A method for measuring bearing rolling friction torque

A rolling friction force and measurement method technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as difficult measurement or accurate bearing friction torque, achieve convenient and fast loading and unloading, and reduce the use of cost, the effect of improving measurement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. According to the measurement range of the sensor 2 and the radial loading range of the bearing 7, check and set the appropriate data acquisition and processing system measurement channel gear, so that the measurement signal with the output value of the sensor 2 within the entire measurement range has a better signal-to-noise ratio;

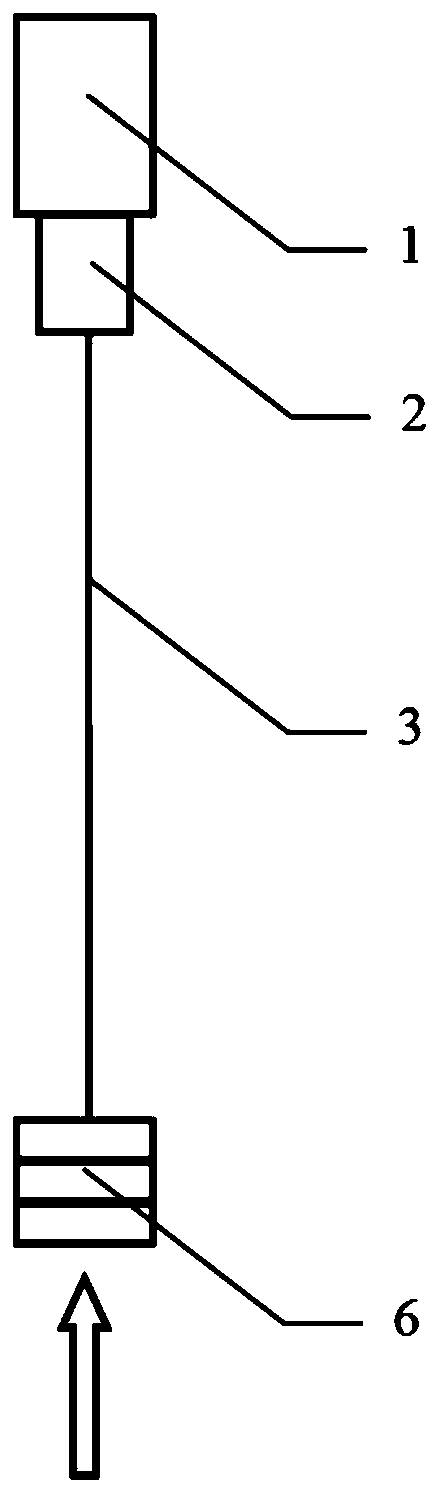

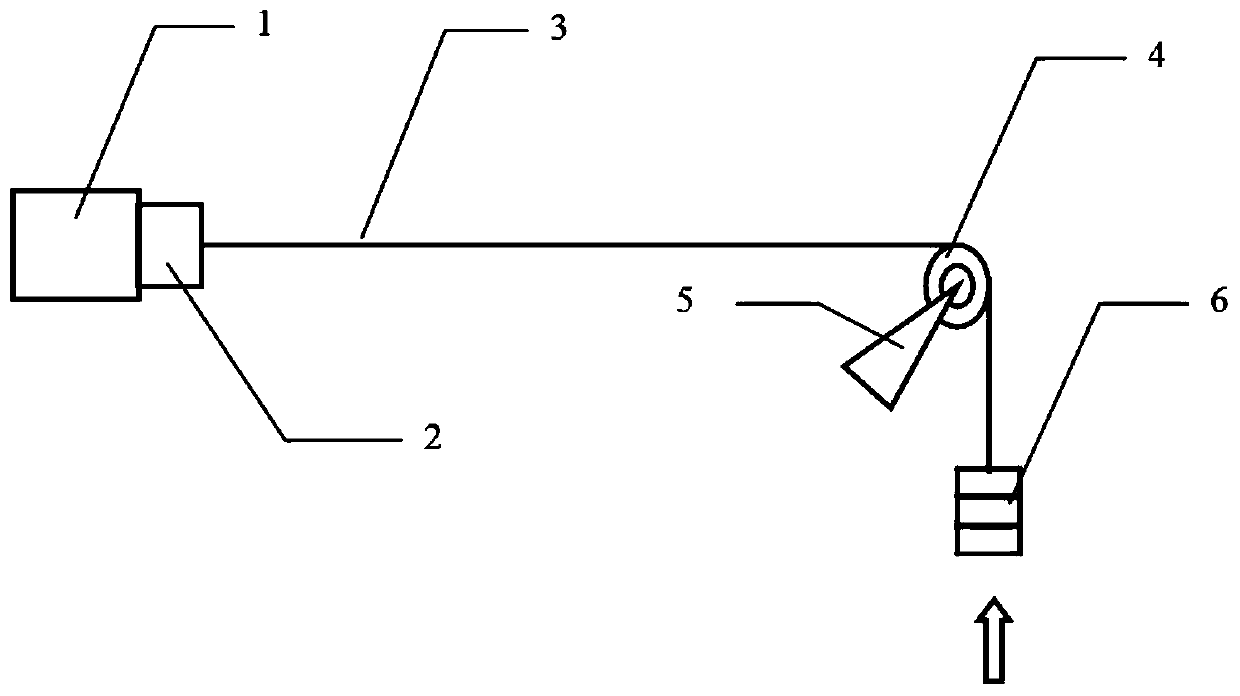

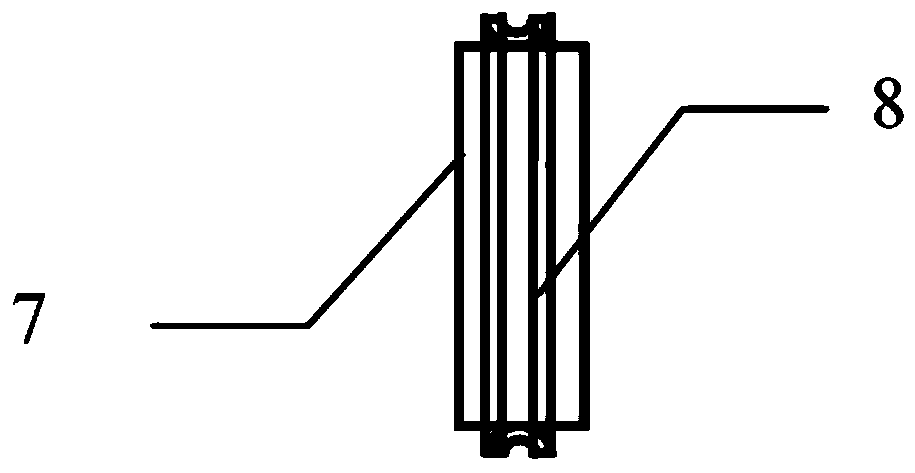

[0051] 2. Press figure 1 As shown, the sensor 2 is installed vertically, and the sensor mounting seat 1 and the sensor 2 are adjusted to ensure that the force-feeling axis of the sensor 2 is coaxial with the loading line 3. It adopts high-strength, low-elasticity, and small contact-sliding with the bearing jacket 8 The soft wire is used as the loading line 3, one end of the loading line 3 is fixed on the sensor 2, and the other end is suspended on the weight 6 that has been accurately measured and weighed; the weight 6 is quickly lifted up by manual or mechanical devices within 30ms , realize fast unloading, check the triggering situatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com