An automatic paint spraying device for steel pipes

A technology of automatic painting and steel pipe, applied in the direction of spraying device, spraying room, etc., can solve the problems of difficult operation of painting the inner wall of steel pipe, time-consuming and laborious, and difficulty in guaranteeing the uniformity of the automatic painting surface, so as to save manpower, expand the scope of application, improve the The effect of spray paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be clearly and completely described below in conjunction with the embodiments.

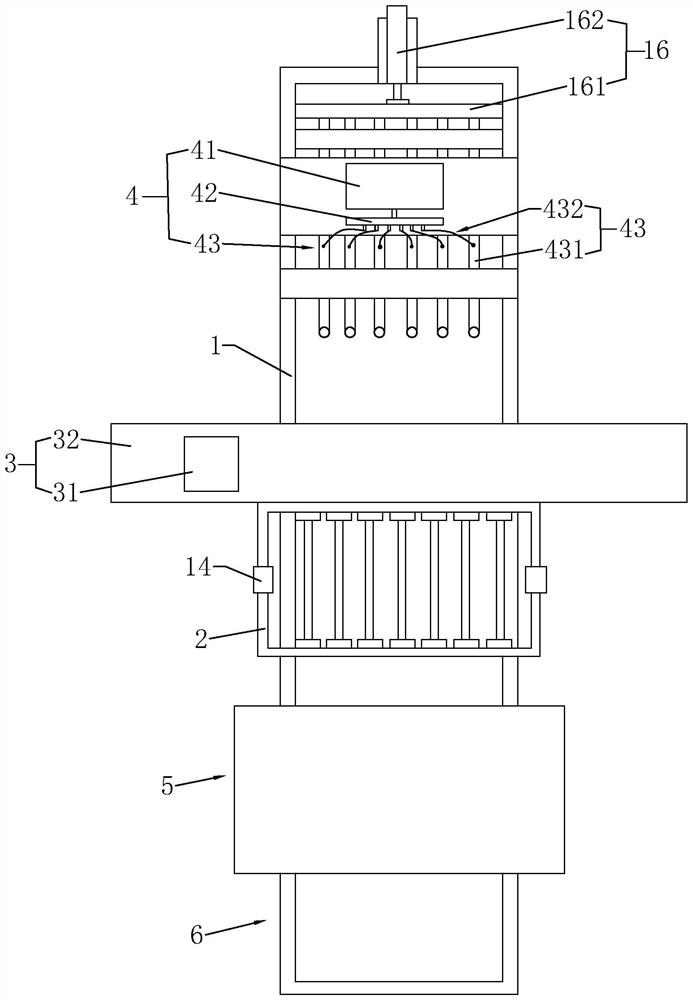

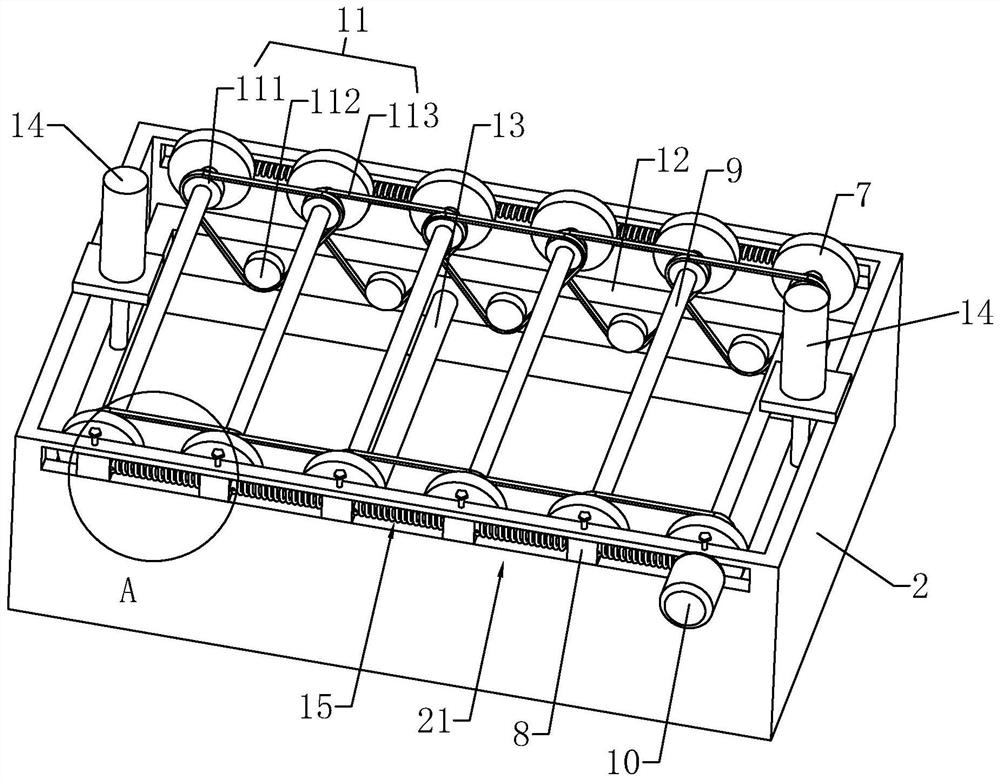

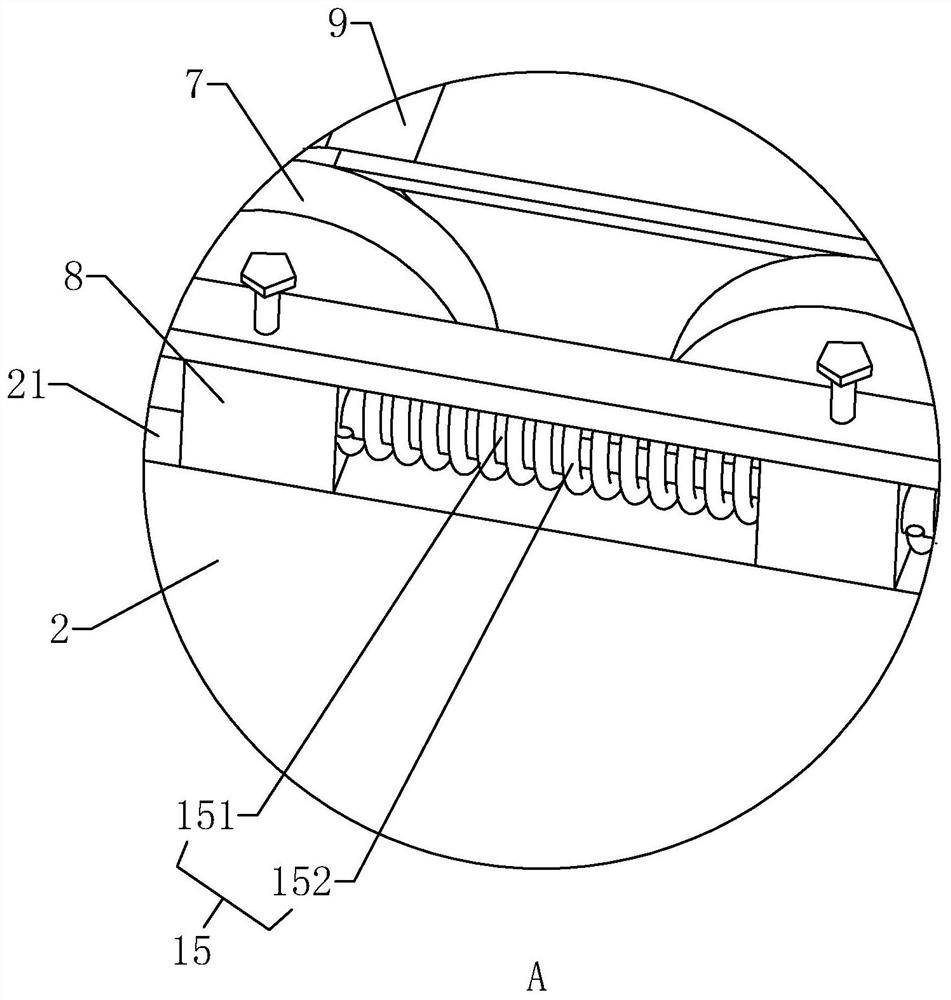

[0028] See attached figure 1 , a steel pipe automatic painting device, comprising a frame 1 and a bearing frame 2 horizontally erected on the frame 1; The sliding cooperation is realized through the pulley and the slide rail on the upper side of the frame 1, and at the same time, automatic walking is realized in the length direction of the frame 1 by means of a motor and a chain transmission mechanism.

[0029] The top of the frame 1 is provided with a first painting assembly 3, and one side of the length direction of the frame 1 is also provided with a second painting assembly 4; the first painting assembly 3 is mainly used for automatic painting of the outer wall of the steel pipe, while the second painting assembly Component 4 is mainly used for automatic painting of the inner wall of the steel pipe. At the same time, a drying area 6 and a packaging area 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com