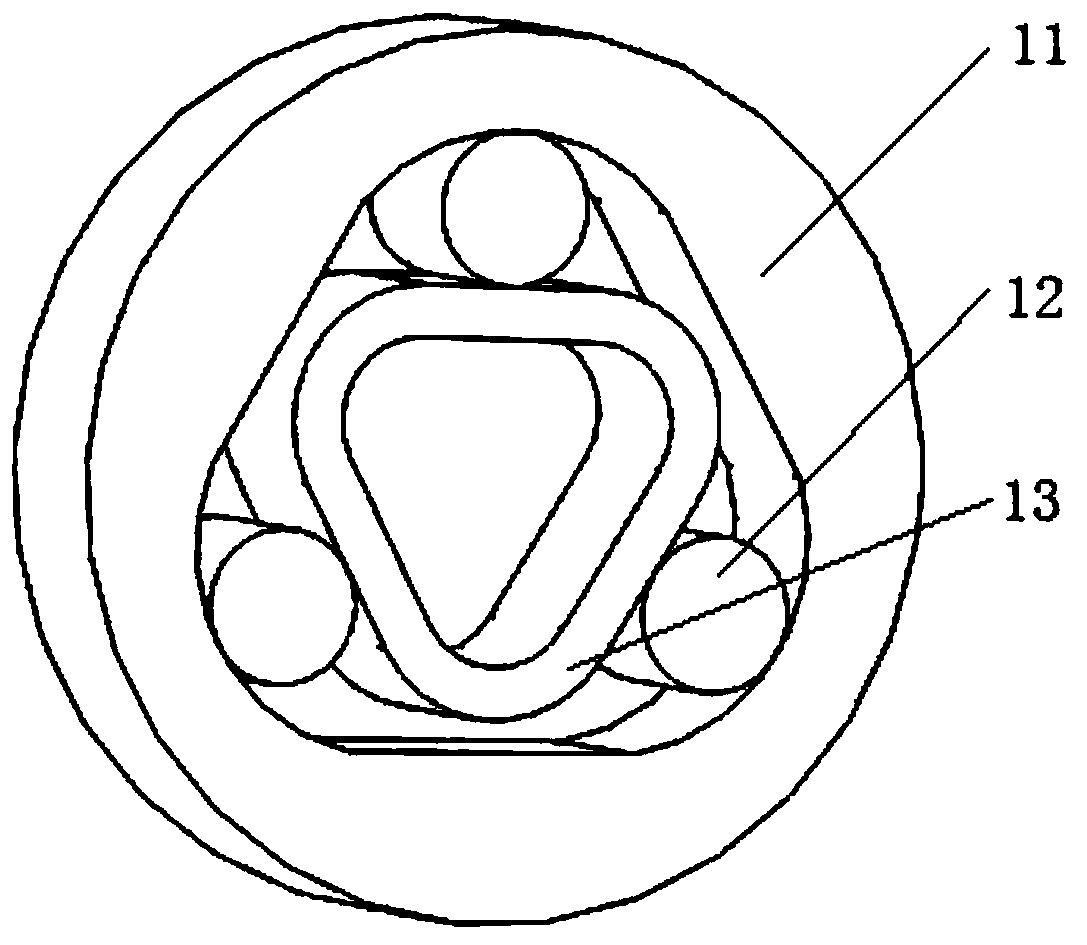

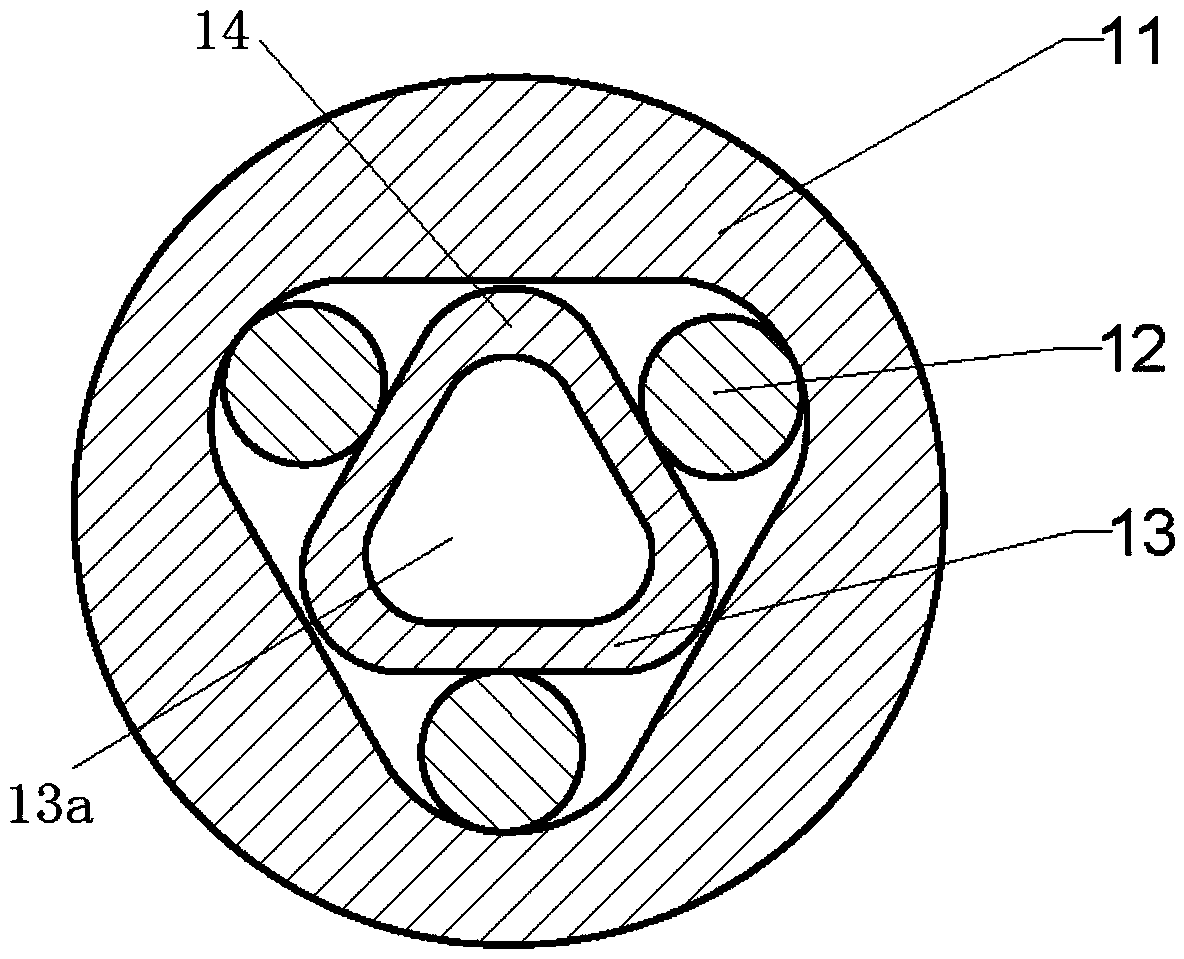

Embodiment 1

[0024] The vibration-reducing bearing of this embodiment includes an outer ring 11, an inner ring 13, and a plurality of rolling elements 12 arranged between the outer ring 11 and the inner ring 13, and the rolling elements 12 are made of flexible materials; the inner ring 13 is provided with a protrusion 14 protruding to the inner surface of the outer ring 11, and the adjacent rolling elements 12 are separated by the protrusion 14 to operate independently; the flexible material is preferably rubber, and it needs to have sufficient strength and at the same time not lose its elasticity; the rolling element 12 is preferably a cylindrical roller structure, and the contact area with the inner surface of the outer ring 11 is large, which is conducive to improving its supporting performance; the raised portion 14 can be integrally formed with the inner ring 13, thereby improving the 14 structural strength; the outer and inner surfaces both refer to the radial side.

[0025] The roll...

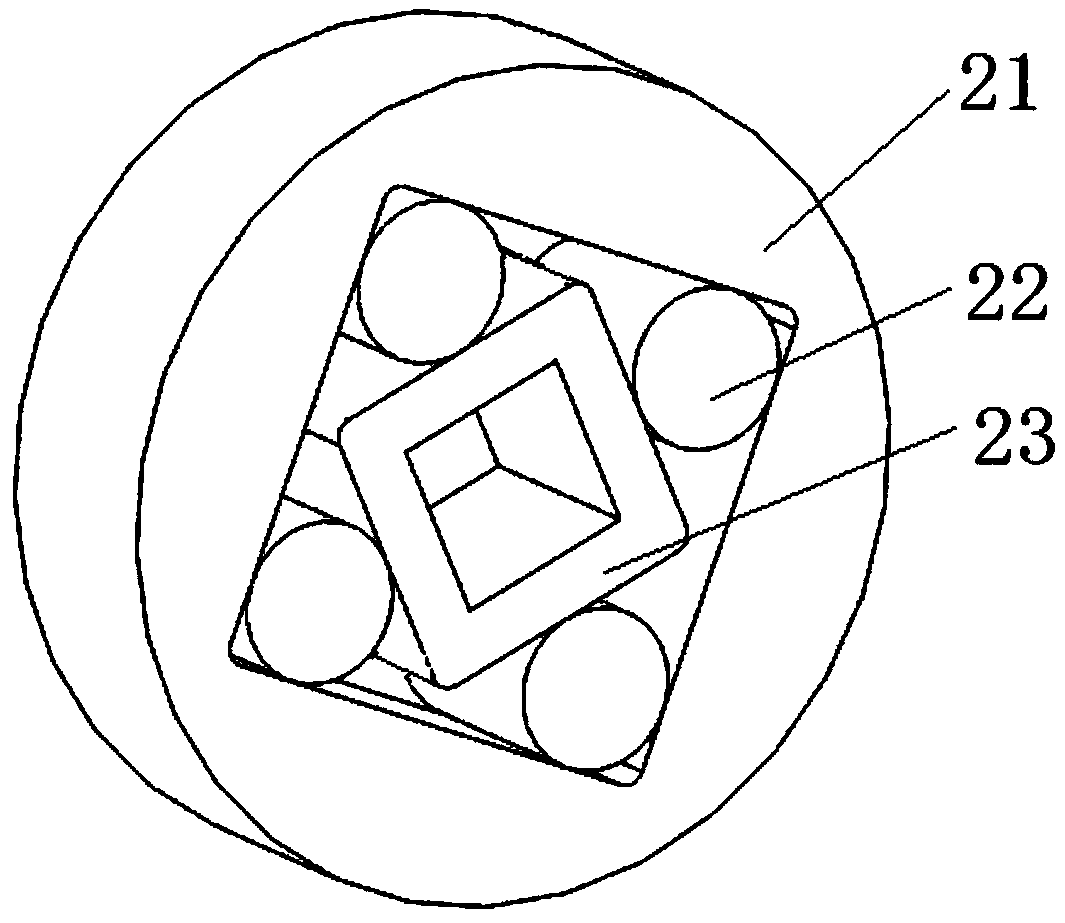

Embodiment 2

[0028] The vibration-reducing bearing of this embodiment includes an outer ring 21, an inner ring 23, and a plurality of rolling elements 22 arranged between the outer ring 21 and the inner ring 23, and the rolling elements 22 are made of flexible materials; the inner ring 23 is provided with a protruding part 24 protruding to the inner surface of the outer ring 21, and the adjacent rolling elements 22 are separated by the protruding part 24 to operate independently; the flexible material is preferably rubber, and it needs to have sufficient strength and at the same time not lose its elasticity; the rolling element 22 is preferably a cylindrical roller structure, and the contact area with the inner surface of the outer ring 21 is large, which is conducive to improving its supporting performance; the raised portion 24 can be integrally formed with the inner ring 23, thereby improving the 24 structural strength; the outer and inner surfaces both refer to the radial side.

[0029...

Embodiment 3

[0032] The vibration-reducing bearing of this embodiment includes an outer ring 31, an inner ring 33, and a plurality of rolling elements 32 arranged between the outer ring 31 and the inner ring 33. The rolling elements 32 are made of flexible materials; the inner ring 33 is provided with a protruding part 34 protruding to the inner surface of the outer ring 31, and the adjacent rolling elements 32 are separated by the protruding part 34 to operate independently; the flexible material is preferably rubber, and it needs to have sufficient strength and at the same time not lose its elasticity; the rolling element 32 is preferably a cylindrical roller structure, and the contact area with the inner surface of the outer ring 31 is large, which is conducive to improving its supporting performance; the raised portion 34 can be integrally formed with the inner ring 33, thereby improving the 34 structural strength; the outer and inner surfaces both refer to the radial side.

[0033]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com