An automatic unloading automobile wheel hub painting device

A technology of automobile wheel hub and automatic unloading, which can be applied in the direction of injection device, etc., can solve the problems of low production efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

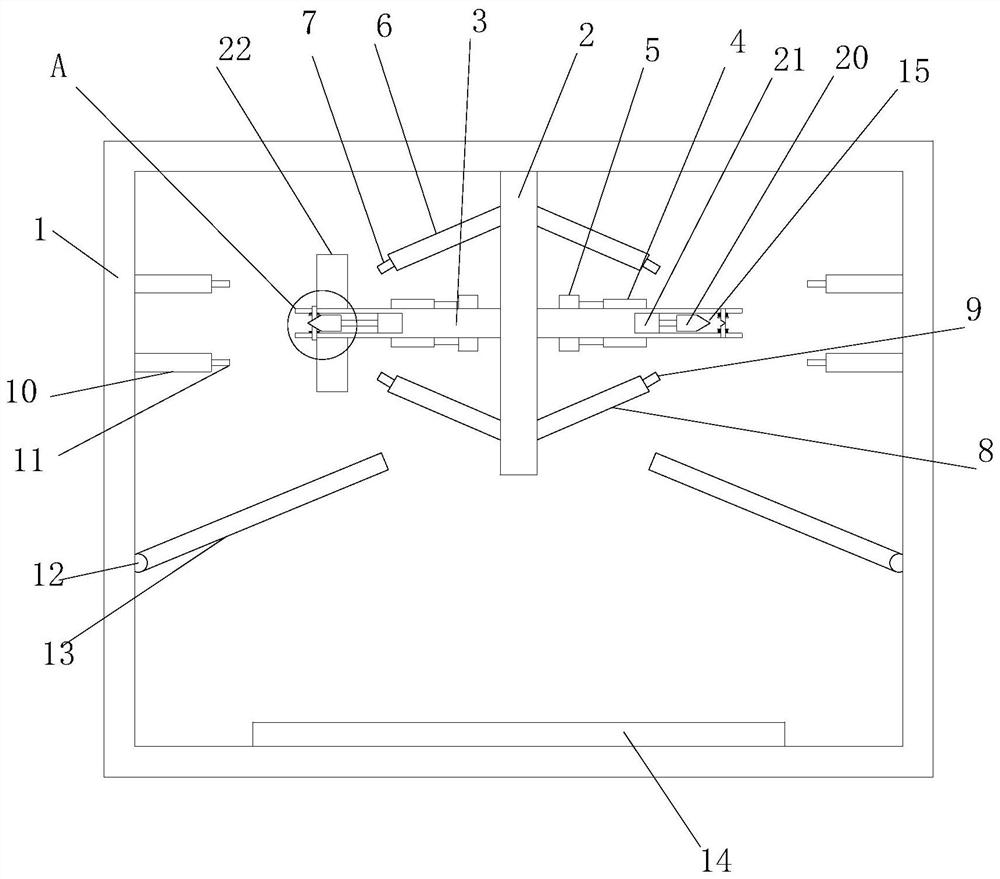

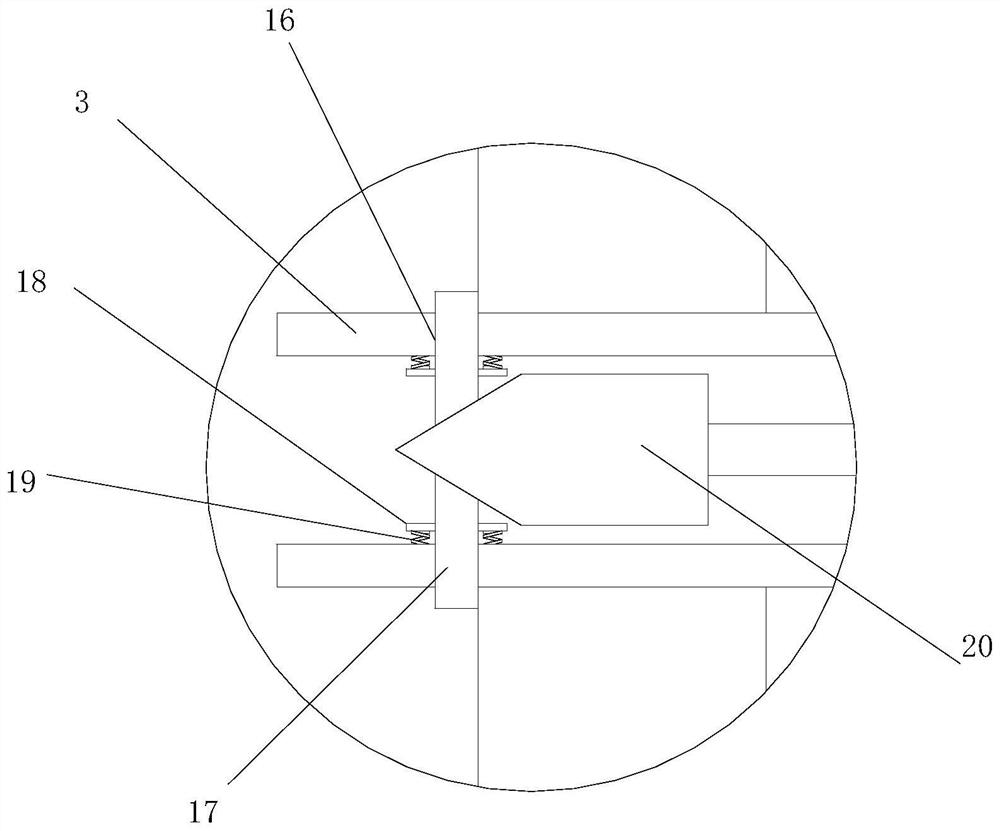

[0012] Such as figure 1 , figure 2 as shown, figure 1 It is a structural schematic diagram of an automatic unloading automobile wheel hub painting device proposed by the present invention; figure 2 for figure 1 The schematic diagram of the enlarged structure in A.

[0013] refer to figure 1 , figure 2 , the present invention proposes a kind of automatic unloading automobile hub painting device, comprises painting box 1, control mechanism and timer, wherein:

[0014] The paint spray box 1 is provided with a vertical arrangement and installed on the installation shaft 2 at the top of the paint spray box 1, and horizontally arranged support rods 3 for supporting workpieces to be processed are installed on both sides of the installation shaft 2. The support rod 3 is provided with a first For the weight sensor, a plurality of pusher assemblies are arranged on the outer circumference of the support rod 3, and the pusher assembly includes a push rod 4 and a first drive mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com