Drum type cotton drying equipment

A drying equipment and a drum-type technology, applied in the field of drum-type cotton drying equipment, can solve the problems of poor drying quality of cotton balls that cannot meet standards, uneven drying and blowing of cotton balls, blocking drying wind circulation, etc. The effect of reducing the difficulty of loading and unloading operations, good butt sealing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

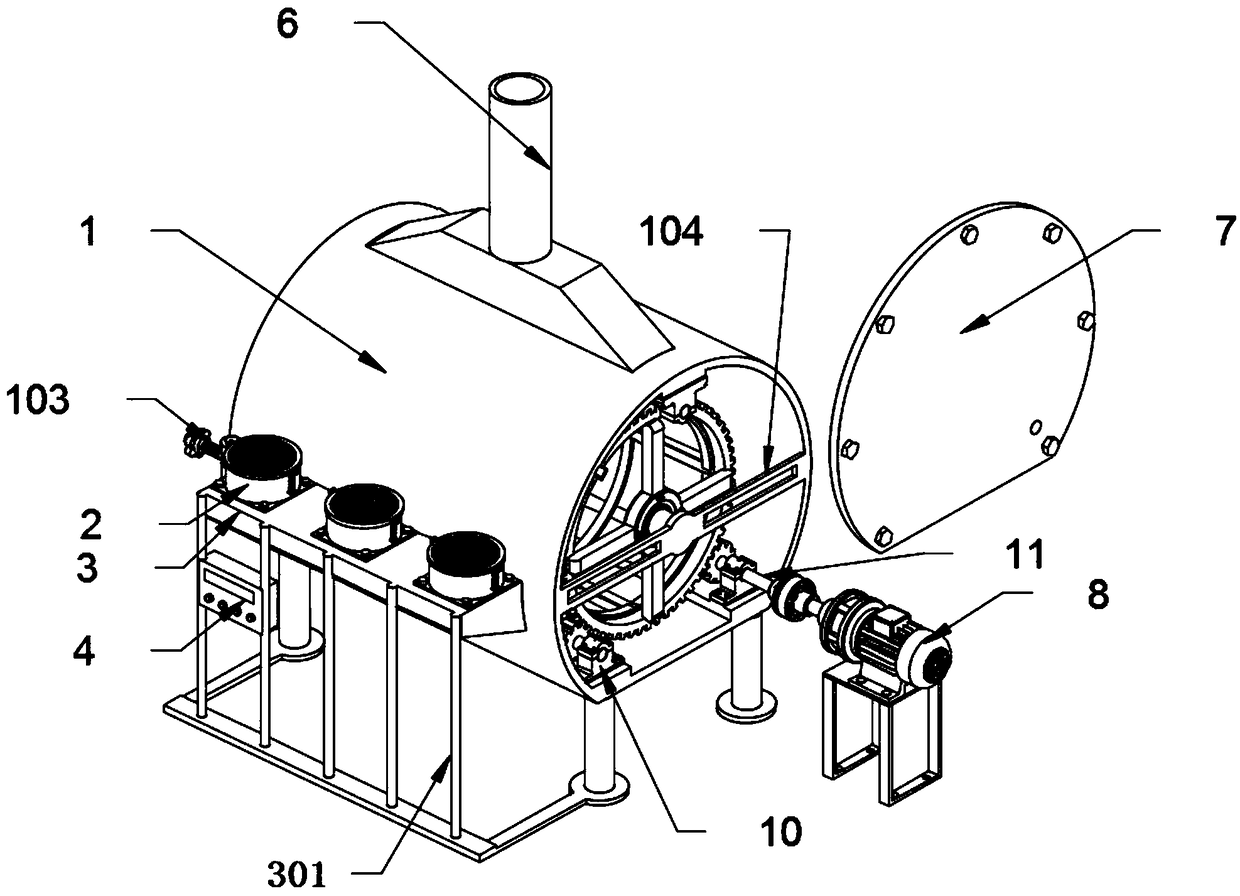

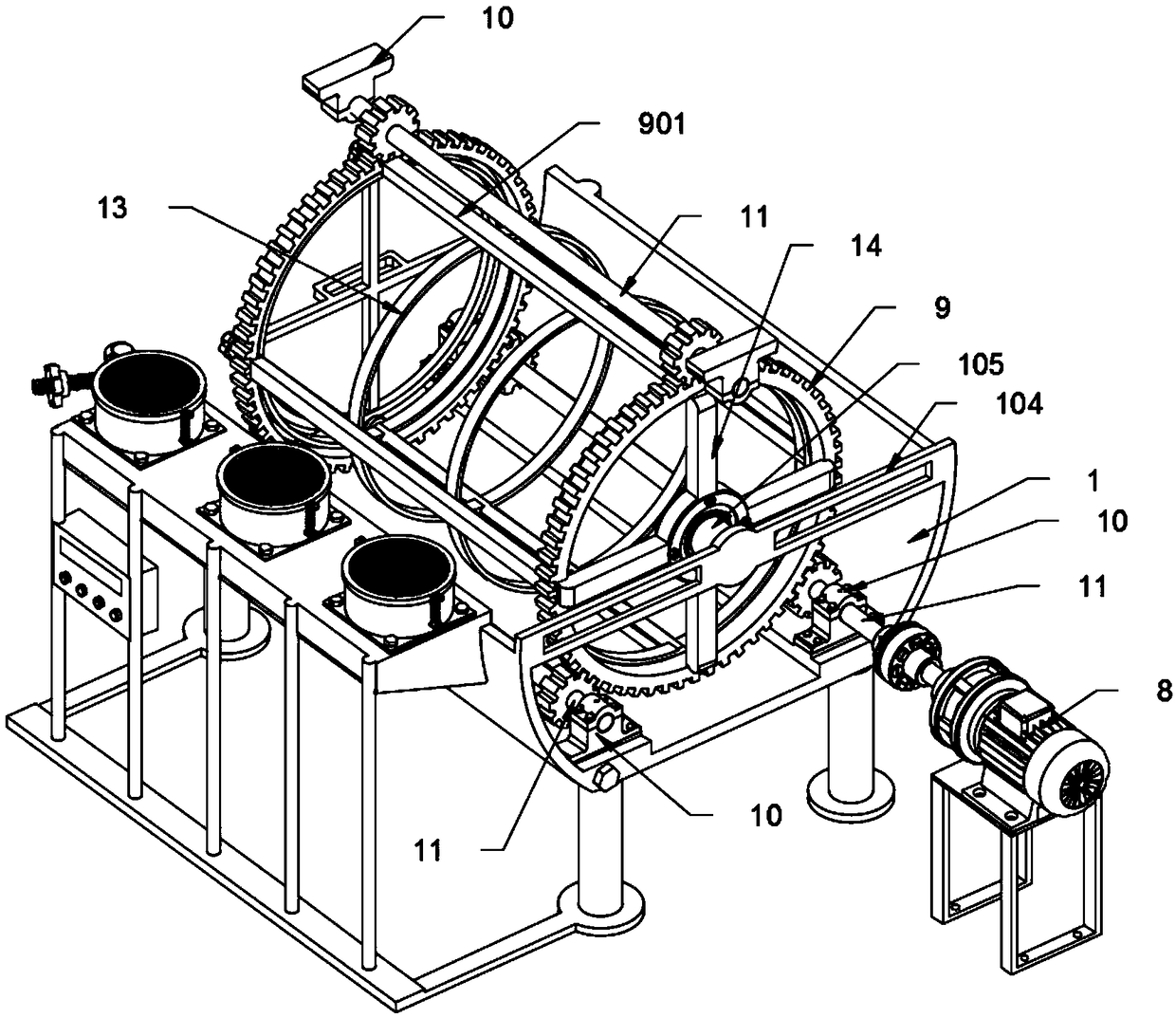

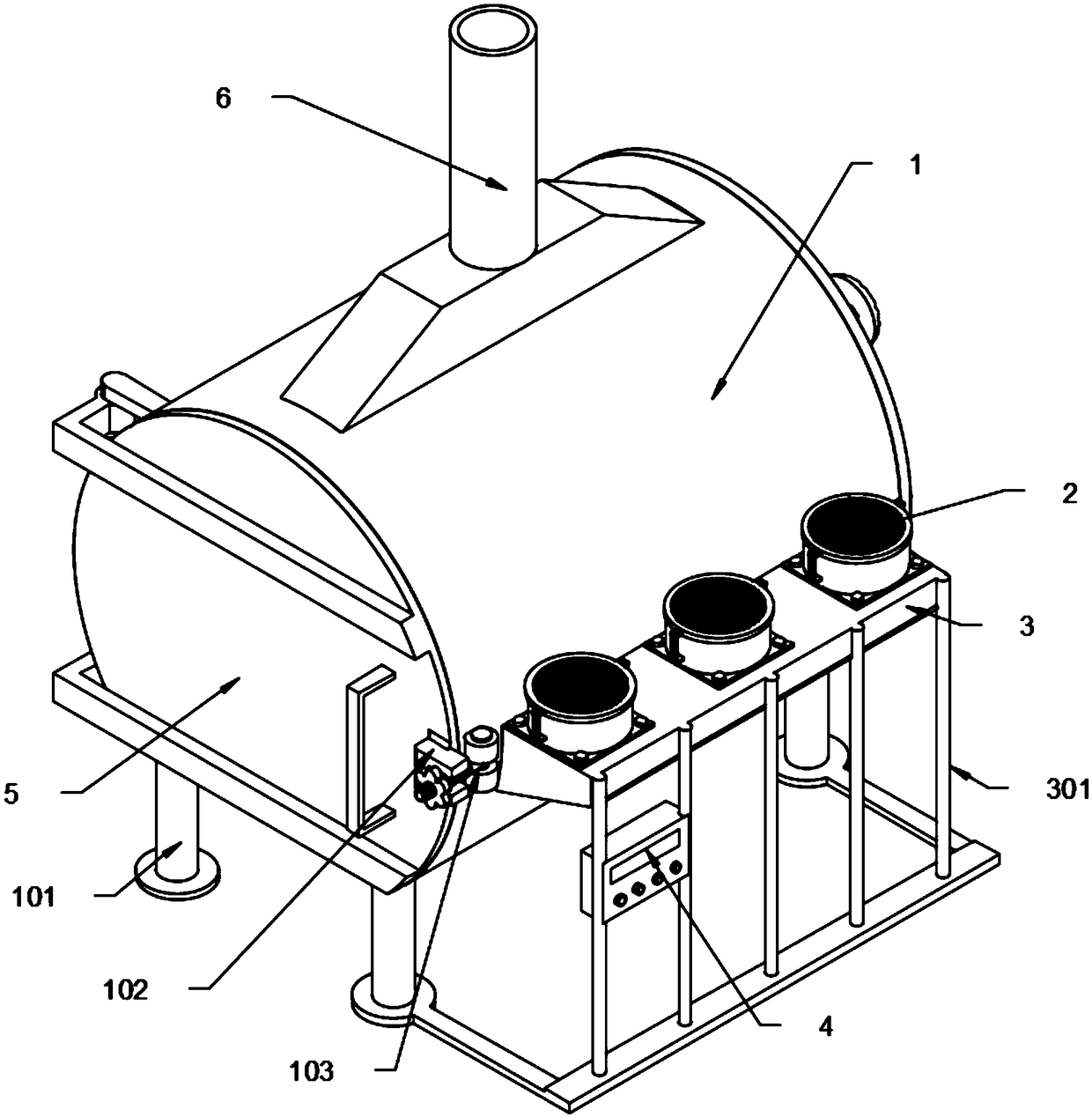

[0044] as attached figure 1 to attach Figure 13 Shown:

[0045] The invention provides a drum-type cotton drying equipment, which includes a drying box 1, a support leg 101, a buckle plate 102, a locking bolt 103, a positioning frame 104, a positioning shaft 105, an electric heating fan 2, a fan filter 201, a pull Tight spring 202, bellows 3, bellows support rod 301, control electric box 4, box door 5, air outlet pipe 6, drying box rear baffle 7, drive motor 8, rolling frame 9, support chute 901, bearing seat 10 , a rotating shaft 11, a gear 111, a bucket cover 12, a cotton bucket 13 and a fixed frame 14, the whole of the drying box 1 is arranged in a cylindrical bottom plane cut, and a box door 5 is hinged in its front rotation, and its rear end There is a box rear baffle 7 for screw locking and sealing; the bottom of the flat bottom plate of the drying box 1 is symmetrically supported by four supporting legs 101; Pipe 6, and a bellows 3 is welded and connected on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com