Compact motor driven four-way reversal valve

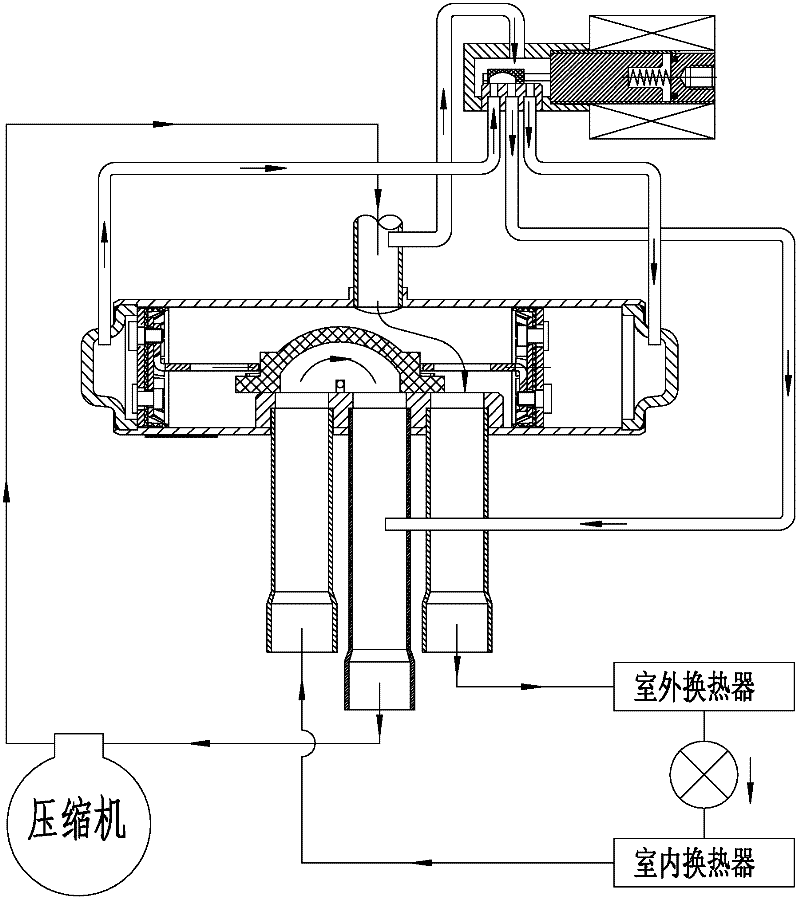

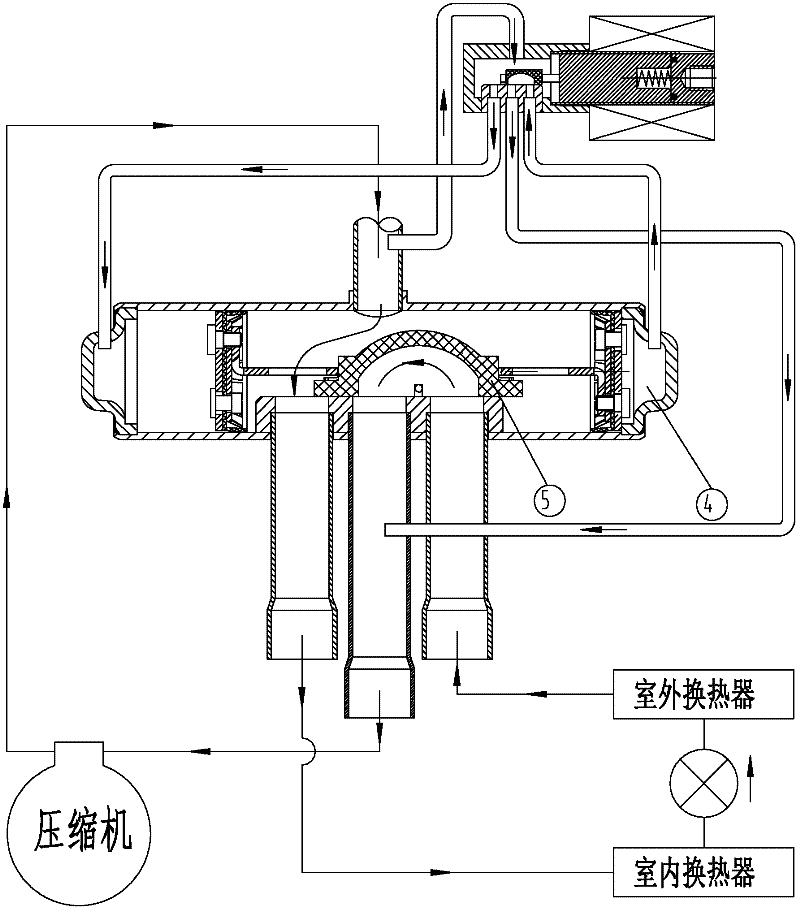

A four-way reversing valve, motor-driven technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problem that the reversing rotor of the four-way valve cannot be guaranteed to be in the correct working position and the timing of the reversing rotor action. , time and rotation angle control, the four-way valve does not have cost advantages and other issues, to achieve the effect of easy product quality assurance, saving the cost of the motor and the control circuit, and reducing the cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

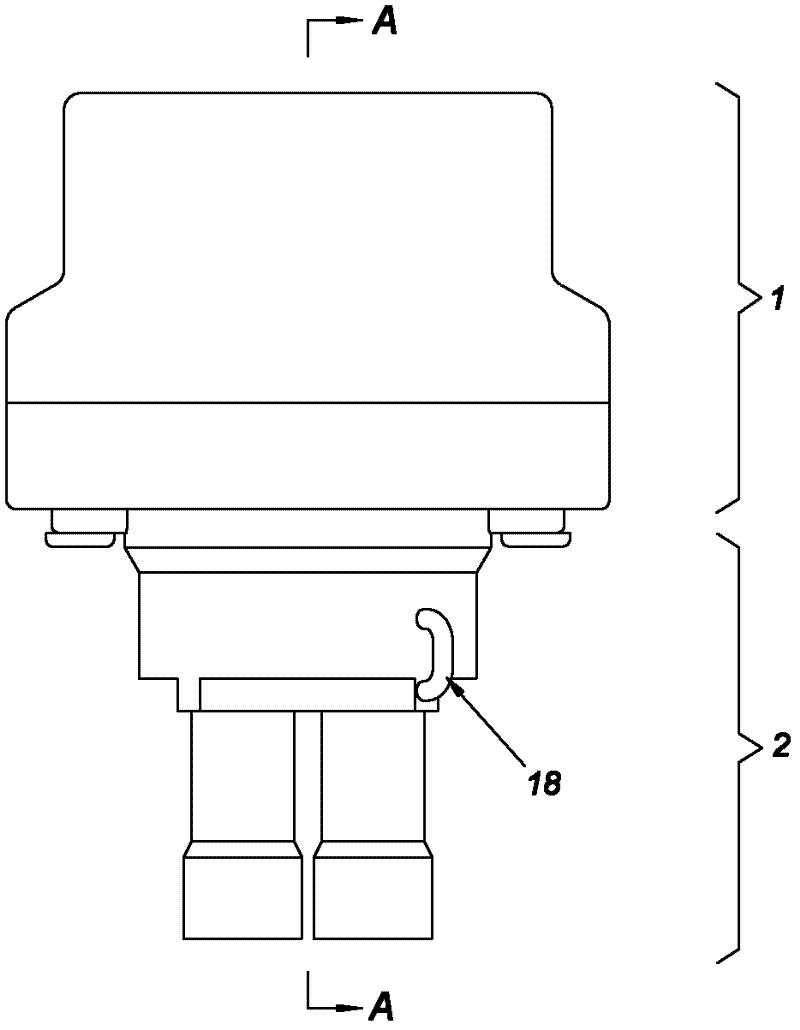

[0061] Such as Figure 16 , Figure 17 As shown, the difference between this embodiment and Embodiment 1 lies in that: the shape of the reversing rotor and the leading directions of the first nozzle, the second nozzle, the third nozzle and the fourth nozzle on the valve housing are different. Specifically: the reversing rotor 14' is integrated with the input shaft 15', and a partition 24' is formed on the reversing rotor 14'. The partition 24' is arranged along the diameter direction of the reversing rotor 14' and is perpendicular to The end face of the reversing rotor 14', the two sides of the partition plate 24' correspond to the two refrigerant channels 23' as the reversing rotor 14'; the first nozzle 19', the second nozzle 20', the third nozzle 21' and the fourth nozzle 24' are drawn out from the valve housing 12' in a direction perpendicular to the input shaft of the reversing rotor 14'. As shown in Figure 20, at this time, the reversing rotor 14' makes the first nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com