Dedicated clamp for neutron small-angle scattering high-temperature in-site tensile test

A small-angle scattering and in-situ stretching technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve accurate test results, reduce the difficulty of disassembly and assembly, and facilitate disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0023] In order to further clarify the technical advantages of the present disclosure, it will be described in detail in conjunction with the examples, the specific examples are as follows:

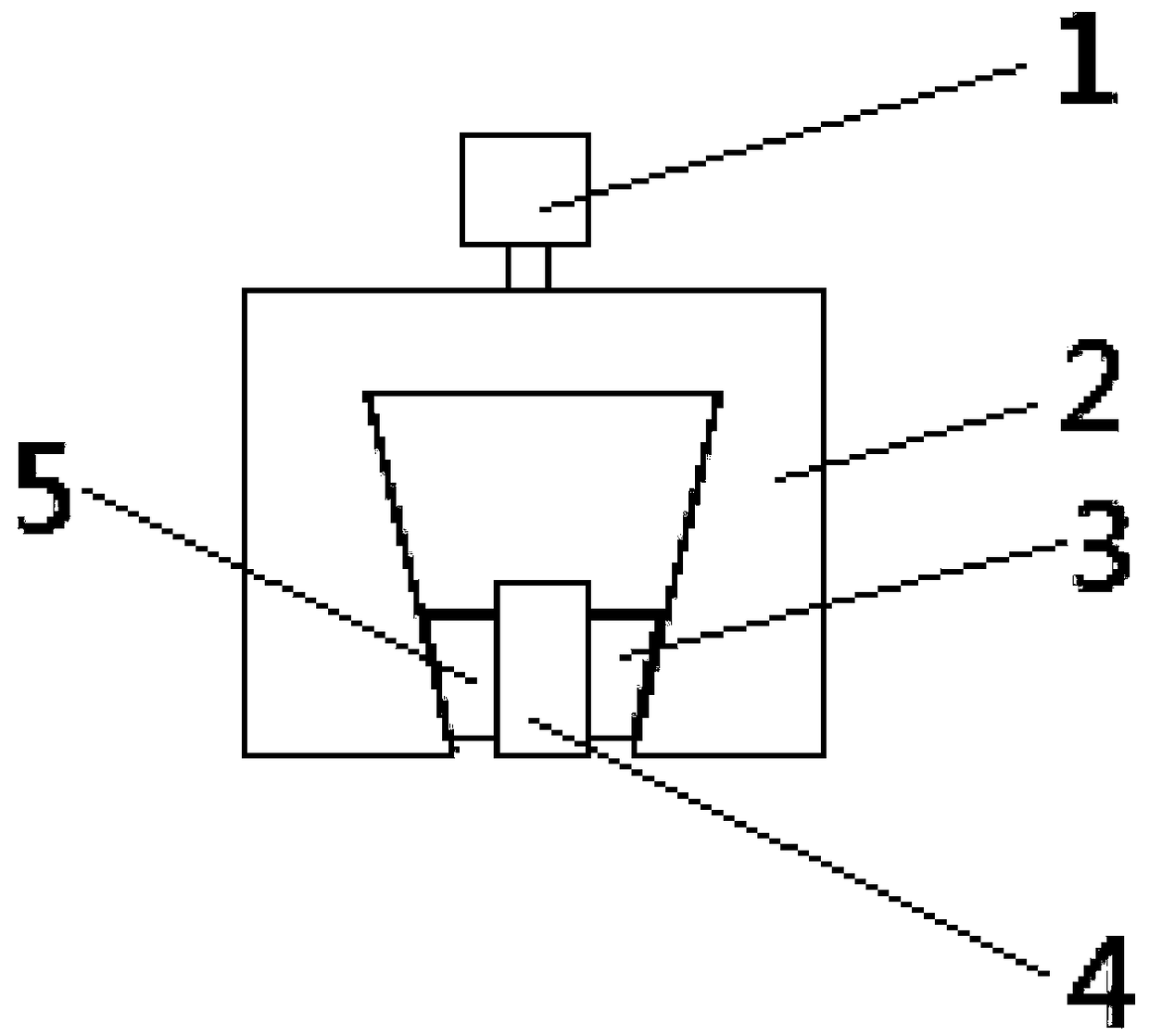

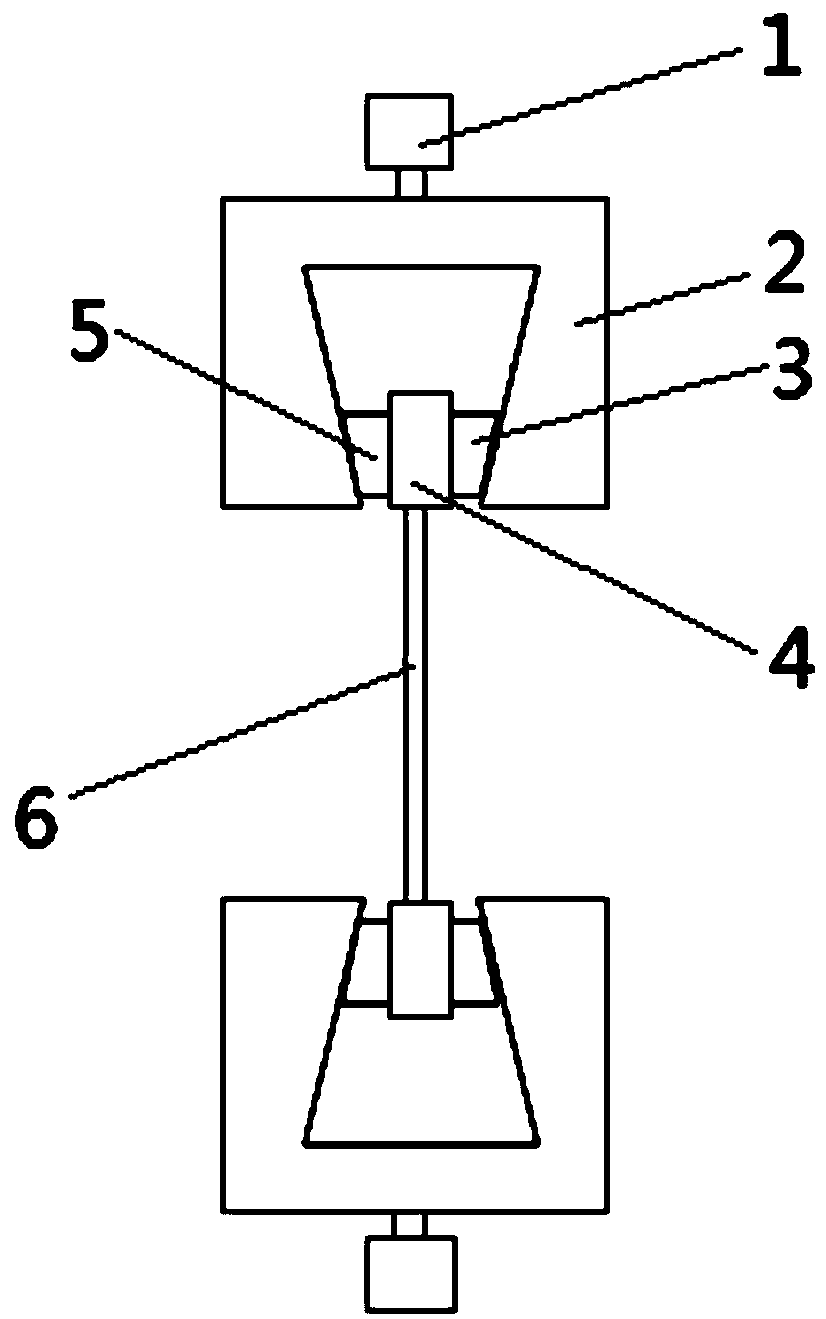

[0024] The clamp of the present disclosure includes: a chuck bolt 1, a chuck body 2, and a sample fixing assembly; wherein the chuck bolt 1 is fixed on the chuck body 2 through threaded connection, the chuck body 2 is provided with a trapezoidal opening, and the trapezoidal opening The upper bottom edge of the trapezoid faces outward, thus presenting a trapezoidal opening with a large inside and a small outside; the trapezoidal slope opening is used in the chuck body, and it is locked with the left and right fixed wedge clamps; and the greater the pulling force, the left and right The greater the horizontal thrust of the fixed wedge-shaped clamps 5 and 3, the greater the horizontal thrust, the greater the horizontal pressure on the sample, so that the test fixture clamps the test sample mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com