Power supply control method of electric automobile

A technology for power supply control and electric vehicles, which is applied in the direction of electric vehicles, electrical devices, vehicle components, etc., can solve the problems of long waiting time for electric vehicles to start, achieve the effect of shortening the power-on time and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same parts.

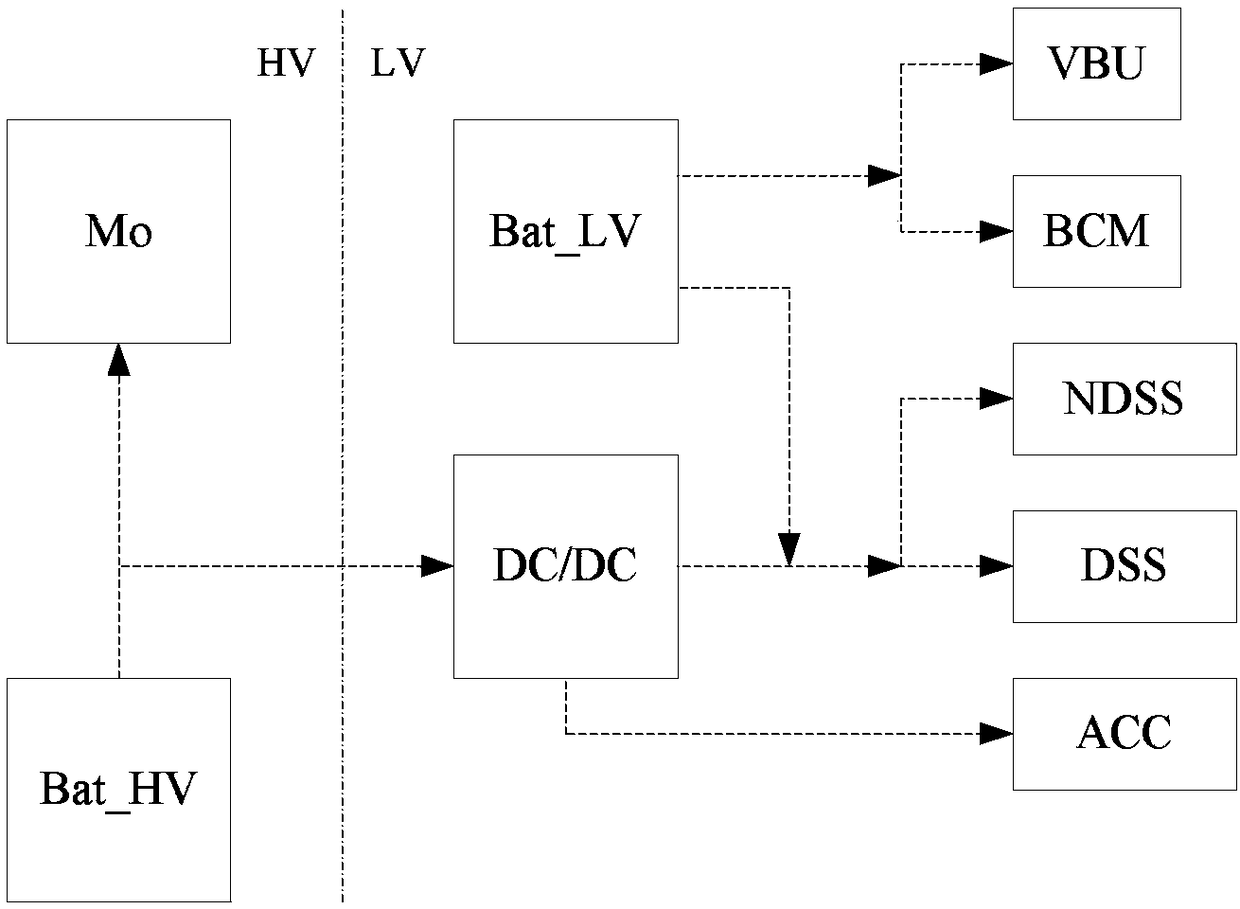

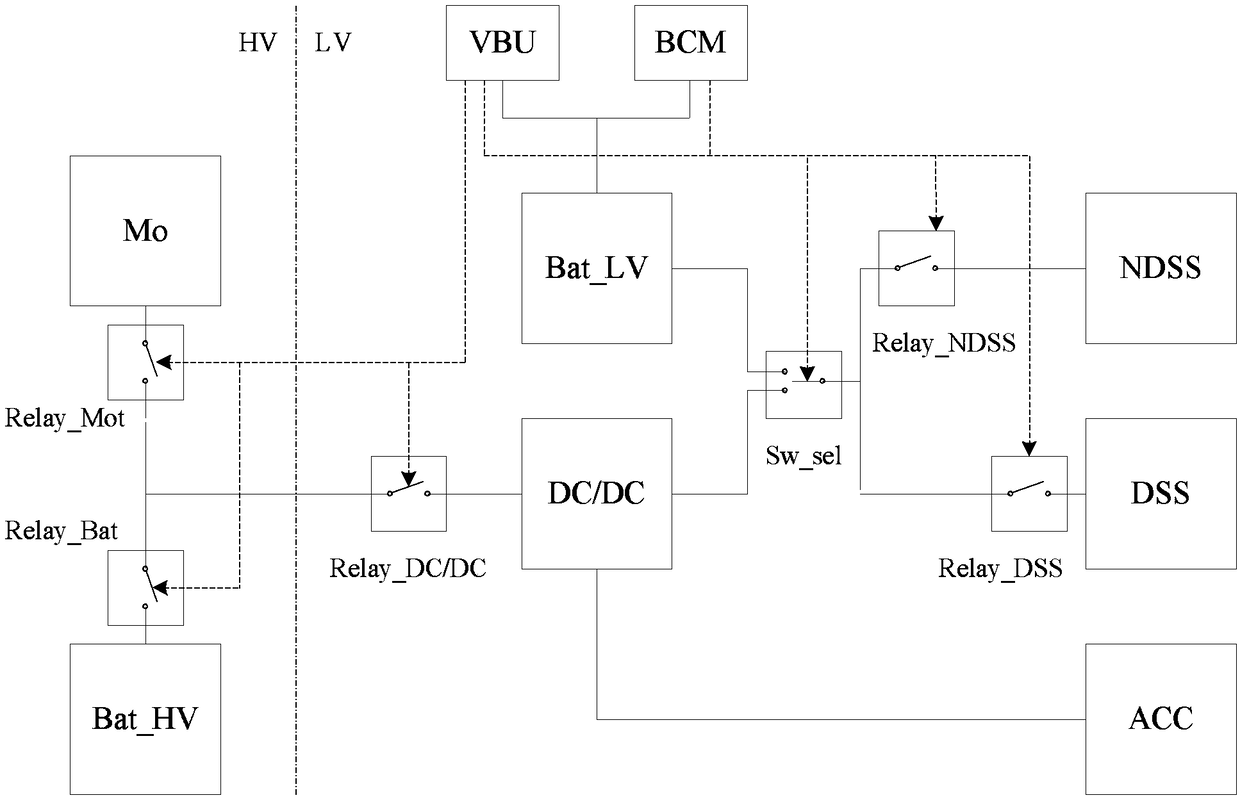

[0048]figure 1 Schematic diagram of the power supply relationship architecture for an electric vehicle. See figure 1 , electric vehicles can include power battery Bat_HV, voltage converter DC / DC, low-voltage battery Bat_LV (such as 12V battery), and VBU (Vehicle and Battery control Unit, vehicle and battery control unit) and BCM (Body Control Module, body control module ).

[0049] The power battery Bat_HV is used as a high-voltage power supply, which can provide high-voltage power supply to the motor Mo used as a power drive component of the electric vehicle.

[0050] The voltage converter DC / DC can realize the voltage conversion between the high-voltage domain HV where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com