Pipeline inner wall maintenance machine with cleaning and paint spraying functions

A technology for maintaining machines and pipes, which is applied in spray booths, cleaning hollow objects, cleaning methods and utensils. the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

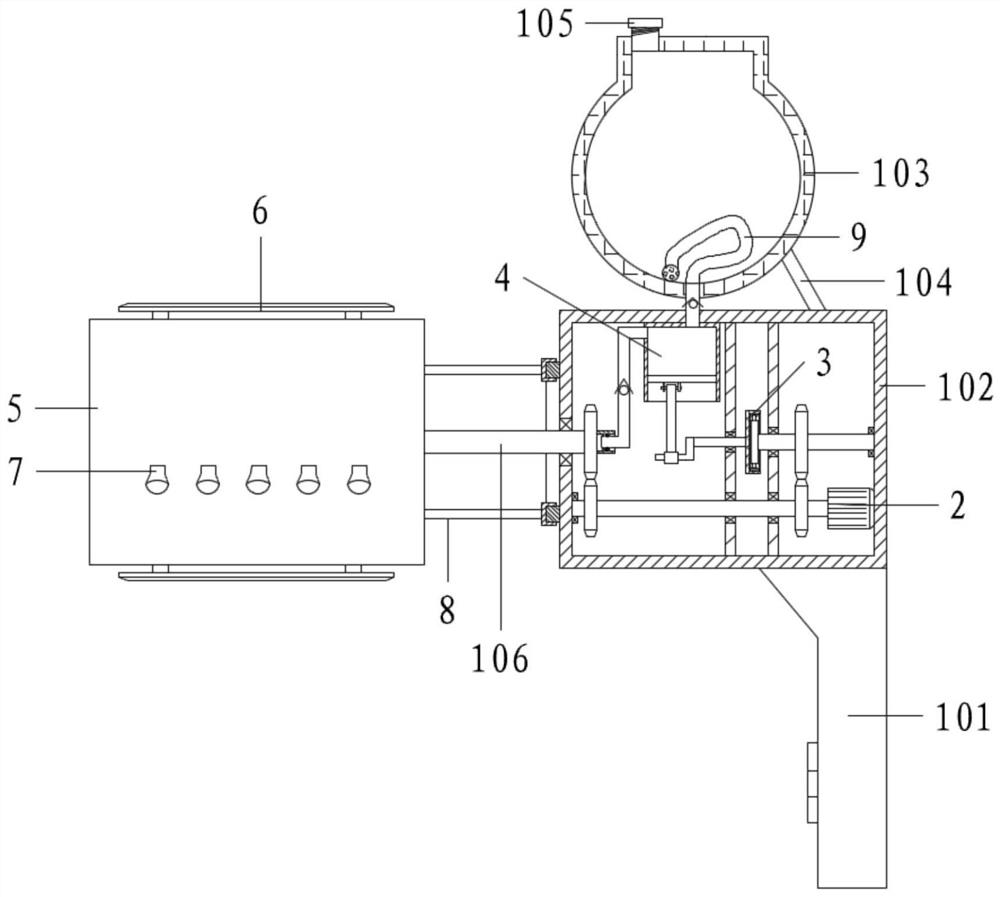

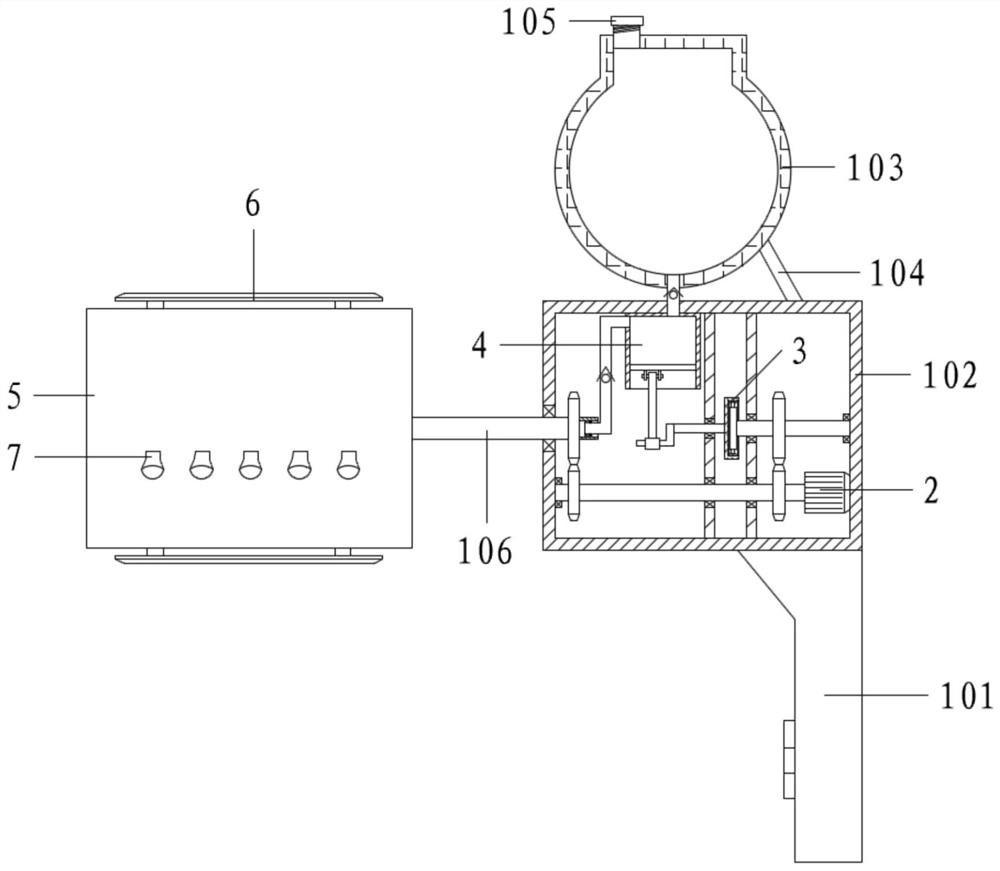

[0066] Referring to the accompanying drawings, a pipeline inner wall maintenance machine with cleaning and painting functions includes a handle 101, a power box 102, a paint storage tank 103, a fixed rod 104, a sealing cover 105 and a main shaft 106;

[0067] The top of the handle 101 is fixed with a power box 102; the paint storage tank 103 is connected above the power box 102 through a fixed rod 104, and the top of the paint storage tank 103 is screwed with a sealing cover 105;

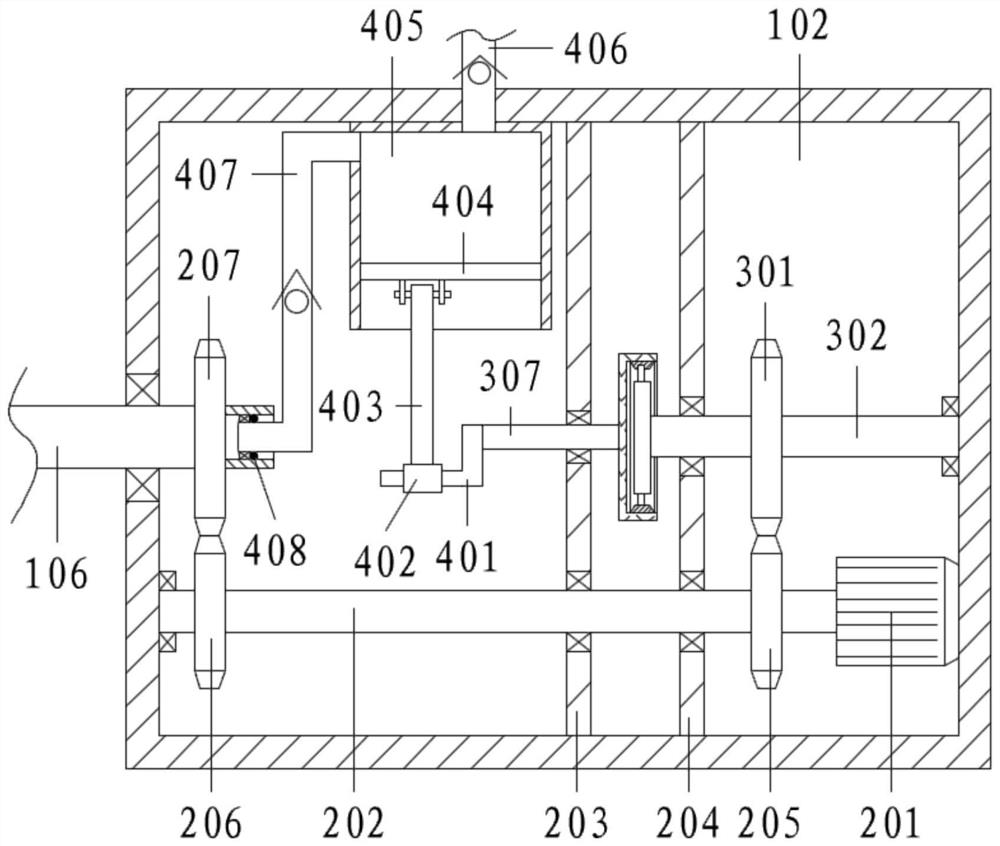

[0068] The bottom of the power box 102 is provided with a drive assembly 2, and the drive assembly 2 is provided with a servo motor 201 to drive; the handle 101 is equipped with a battery for powering the servo motor 201, and is provided with a switch for controlling the forward and reverse of the servo motor 201; the top of the power box 102 The self-switching assembly 3 and the exhaust assembly 4 are provided. The exhaust assembly 4 is located on the left side of the self-switching assembly 3; the ...

Embodiment 2

[0070] Referring to the accompanying drawings, a pipeline inner wall maintenance machine with cleaning and painting functions includes a handle 101, a power box 102, a paint storage tank 103, a fixed rod 104, a sealing cover 105 and a main shaft 106;

[0071] The top of the handle 101 is fixed with a power box 102; the paint storage tank 103 is connected above the power box 102 through a fixed rod 104, and the top of the paint storage tank 103 is screwed with a sealing cover 105;

[0072] The bottom of the power box 102 is provided with a drive assembly 2, and the drive assembly 2 is provided with a servo motor 201 to drive; the handle 101 is equipped with a battery for powering the servo motor 201, and is provided with a switch for controlling the forward and reverse of the servo motor 201; the top of the power box 102 The self-switching assembly 3 and the exhaust assembly 4 are provided. The exhaust assembly 4 is located on the left side of the self-switching assembly 3; the ...

Embodiment 3

[0096] In the above embodiments, the processing head 5 is only supported by the main shaft 106, and the main shaft 106 has a relatively large load.

[0097] Therefore, on the basis of the above-mentioned embodiment,

[0098] It also includes a reinforcement assembly 8; the reinforcement assembly 8 includes a pole 801, a slider 802 and an annular slide rail 803;

[0099] The outer wall on the left side of the power box 102 is fixed with an annular slide rail 803, and the annular slide rail 803 is coaxially arranged with the main shaft 106; the right side of the outer cylinder 501 is connected with a slider 802 through a strut 801, and the slider 802 and the annular slide rail 803 slide connect.

[0100] Specifically, when the outer cylinder 501 rotates, the sliding block 802 is also synchronously moved along the circular slide rail 803 through the support rod 801, and the support for the processing head 5 is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com