Automatically isolated security injection tank

An injection box, automatic technology, applied in the direction of climate sustainability, reactors, greenhouse gas reduction, etc., can solve the problems of safety injection function failure, affecting the safety of the core, etc., to enhance safety, avoid isolation failure, applicability and promotional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

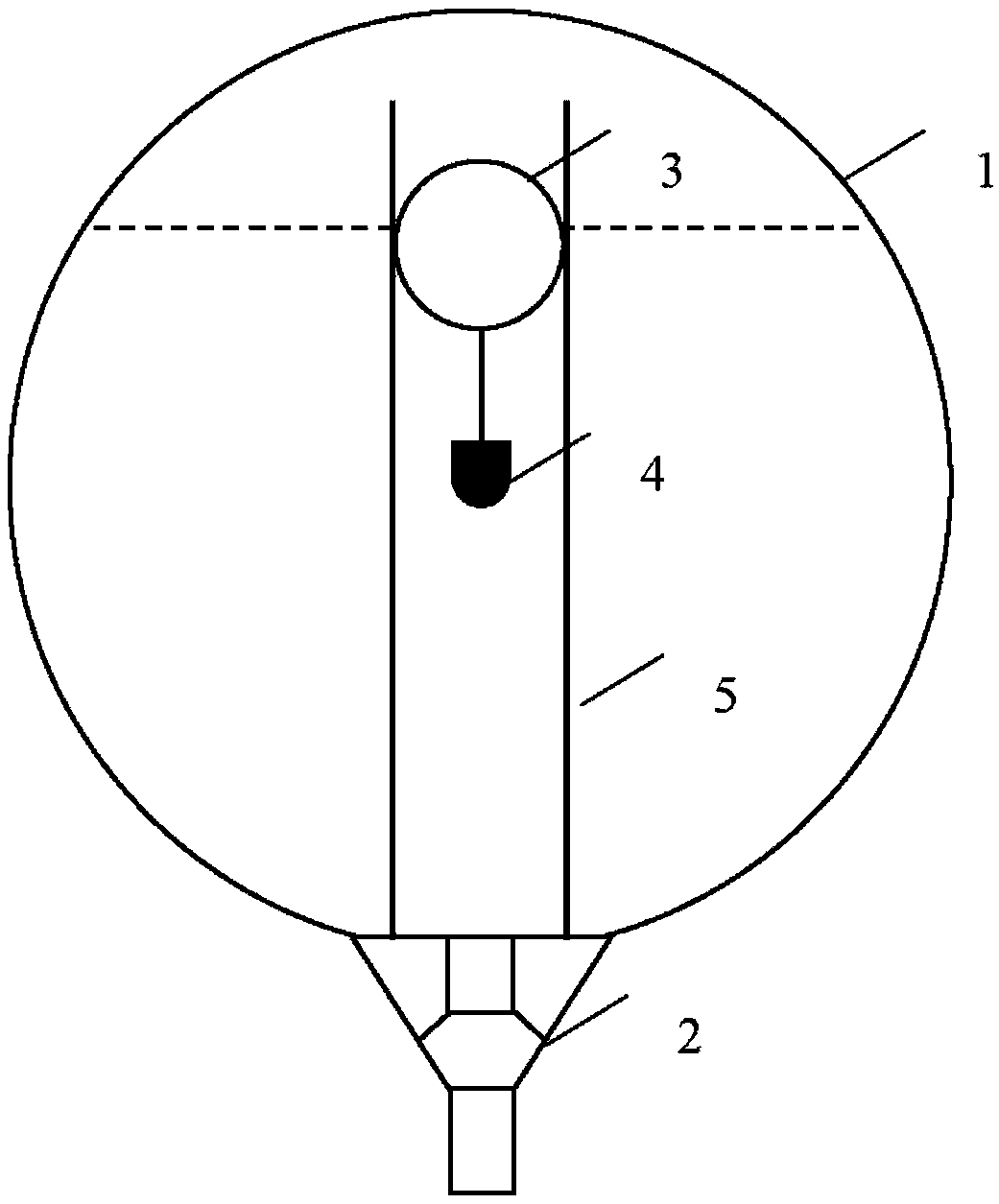

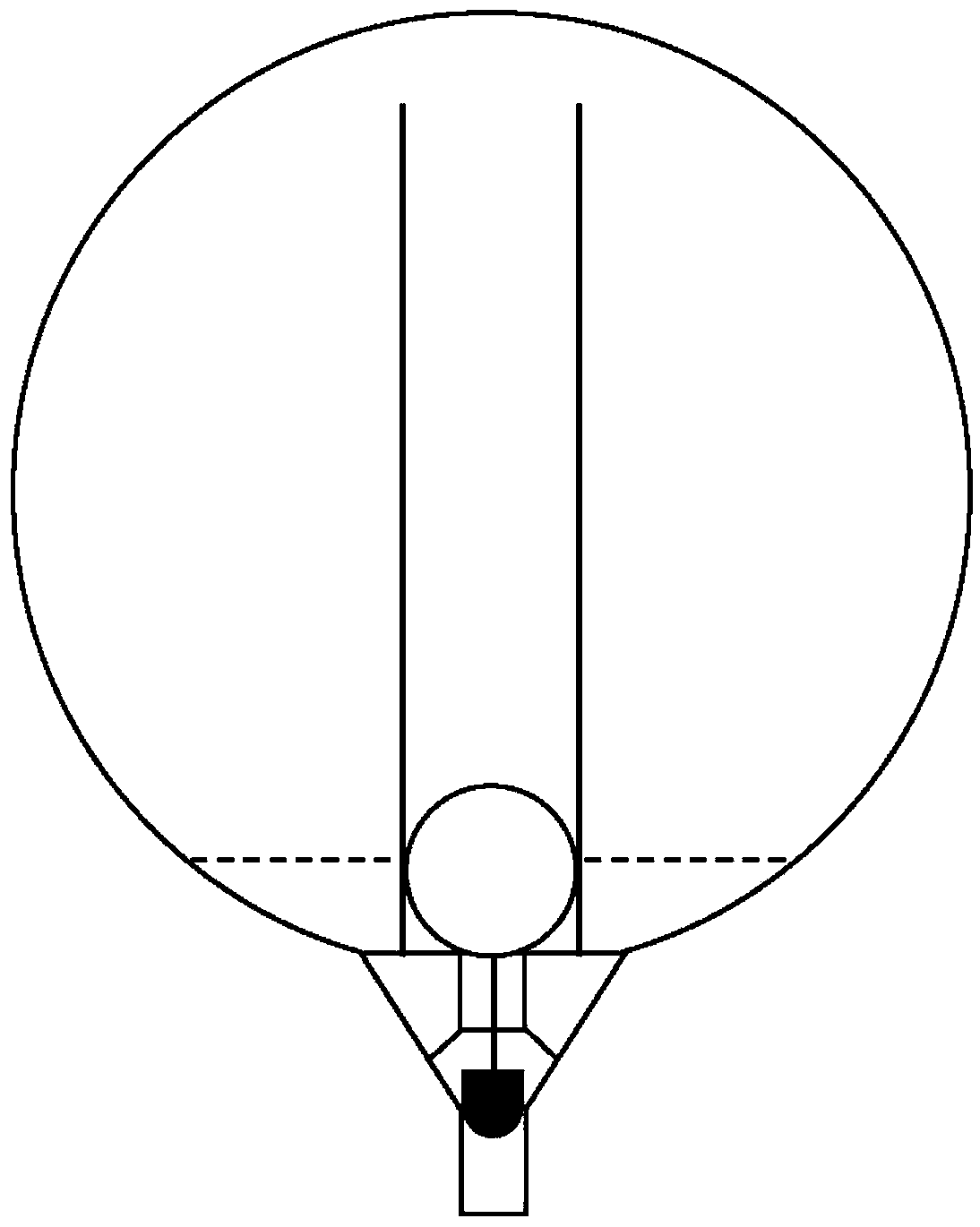

[0033] The composition structure of the exemplary self-isolated safety injection tank of the present invention is as follows: Figure 1-2 As shown, it includes an injection box 1, an outlet nozzle 2, a float ball 3, an isolation plug 4, and a guide rod 5.

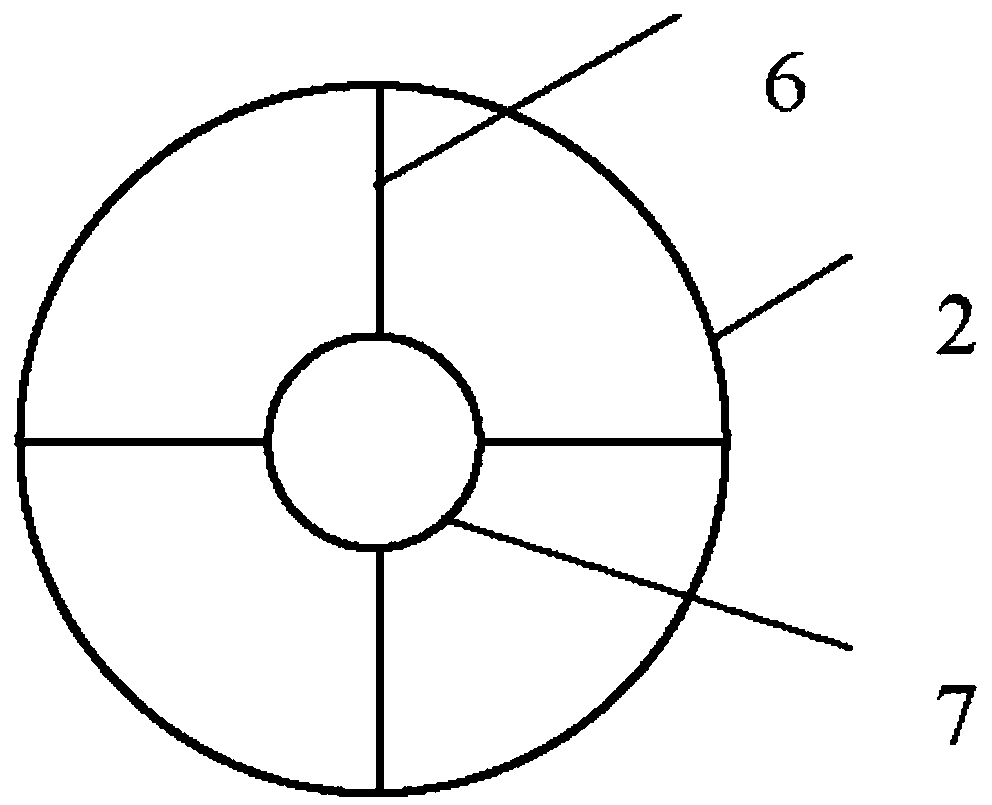

[0034] The outlet nozzle 2 is trumpet-shaped, with a large opening at the upper end and a small opening at the lower end, which is arranged below the safety injection box 1 and connected with the safety injection box 1, and is used for spraying the coolant in the safety injection box 1. The outlet nozzle 2 includes a center cylinder 7 arranged at its radially central position, for the isolation plug 4 to drop into it to block the coolant outlet of the safety injection tank 1 . The outlet nozzle 2 also includes a baffle 6 arranged radially along its inside for eliminating the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com